Multi-interface amorphous nanocrystalline electromagnetic shielding composite

A technology of amorphous nanocrystalline and composite materials, which is applied in the field of multi-interface amorphous nanocrystalline electromagnetic shielding composite materials and the preparation of the composite materials, can solve the problem of not being able to combine lightness and thinness, high shielding efficiency, high thermal stability, and high mechanical strength at the same time , It is difficult to realize the large-scale production of excellent multi-interface electromagnetic shielding materials, etc., to achieve the effects of excellent electromagnetic shielding performance, excellent electromagnetic shielding effect, and high magnetic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

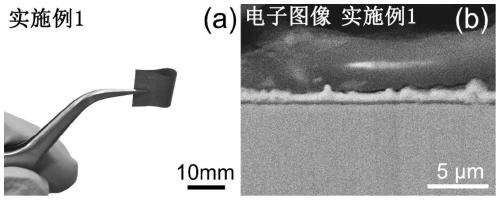

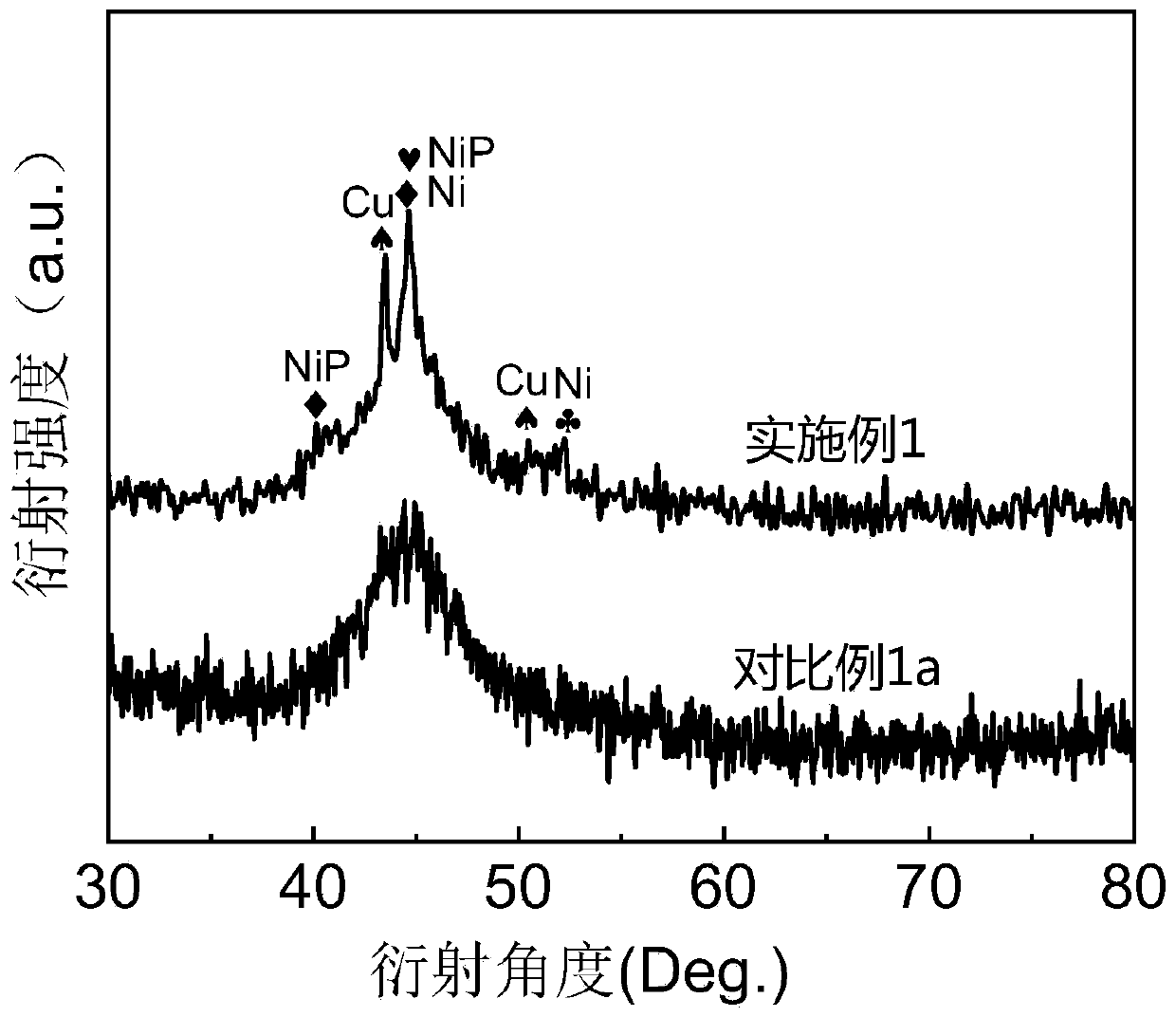

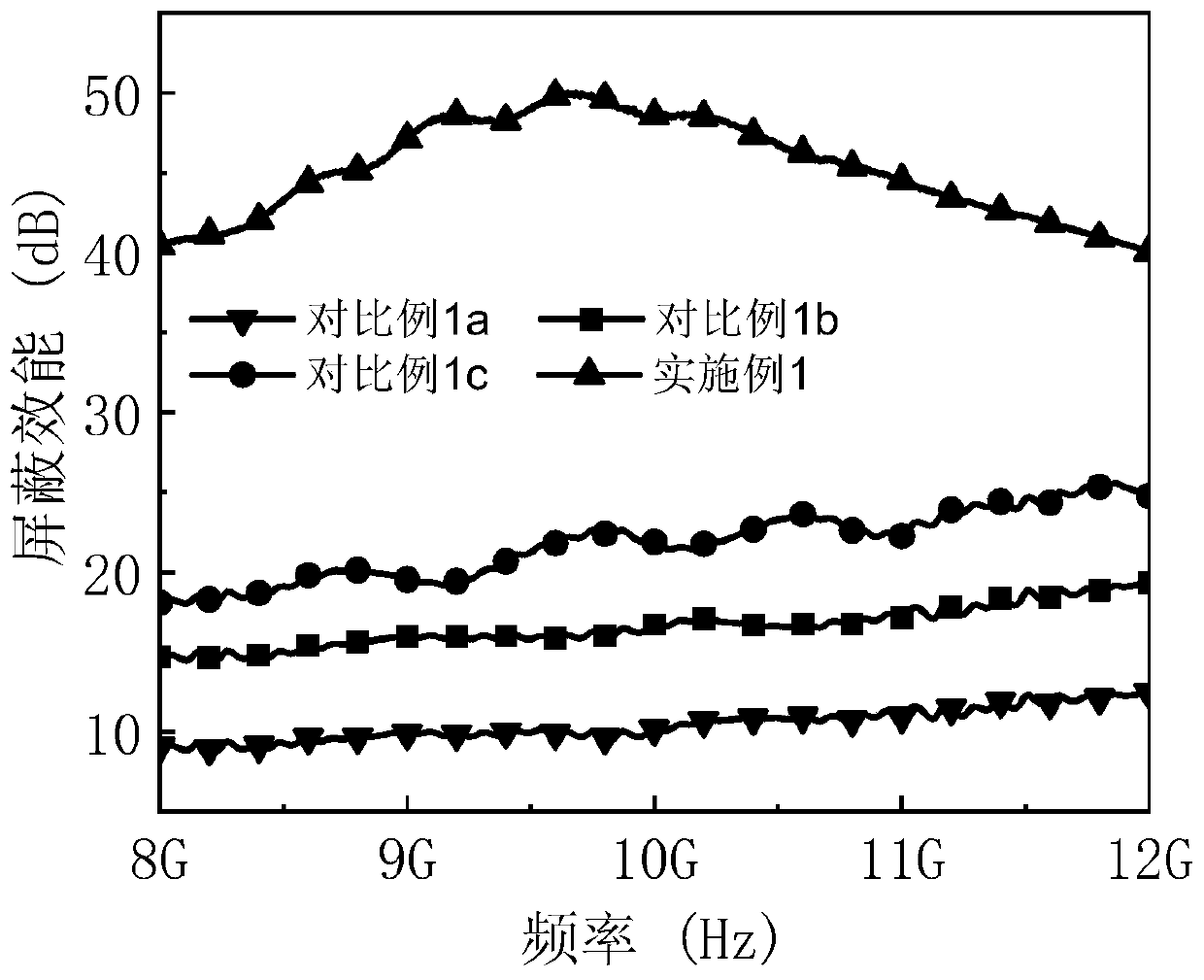

Embodiment 1

[0078] In this embodiment, the preferred magnetic permeability, coercive force, and saturation magnetic induction intensity are comprehensively excellent Fe-based amorphous alloy strips, and the specific composition is Fe 76 Si 13 B 8 Nb 2 Cu 1 .

[0079] The preparation method of the iron-based amorphous alloy strip is as follows:

