Method for improving dryness of deep well thickened oil well bottom steam through electric heating

A technology of electric heating and steam, applied in wellbore/well parts, earthwork drilling, production fluid, etc., can solve problems such as poor development effect, difficulty in obtaining economic benefits of heavy oil, low steam dryness, etc., and reduce production cost , Reduce the volume of invalid condensed water, and the effect of high heat enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

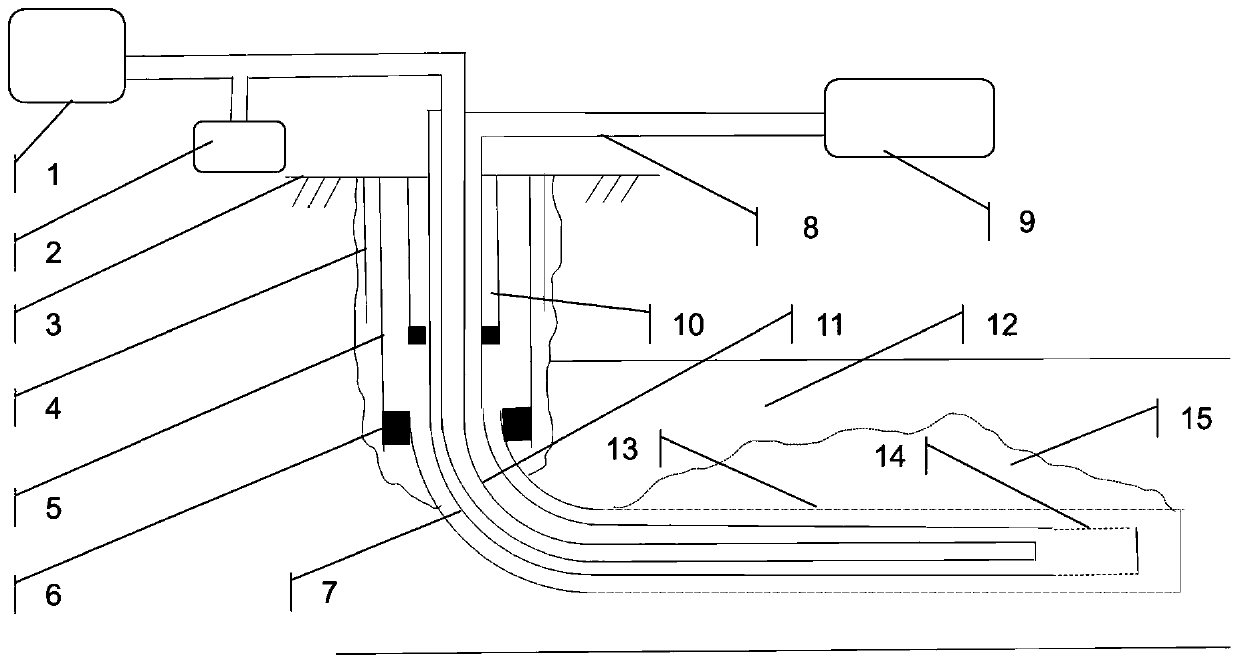

[0024] Further illustrate the present invention according to accompanying drawing and embodiment below.

[0025] The thermal efficiency of the steam boiler is 85%, the injection rate is 200t / d (cold water equivalent), the boiler is 500m away from the wellhead, the dryness of the steam outlet of the boiler system on the ground is 75%, and the dryness of the steam separated by the ground steam-water separator is 95%. The surface steam injection pipeline injects, and the injection rate is 157.9t / d. The steam injection pressure is 4MPa, and the steam injection temperature is 250°C.

