Garbage gasification system and fuel gas manufacturing method

A gasification system and a gasification gas technology, applied in the field of waste gasification system, can solve the problems of high furnace temperature and low service life of a reaction furnace, and achieve high gasification efficiency, reduced carry-out and high carbon conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

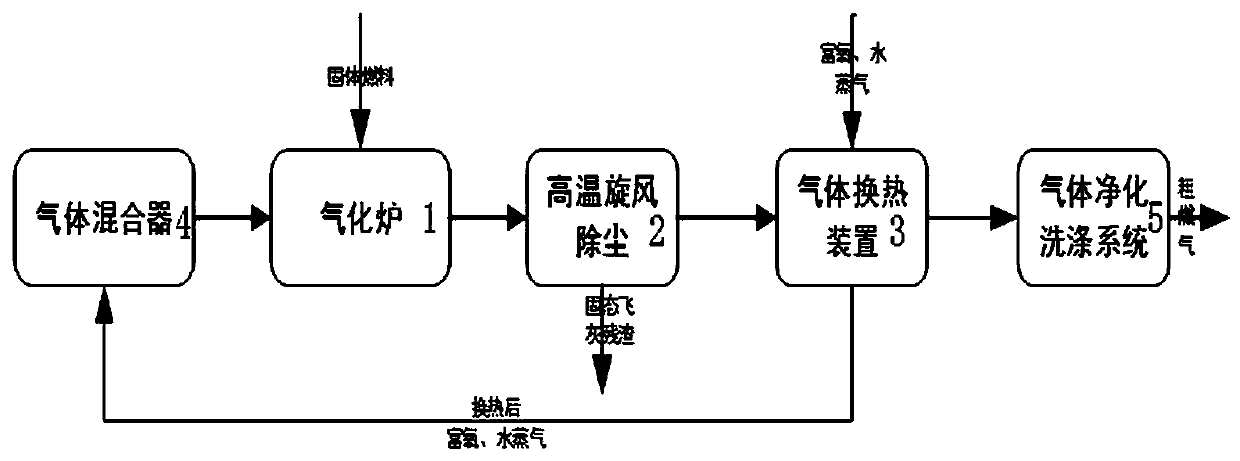

[0033] The garbage gasification system of the present invention includes: a gasifier body and its auxiliary equipment, high-temperature dust removal equipment, a heat exchanger, a gas purification and washing system, an oxygen generator, an air mixing device, a steam generator and a gas mixer.

[0034] The gasifier body and its auxiliary equipment are used for garbage gasification reaction.

[0035] The high-temperature dedusting equipment dedusts the gasification gas, and its gas inlet is connected to the gas outlet of the gasifier body.

[0036] The heat exchanger enables exothermic gas to exchange heat with endothermic gas, and its exothermic gas inlet is connected to the gas outlet of the high-temperature dust removal equipment.

[0037] The gas purification and scrubbing system scrubs and purifies the gasification gas, and its gas inlet is connected to the exothermic gas outlet of the heat exchanger.

[0038] The oxygen generator produces oxygen, and the oxygen is mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com