Waxing device for fabric production

A cloth and wax roller technology, which is applied in the field of waxing devices for cloth production, can solve the problems of poor wax coating effect on the cloth surface, and achieve the effects of accelerating wax melting speed, improving mixing uniformity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

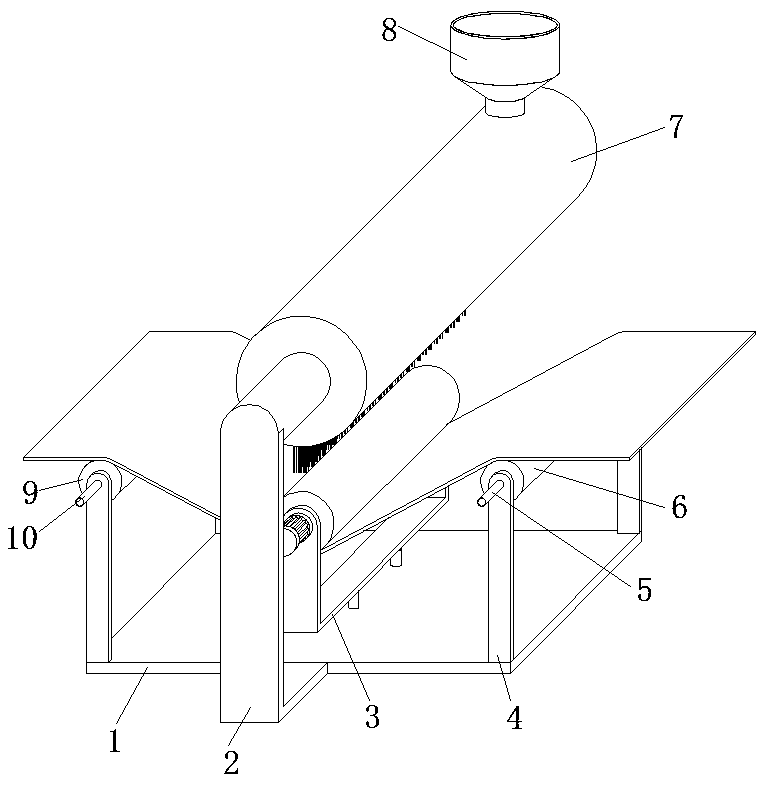

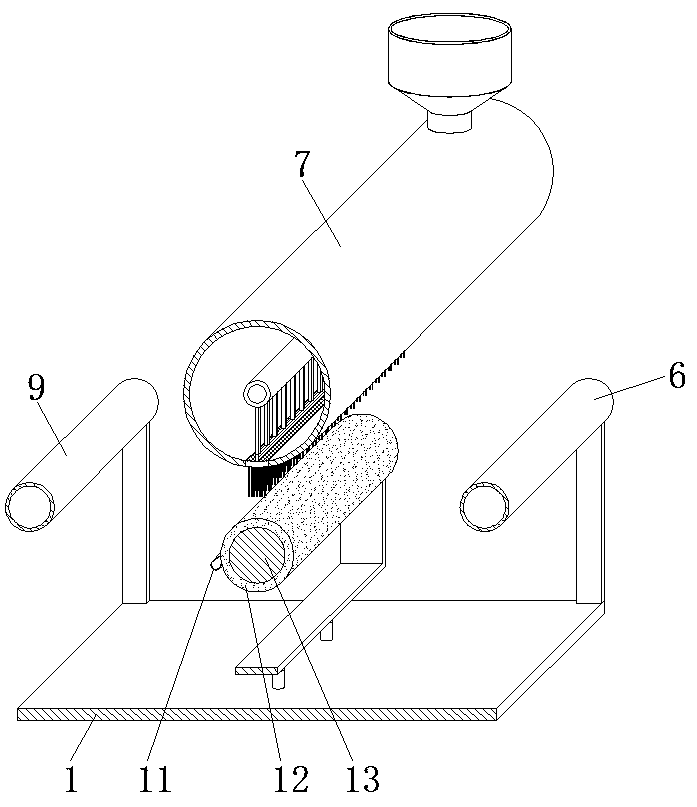

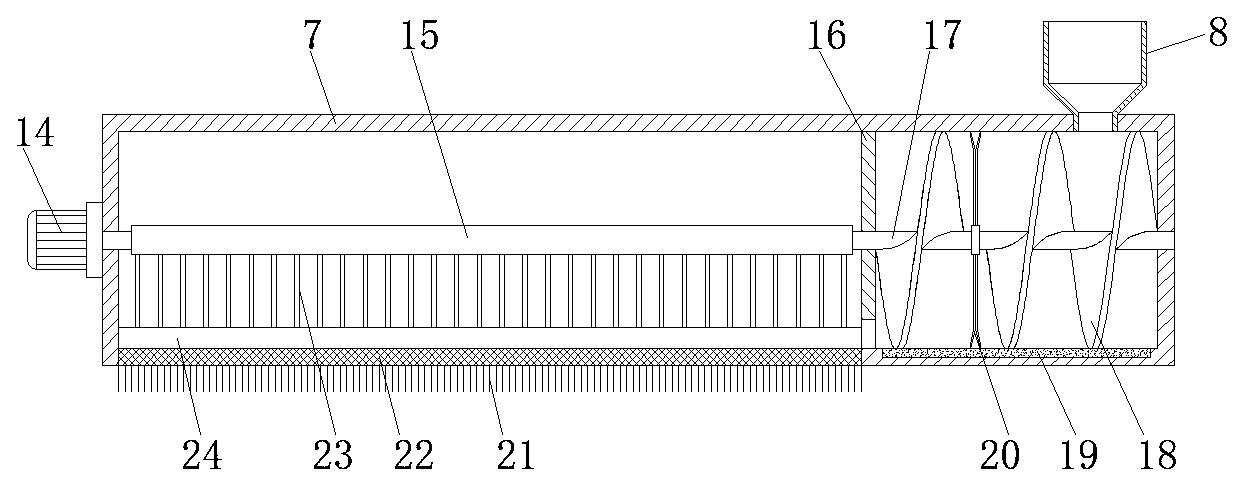

[0032] refer to Figure 1-5 , a waxing device for cloth production, comprising a base 1, a fixing frame 2 is welded on one side of the outer wall of the base 1, and a feeding box 7 is fixed on one end of the outer wall of the fixing frame 2 by screws, and a support is welded in the middle of the top outer wall of the base 1 tube 27, and the inner wall of the support tube 27 is slidably connected with a slide rod 29, the same support spring 28 is welded between the bottom outer wall of the slide rod 29 and the bottom inner wall of the support tube 27, and the top outer wall of the slide rod 29 is welded with a lifting frame 3, which can be lifted The inwall of frame 3 has waxing roller installation hole, and the inwall of waxing roller installation hole is connected with waxing roller 13 by bearing, and the outer wall of waxing roller 13 is fixed with waxing brush 12 by screw, and waxing brush 12 is positioned at Just below the feeding box 7, a side outer wall of the elevating ...

Embodiment 2

[0043] refer to Figure 1-5 , a waxing device for fabric production, the inner walls of both sides of the lifting frame 3 are provided with slider chute, and the inner wall of the slider chute is slidably connected with a slider 31, the bottom outer wall of the slider 31 and the slider chute A connecting spring 30 is welded between the bottom inner walls of the two sliders 31, and the opposite side outer walls of the two slide blocks 31 are provided with pressure roller installation holes, and the inner walls of the pressure roller installation holes are connected with pressure rollers 32 through bearings.

[0044] During use, the slider 31 is supported upward by the connecting spring 30 to push the pressure roller 32 to cover the bottom outer wall of the waxing brush 12 to ensure effective contact between the cloth and the waxing brush 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com