Method for increasing heat enthalpy value of sodium sulfate decahydrate

A technology of sodium sulfate decahydrate and sodium sulfate, which is applied in the field of phase change energy storage materials and its preparation, can solve the problems of supercooling, non-uniform melting, phase change enthalpy attenuation, etc., and achieve the effect of high enthalpy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Example: A method for improving the enthalpy value of sodium sulfate decahydrate, according to the following steps:

[0019] (1) Take industrial-grade raw material sodium sulfate to prepare a saturated aqueous solution, filter to remove insoluble impurities, and obtain a saturated aqueous solution of sodium sulfate;

[0020] (2) Take industrial-grade manganese nitrate raw materials to prepare a saturated aqueous solution, filter to remove insoluble impurities, and obtain a saturated aqueous solution of manganese nitrate;

[0021] (3) Mix 80ml of saturated aqueous solution of sodium sulfate in step (1) with 20ml of saturated aqueous solution of manganese nitrate in step (2);

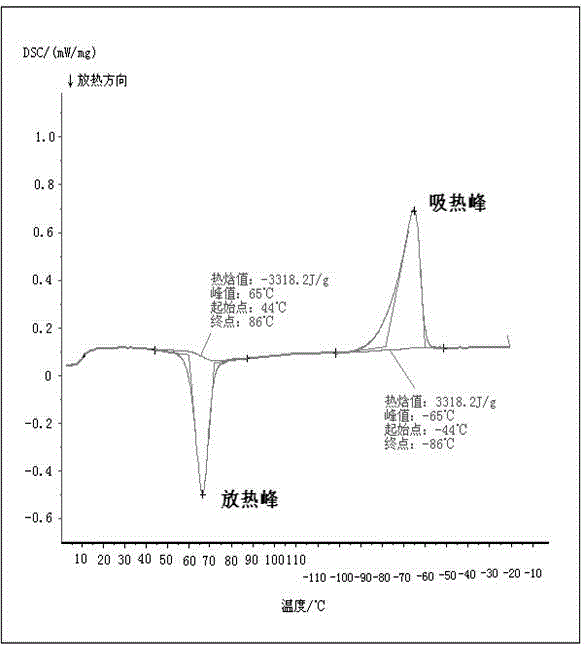

[0022] (4) Slowly add the mixed solution of step (3) into 100ml of absolute ethanol, a brown-black precipitate is precipitated, filtered, and dried at room temperature to obtain 5g of the product, and the measurement results are shown in the accompanying drawings;

[0023] (5) Ethanol is recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com