Device for preparing aluminum from gaseous aluminum chloride through molten salt electrolysis and aluminum chloride feeding method

A technology of molten salt electrolysis and aluminum chloride, applied in the field of electrolytic aluminum, can solve the problems of increasing labor intensity of workers, environmental pollution, etc., and achieve the effects of fast dissolution speed, low energy consumption, and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

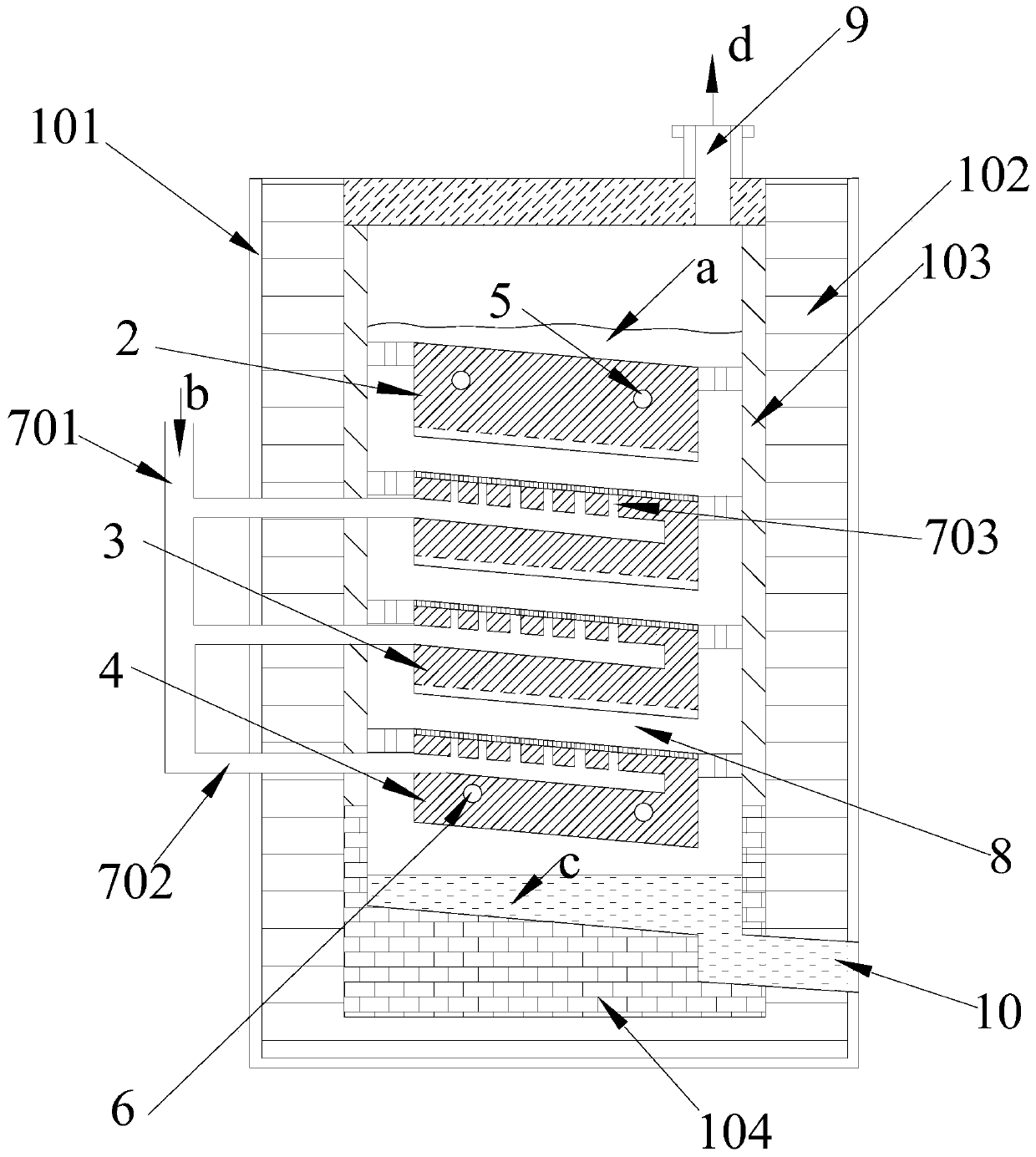

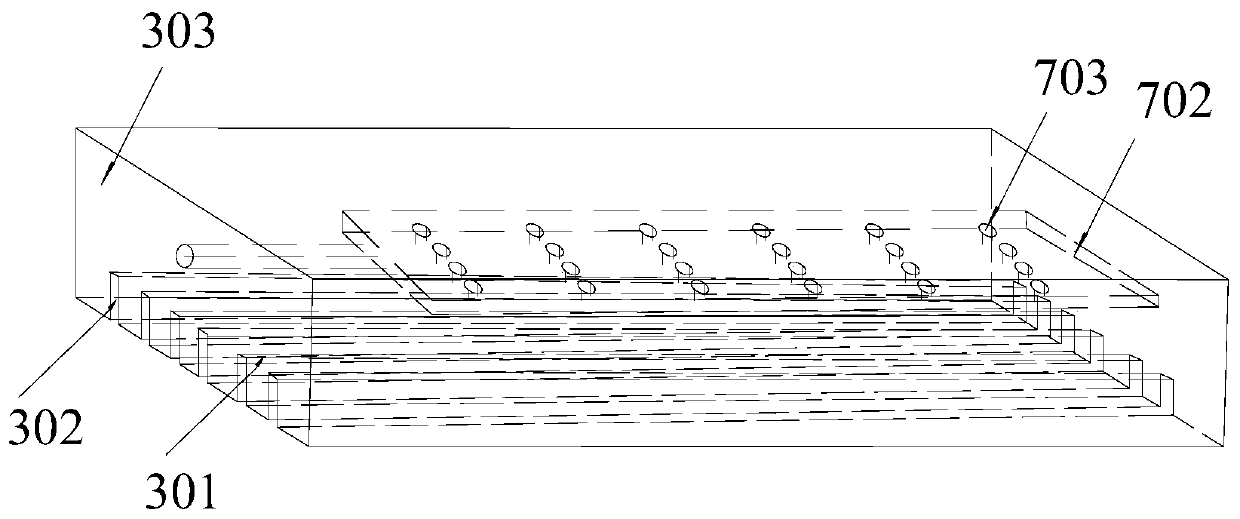

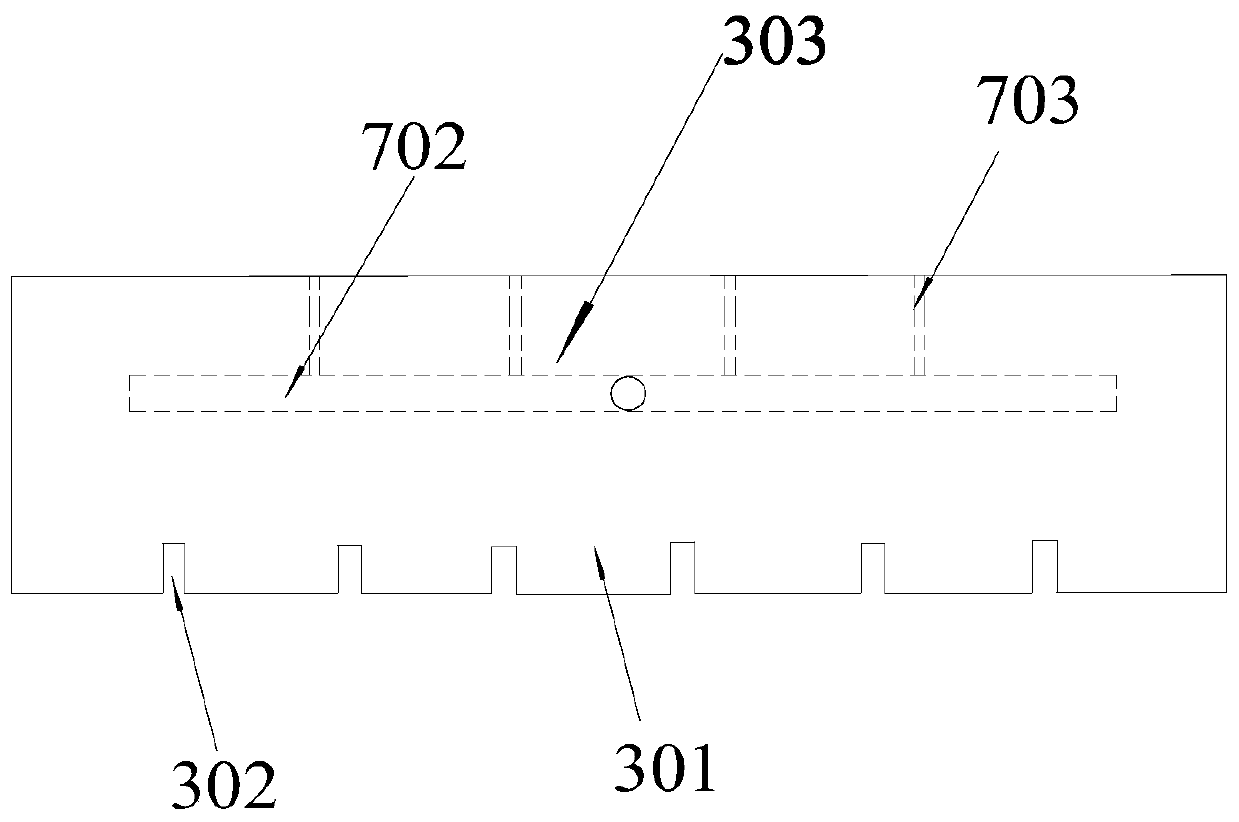

[0041] A device for preparing aluminum by electrolysis of molten salt using gaseous aluminum chloride as raw material, which has a square electrolytic cell structure, such as figure 1 As shown, the device for preparing aluminum by molten salt electrolysis using gaseous aluminum chloride as raw material includes a shell, the shell is made of double-layer material, the outer layer is a stainless steel layer 101, and the inner layer of the stainless steel layer 101 is lined with refractory bricks, which are made of non-conductive It is made of insulating material and has certain corrosion resistance to the chloride