A Calculation Method for the Response of Surface Acoustic Wave Sensor with Non-uniform Load Distribution

A technology of load distribution and surface acoustic wave, applied in the direction of processing detection response signals, instruments, scientific instruments, etc., can solve problems such as difficult to meet requirements, uneven spatial distribution, and low accuracy of calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

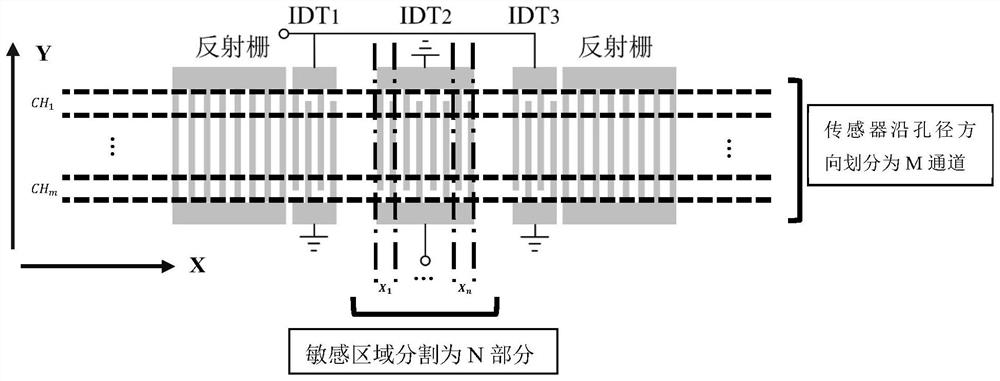

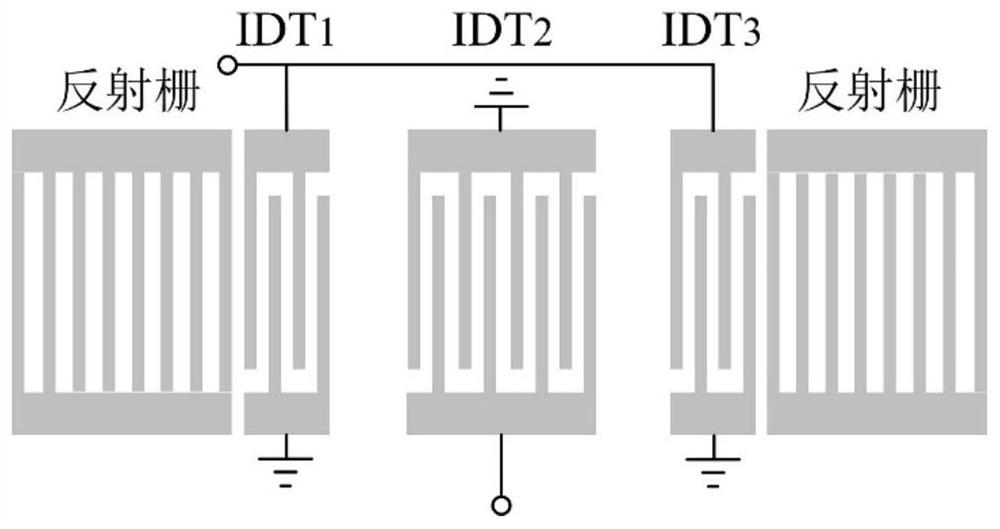

[0111] The method of the present invention for a two-terminal-pair SAW resonator-type sensor, such as figure 2 As shown in, for double-ended resonator type SAW sensor structure comprising: reflectors * 2, both sides of the transducer IDT1, IDT3, intermediate load transducer IDT2. IDT2 intermediate load transducer as sensitive area sensor.

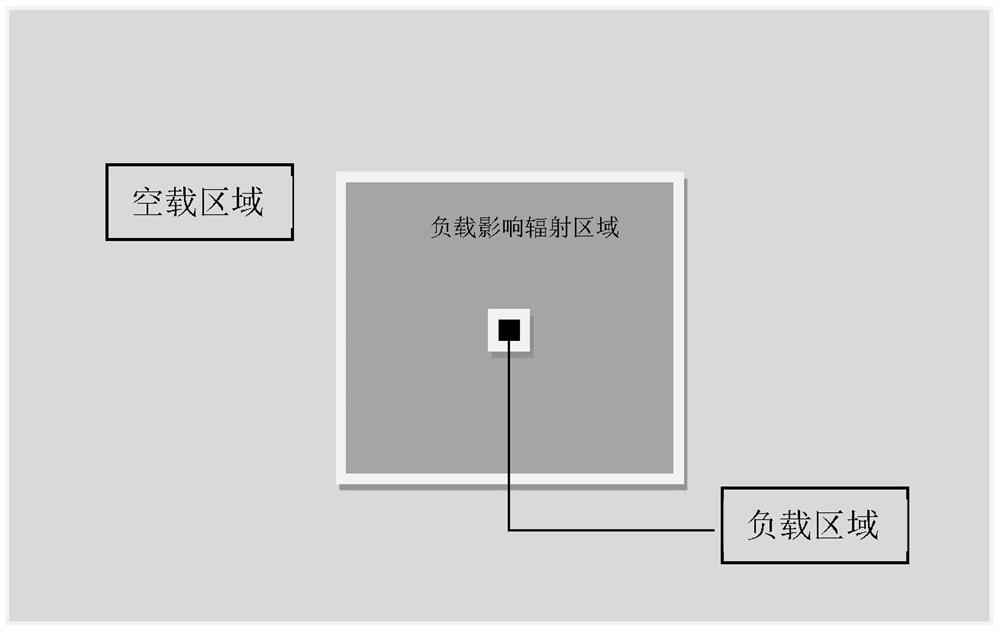

[0112] Example 1 Investigation case of uneven load spatial distribution embodiment, a particular case according to the actual application scenario value adjustment, in this calculation, the device is set to the total aperture 150 * Lambda (1 * Lambda = 10um), load size (adhesion area) to 10um 10um, loading effects of the radiation range to * 5 * Lambda (radius), the establishment of two-dimensional calculation model according to the above-described SAW parameters, such as image 3 Indicated.

[0113] Step1: Consider the load space SAW propagation direction (X-direction) distribution, such as Figure 4 As shown in the X direction, the sensor sensi...

Embodiment 2

[0131] Example 2 The SAW sensor such as the SAW sensor, such as the distribution of load properties, figure 2 As shown, the value of the specific case can be adjusted according to the actual application scenario, in this calculation, the total aperture of the device is 150 * lambda (1 * lambda = 10um), and the sensitive area is uniformly coated with both silica and zinc oxide. Different materials, such as Figure 8 Indicated.

[0132] Step1: Consider the spatial distribution of the load in the SAW propagation direction (X direction), in this embodiment, the load is uniformly distributed in the X direction, so it is not necessary to perform segmentation in the X direction.

[0133] Step2: Consider the space distribution of the load in the acoustic diameter direction (Y direction), such as Figure 9 and Figure 10 As shown in the Y direction, divide the SAW sensor into a portion of 2, and the number is one channel, the number is CH. 1 ~ Ch 2 In this embodiment, the parameters such as e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com