[0080] (1) Prepare industrial-grade raw materials according to the required atomic percentage in the composition. The raw materials are shown in Table 1, and a master alloy ingot with uniform composition is prepared by using a vacuum induction furnace.

[0081] Table 1 raw material composition ratio

[0082] raw material Fe Si FeB FeNb Cu purity 98.4wt.% 99.6wt.% 99wt.% 99wt.% 99.95wt.% quality 22.73g 2.21g 2.97g 1.70g 0.39g

[0083] (2) The obtained master alloy ingot was ground with a grinding wheel to remove surface impurities, and then placed in a single-roll quenching device to obtain a t...

Embodiment 2

[0094] In this embodiment, the preferred Fe-based amorphous alloy strip with excellent saturation magnetic induction performance, the specific composition is Fe 84.3 Si 4 B 8 P 3 Cu 0.7 .

[0095] The preparation method of the iron-based amorphous alloy strip is as follows:

[0096] (1) Prepare industrial-grade raw materials according to the atomic percentage in the required composition. The raw materials are shown in Table 2, and a master alloy ingot with uniform composition is prepared by using a vacuum induction furnace.

[0097] Table 2 raw material composition ratio

[0098] raw material Fe Si FeB FeP Cu purity 98.4wt.% 99.6wt.% 99wt.% 99wt.% 99.95wt.% quality 23.50g 2.21g 2.75g 2.25g 0.39g

[0099] (2) The obtained master alloy ingot was ground with a grinding wheel to remove surface impurities, and then placed in a single-roll quenching device to obtain a thin iron-based amorphous alloy strip with a thickness of 17 ...

Embodiment 3

[0109] In this embodiment, the Fe-based amorphous alloy strip with excellent magnetic permeability is preferred, and the specific composition is Fe 77 Si 10 B 9 Nb 2 Cu 1 Al 1 .

[0110] The preparation method of the iron-based amorphous alloy strip is as follows:

[0111] (1) Prepare industrial-grade raw materials according to the required atomic percentage in the composition. The raw materials are shown in Table 3, and a master alloy ingot with uniform composition is prepared by using a vacuum induction furnace.

[0112] Table 3 raw material composition ratio

[0113]

[0114]

[0115] (2) The obtained master alloy ingot was ground with a grinding wheel to remove surface impurities, and then placed in a single-roll quenching device to obtain a thin iron-based amorphous alloy strip with a thickness range of 18 μm.

[0116] Get the composition as Fe 77 Si 10 B 9 Nb 2 Cu 1 Al 1 The iron-based amorphous thin strips were placed in SnCl with a concentration of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com