system. The lower part of the device for producing aluminum by molten salt electrolysis using gaseous aluminum chloride as raw material is the aluminum storage area, which is used to store the liquid aluminum flowing down from the cathode. In the aluminum storage area, the bottom and side walls of the shell are made of carbon material layer 104, and the carbon material...

Embodiment 2

[0054] A device for preparing aluminum by electrolysis of molten salt using gaseous aluminum chloride as raw material, which is a cylindrical electrolytic cell, and its structural cross-section schematic diagram is shown in Figure 4 , including a shell, the shell is a double-layer material, the outer layer is a stainless steel layer 101, the present embodiment uses a steel layer, and the inner layer is an insulating layer 102, and the insulating layer material used in this embodiment is refractory brick.

[0055] The housing is airtight to form a cavity. A chlorine gas outlet 9 is provided at the upper end of the housing. The lower part of the housing cavity is an aluminum storage area. A carbon material layer 104 is provided on the inner wall of the cavity of the aluminum storage area. The side wall of the shell is provided with an aluminum outlet 10; the cavity above the aluminum storage area is an electrolysis area, and a non-conductive refractory material layer 103 is arra...

Embodiment 3

[0068] A kind of device that uses gaseous aluminum chloride as raw material molten salt electrolysis to prepare aluminum, the same as embodiment 1, the difference is:

[0069] The electrolyte solvent used in this embodiment is LiCl-CaCl containing 16% by mass of LiCl and 5% by mass of LiF. 2 -LiF mixed molten salt, the electrolysis temperature is 670-690°C, the pole distance is 10mm, the structure diagram is shown in Figure 8 , the specific structure is different in:

[0070] (1) An aluminum outlet pipeline is arranged in the channel left on the plate electrode and the inner surface of the shell. The aluminum outlet of the aluminum outlet pipeline is set in the aluminum storage area and immersed in the metal liquid aluminum. The aluminum outlet of the aluminum outlet pipeline It is arranged outside the housing cavity, and the aluminum outlet pipeline passes through the outlet provided above the housing. The aluminum outlet of the aluminum outlet pipeline is connected with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com