Polyamide composite material and preparation method and application thereof

A composite material and polyamide technology, applied in the field of composite materials, can solve problems such as no solution, and achieve the effect that the preparation method is simple and feasible, and is suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

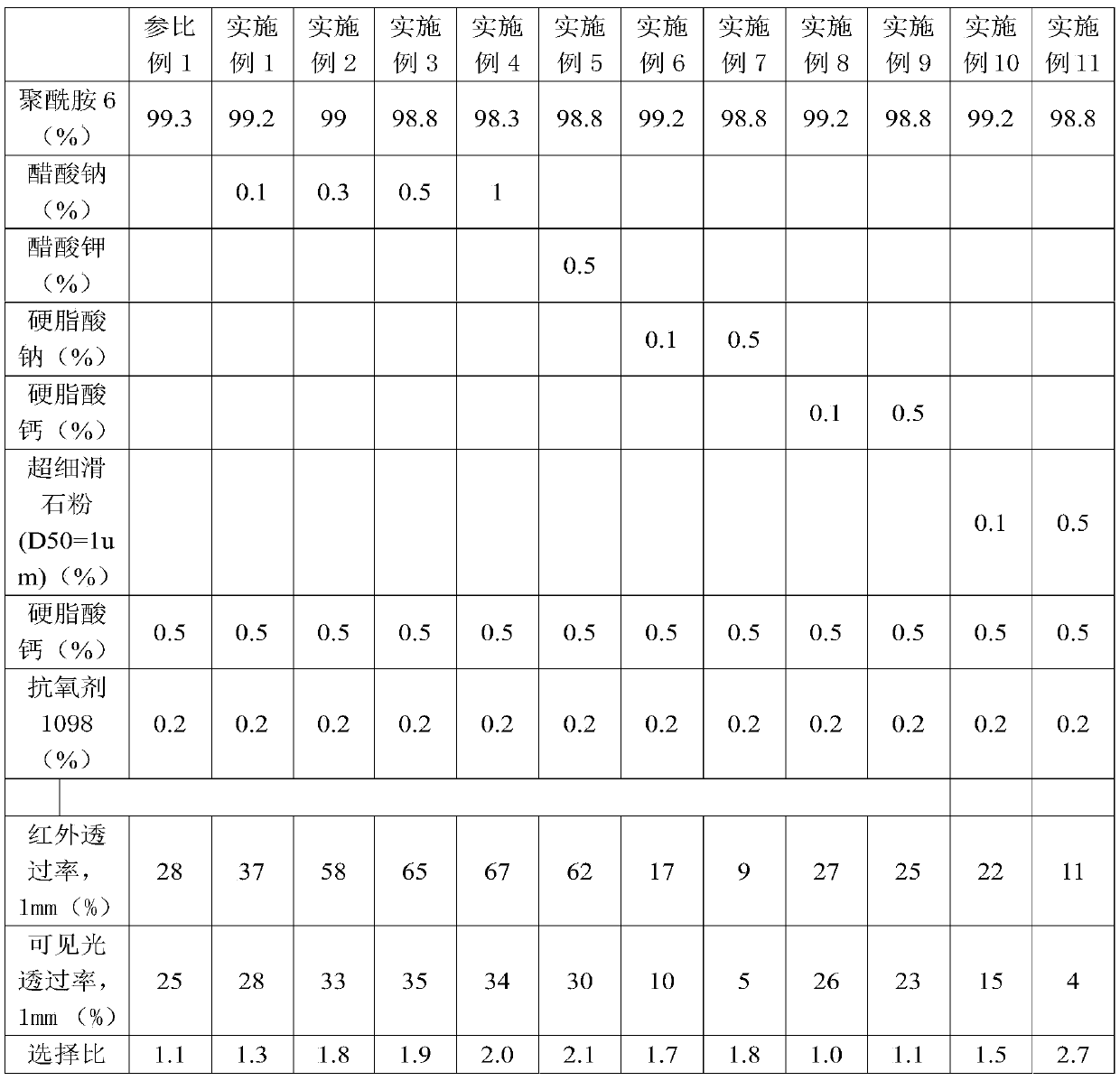

[0026] The polyamide composites in Examples 1 to 11 are mainly prepared by the following steps: Weigh the corresponding amount of components by weight percentage, then mix the components, and granulate them with a twin-screw extruder to obtain polyamide composites. The granulation temperature is 250~270℃. Wherein, the weight percentage of each component in Examples 1-11 and the transmittance of the prepared polyamide composite are shown in Table 1 below.

[0027] Table 1 The dosage of each component in Examples 1-11 and the permeability of the prepared polyamide composite

[0028]

[0029] In the experiment, the selectivity ratio was used as the main parameter to examine the selective transmittance of the material to infrared light and visible light. Define selectivity ratio = infrared light transmittance / visible light transmittance, the higher the selectivity ratio, the stronger the selectivity for infrared light and visible light. It can be seen from the experimental da...