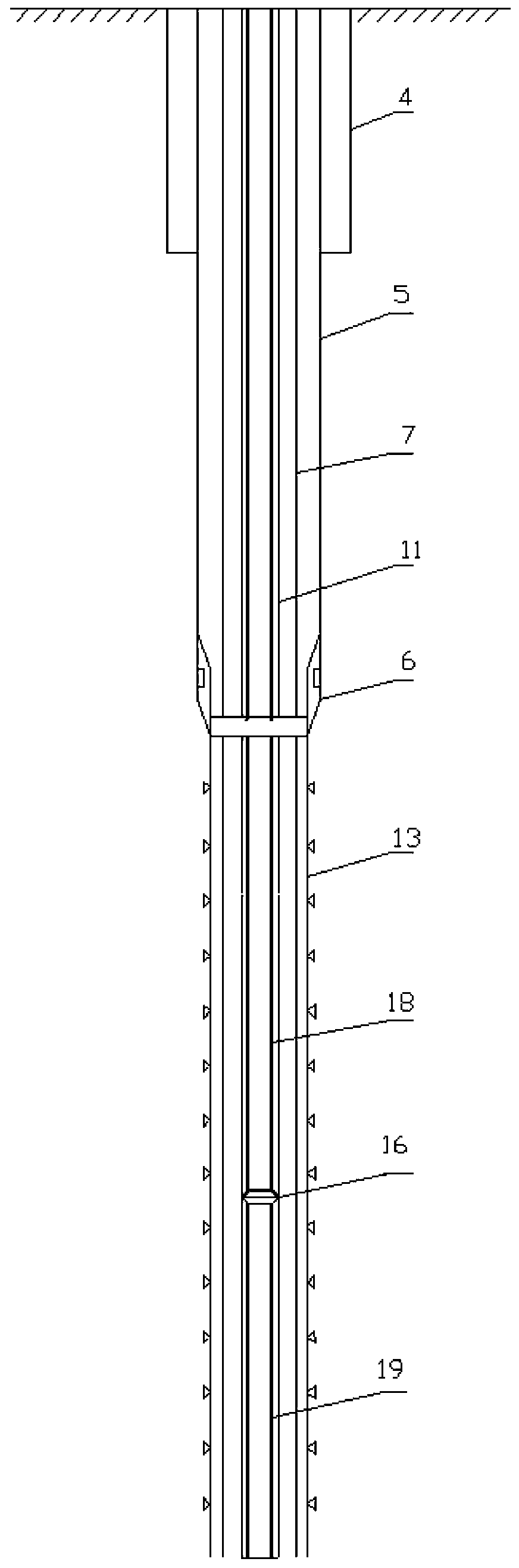

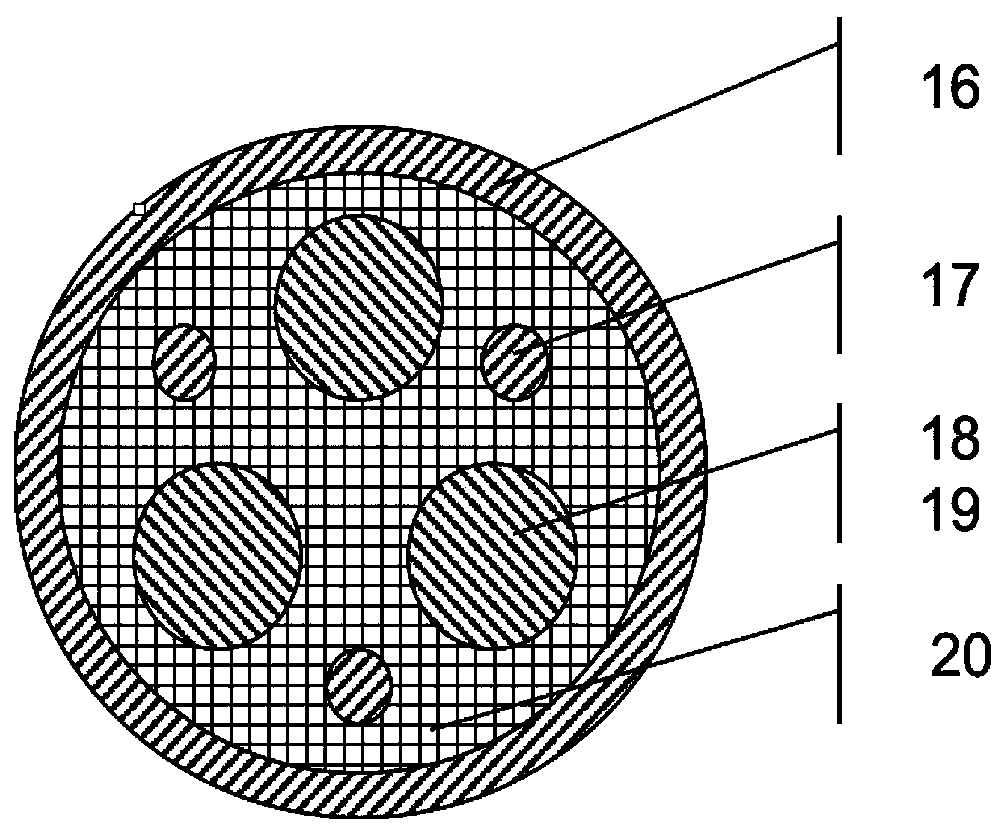

[0026] see figure 1 , image 3 .

[0027] The steam generated by the boiler system 9 located on the ground 3 is injected through the ground steam injection pipeline 8, and the lower part of the production casing 5 in the surface casing 4 is connected with the oil layer screen 13 located in the oil layer 12 with the hanger 6. The oil layer has a steam chamber 15 and Steam outlet flower pipe 14; In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com