System for measuring inclination angle of wind power tower based on three-dimensional Hall sensor

A Hall sensor, wind measurement technology, applied in the direction of measuring inclination, measuring device, instrument, etc., can solve the problems of poor repeatability, increased detection cost, large accumulated absolute error, etc., to avoid false signals, accuracy High, repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

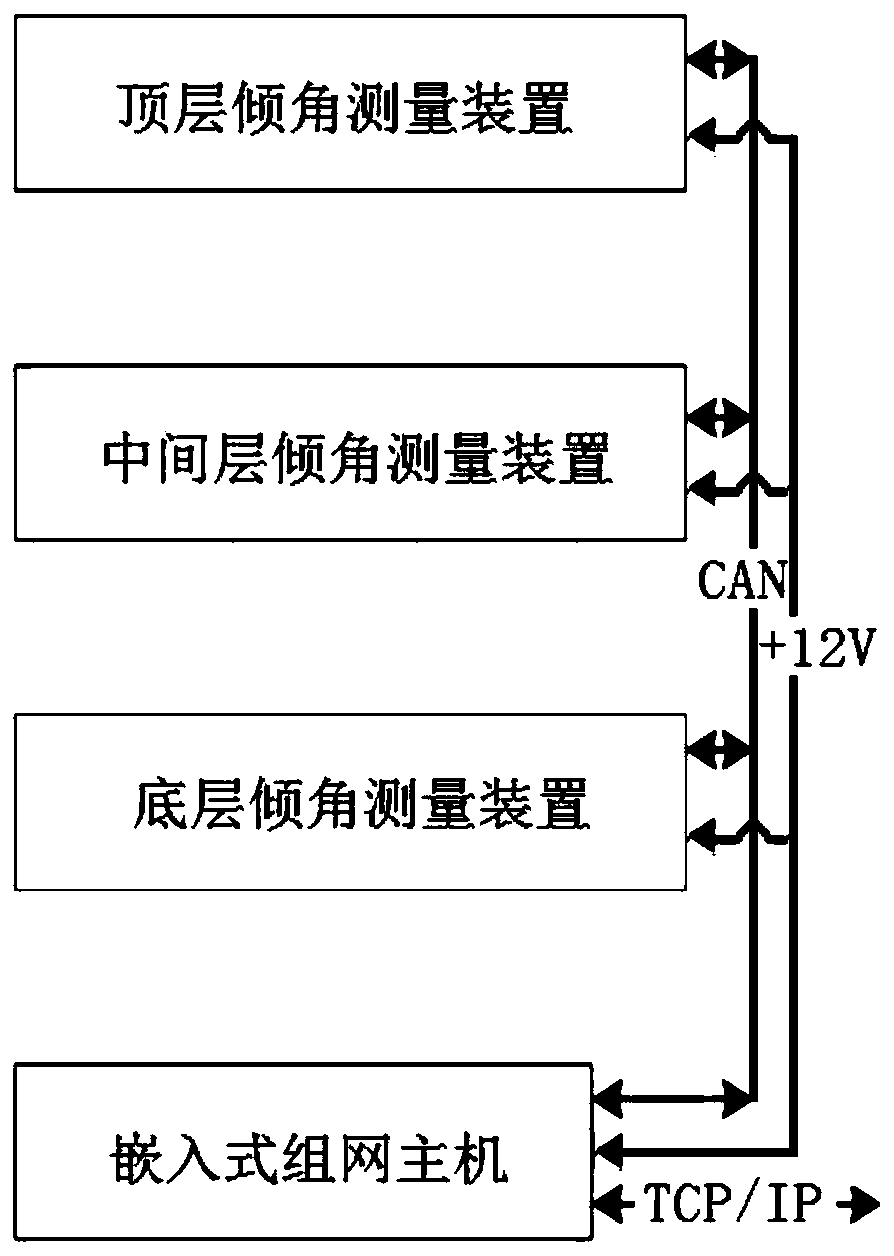

[0019] refer to figure 1 , Each tower detection system consists of more than 3 inclination measuring devices, an embedded networking host, auxiliary power supply, wiring harness and auxiliary installation mechanism.