Embodiment 12~22

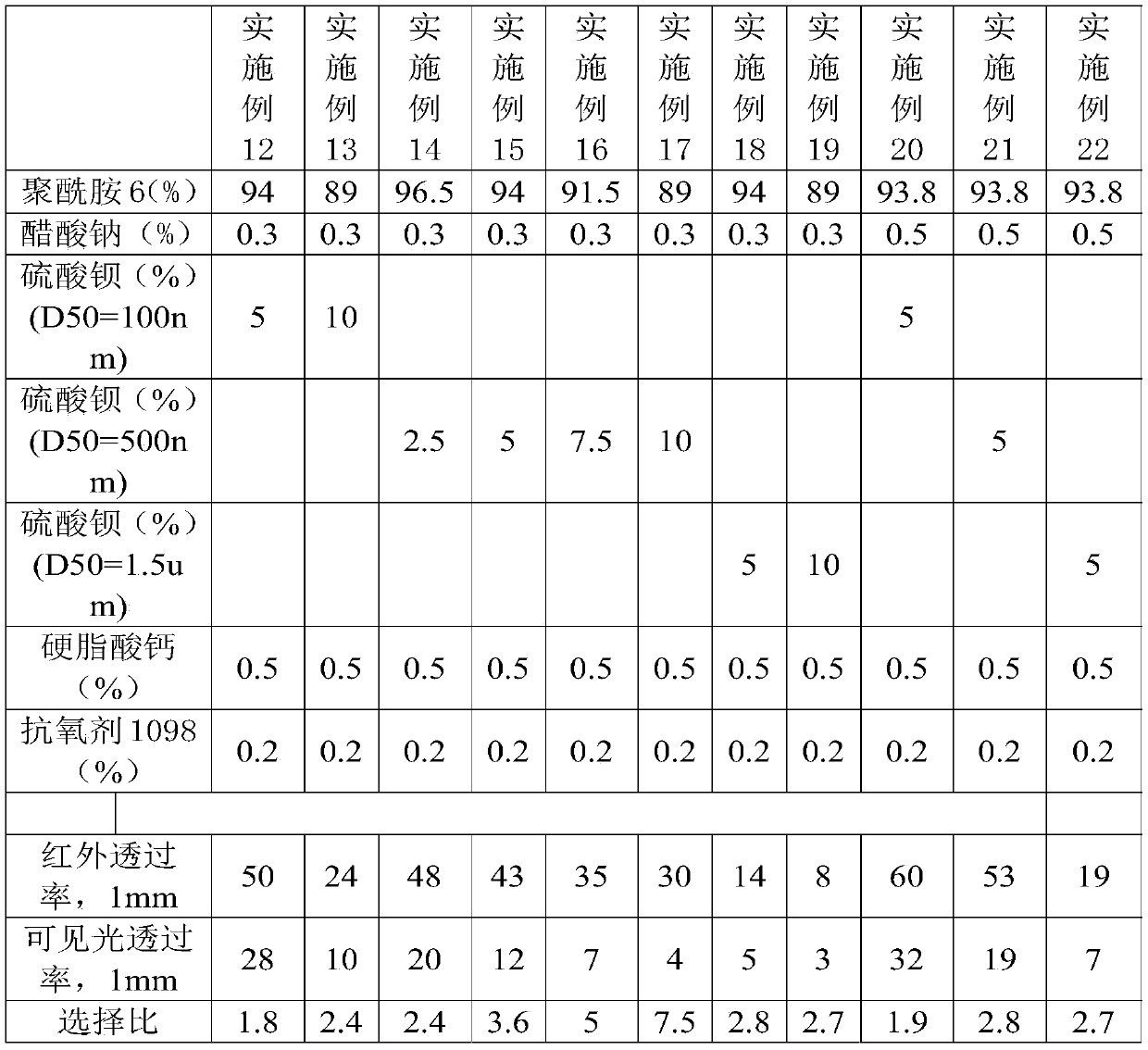

[0031] The polyamide composite materials in Examples 12 to 22 are mainly produced by the following steps: Weigh the corresponding amount of each component by weight percentage, then mix the components, and use a twin-screw extruder to granulate to obtain polyamide Compound, the granulation temperature is 250-270°C. Wherein, the weight percent of each component in Examples 12-22 and the transmittance of the obtained polyamide composite material are shown in Table 2.

[0032] Table 2 The weight percent of each component in Examples 12-22 and the transmittance of the obtained polyamide composite material

[0033]

[0034] It can be seen from Table 2 that when barium sulfate and sodium acetate with different particle sizes are used in combination, the selectivity ratios of almost all examples increase. Especially when barium sulfate with D50=500nm is used, the selectivity is greatly increased to more than 5, while the infrared transmittance remains above 30%, and the visible l...

