Electric shock repair treatment experimental method for hole defect of titanium alloy component

An experimental method and titanium alloy technology, applied in the field of titanium alloy structure repair, can solve the problems of high energy consumption and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] An experimental method for electrical shock repair treatment of pore defects in titanium alloy components, comprising the steps of:

[0014] 1) Preparation of experimental samples;

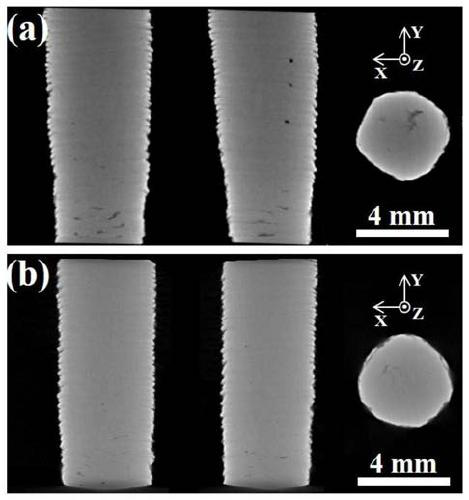

[0015] Using Ti-55531 powder as the raw material, a cylindrical titanium alloy sample (diameter Φ=4mm, height h=10mm) was obtained by laser direct forming additive manufacturing.

[0016] 2) Experimental process;

[0017] Place the additively manufactured cylindrical titanium alloy sample between the two electrodes of the electric shock treatment equipment, adjust the front-end input current and action time of the electric shock treatment equipment (current 70A, action time 0.08s), and perform electric shock treatment on the titanium alloy sample.

[0018] 3) Analysis of experimental results;

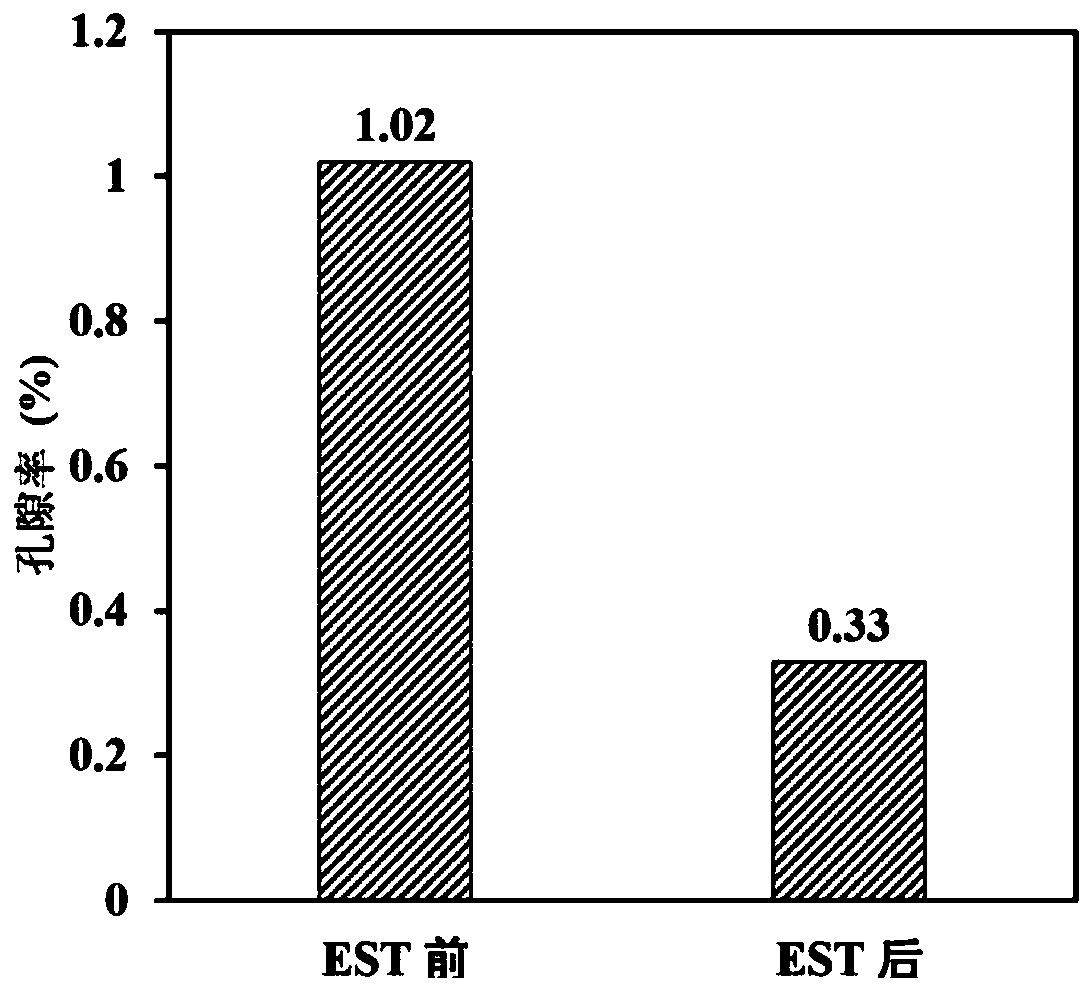

[0019] The changes in internal porosity of titanium alloy samples befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com