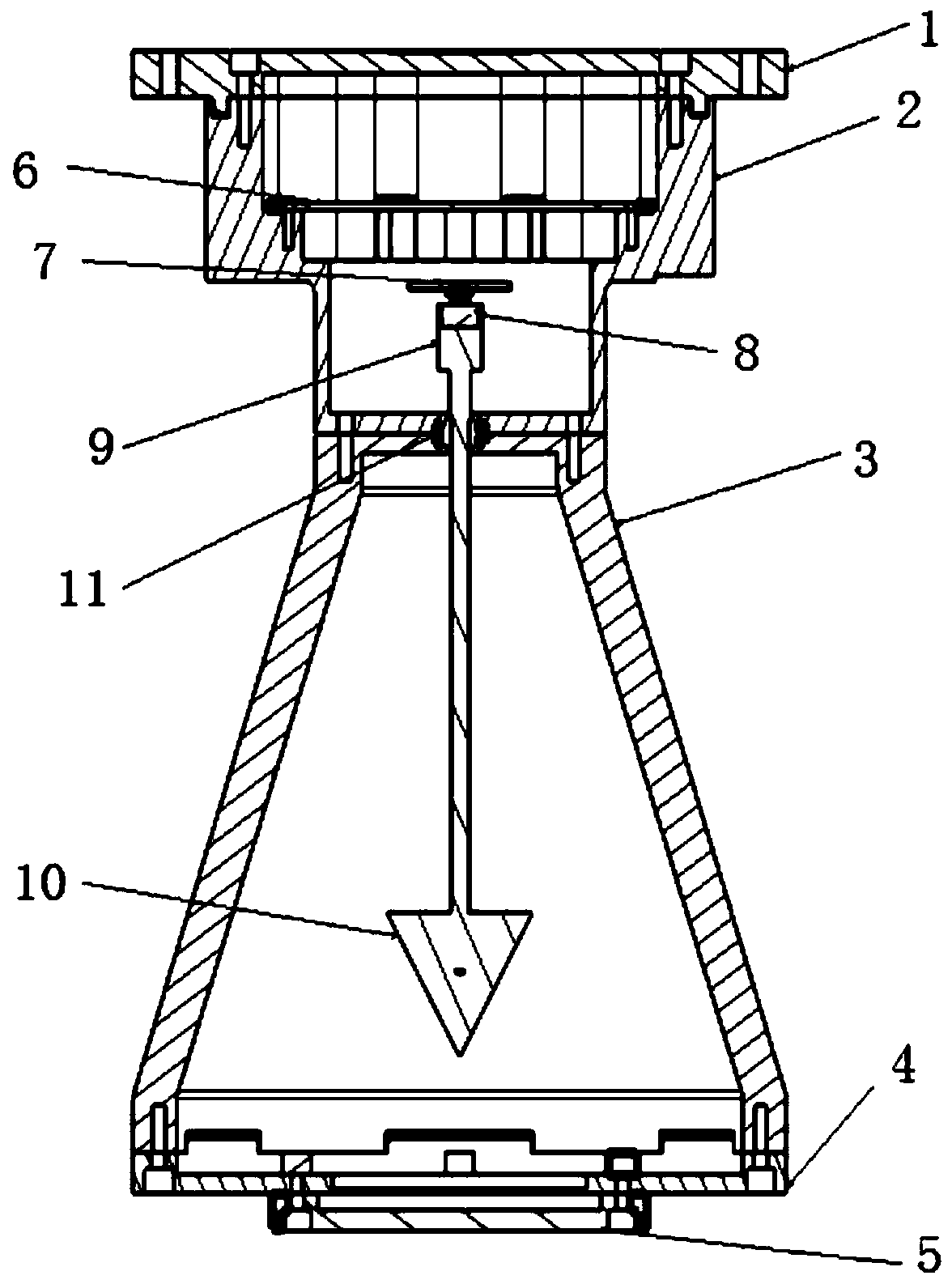

[0020] Inclination measuring device includes electronic part and unique mechanical structure. The three-dimensional Hall sensor inside the circuit part of the inclination measuring device is sensitive to the three magnetic flux densities (BX, BY and BZ) applied to the IC. The built-in microprocessor processes the data and communicates with the outside through the SPI bus to complete initialization and data transmission. and diagnosis.

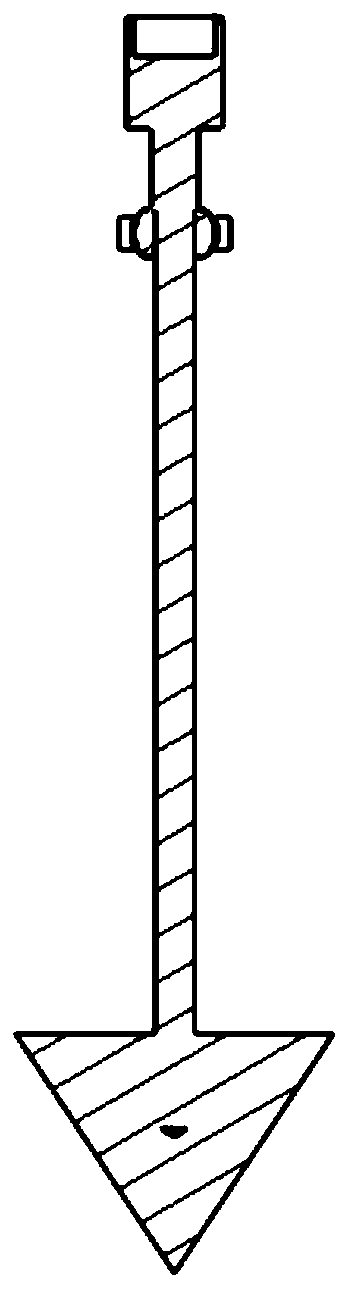

[0021] The actual operation of the wind power tower, due to the natural environment, naturally swings in real time. The swing posture is complex, and it is generally a twisted swing. Such real-time swing puts forward higher requirements on the mechanical performance of the measuring device. High sensitivity, but also to avoid fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com