Embodiment 23~26

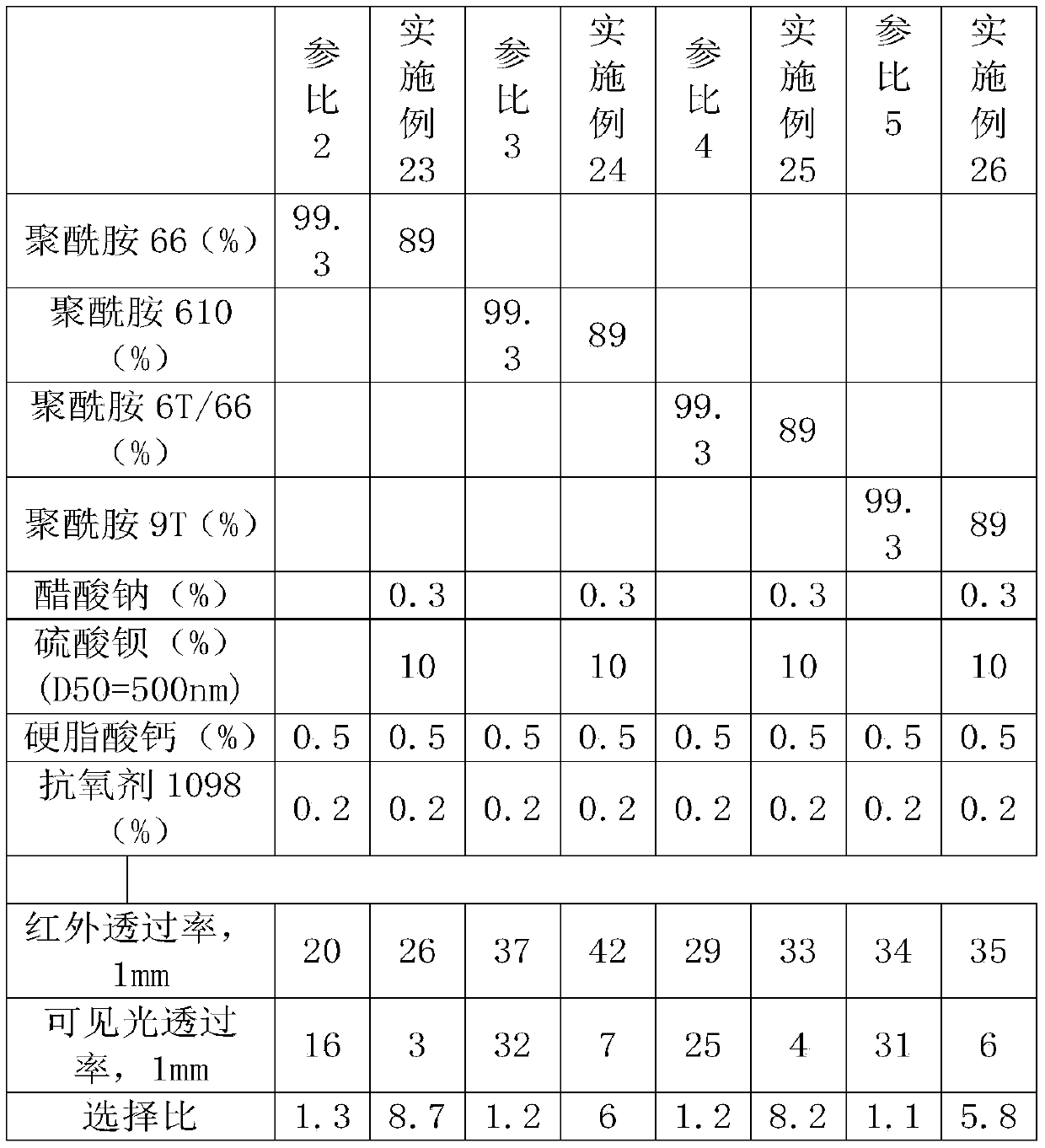

[0036] The polyamide composite materials in Examples 23 to 26 are mainly made by the following steps:

[0037] The respective components are weighed according to the weight percentage, and then the components are mixed and granulated by a twin-screw extruder to obtain a polyamide compound. The granulation temperature is 260-320°C. Wherein, the weight percentage of each component in Examples 23-26 and the transmittance of the obtained polyamide composite material are shown in Table 3.

[0038] Table 3 The weight percent of each component in Examples 23-26 and the transmittance of the obtained polyamide composite material

[0039]

[0040] It can be seen from the data in Table 3 that the combination of barium sulfate and sodium acetate is not only effective for PA6, but also effective for PA66, PA610, PA6T / 66 and PA9T. The infrared-visible selectivity ratio of each system has been greatly improved, while maintaining a high Infrared transmittance and low visible transmittance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com