Inverted Micro LED full-color quantum dot chip and preparation method and application thereof

A quantum dot and chip technology, applied in the field of LED chips, can solve the problem that a single LED chip cannot obtain full color effect, achieve the effect of huge transfer efficiency and yield, save wafer area, and save chip cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

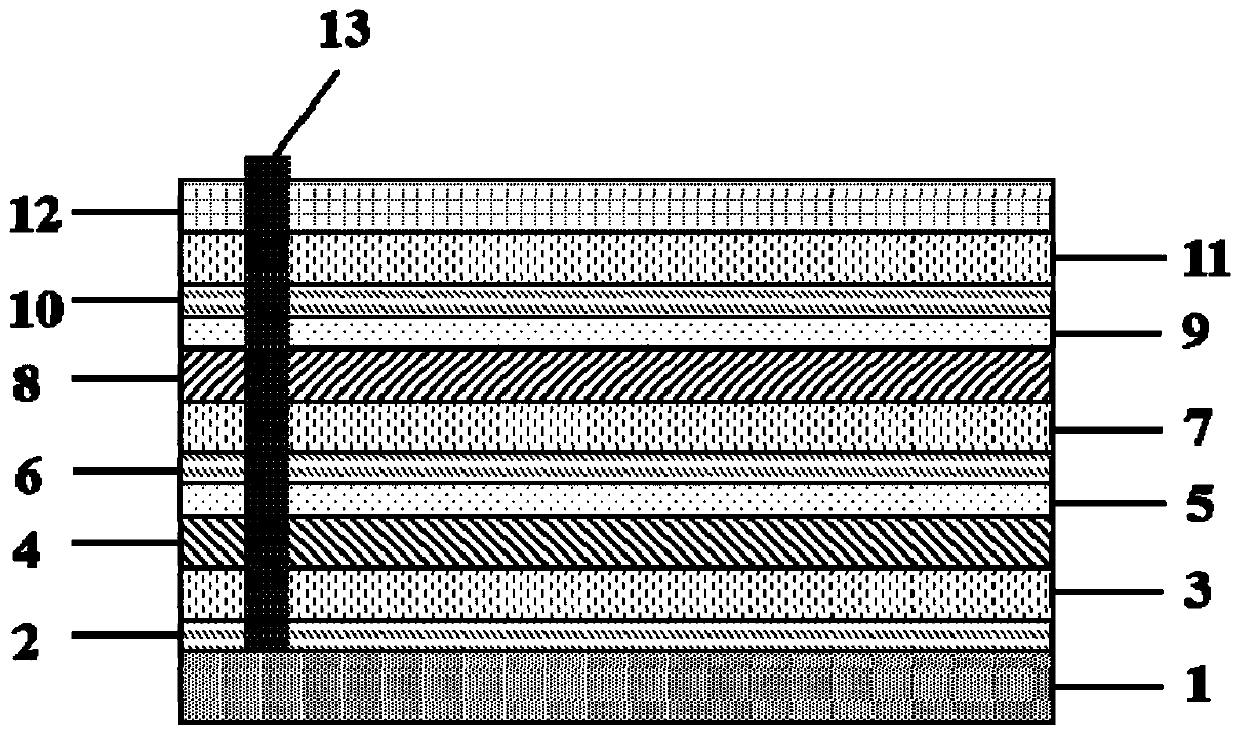

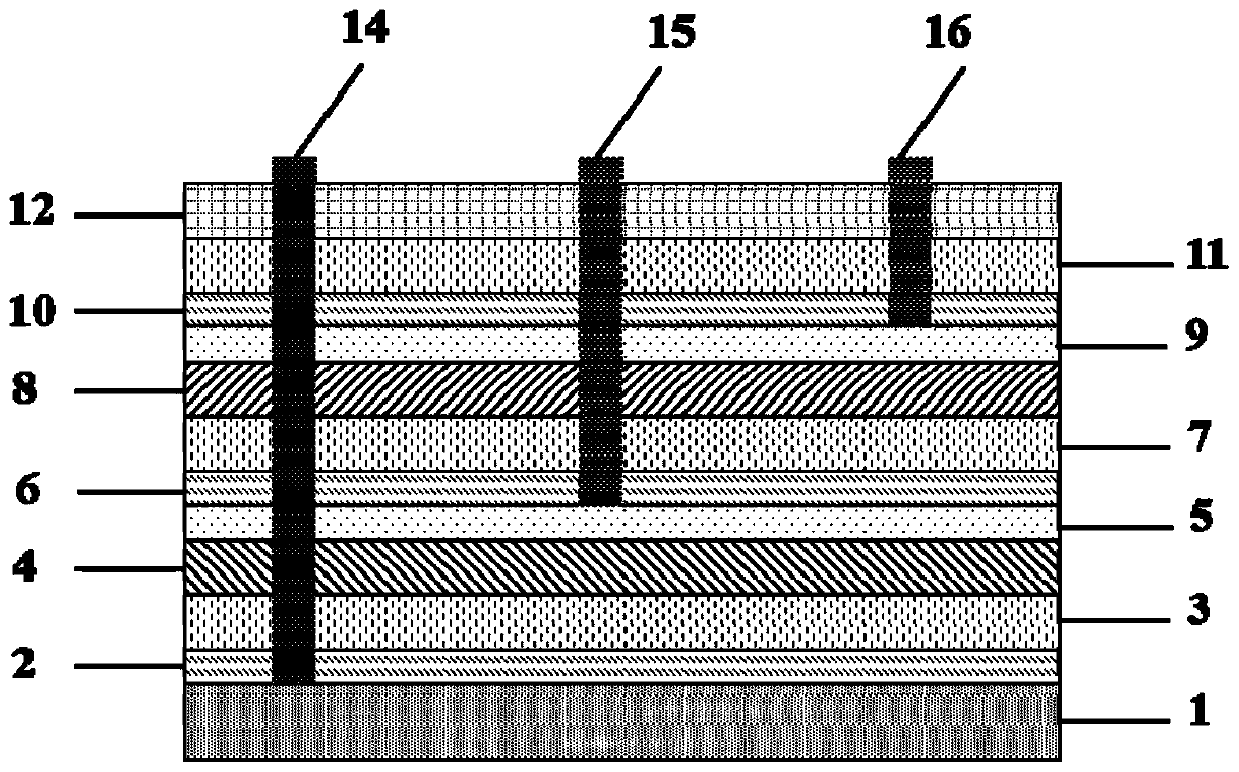

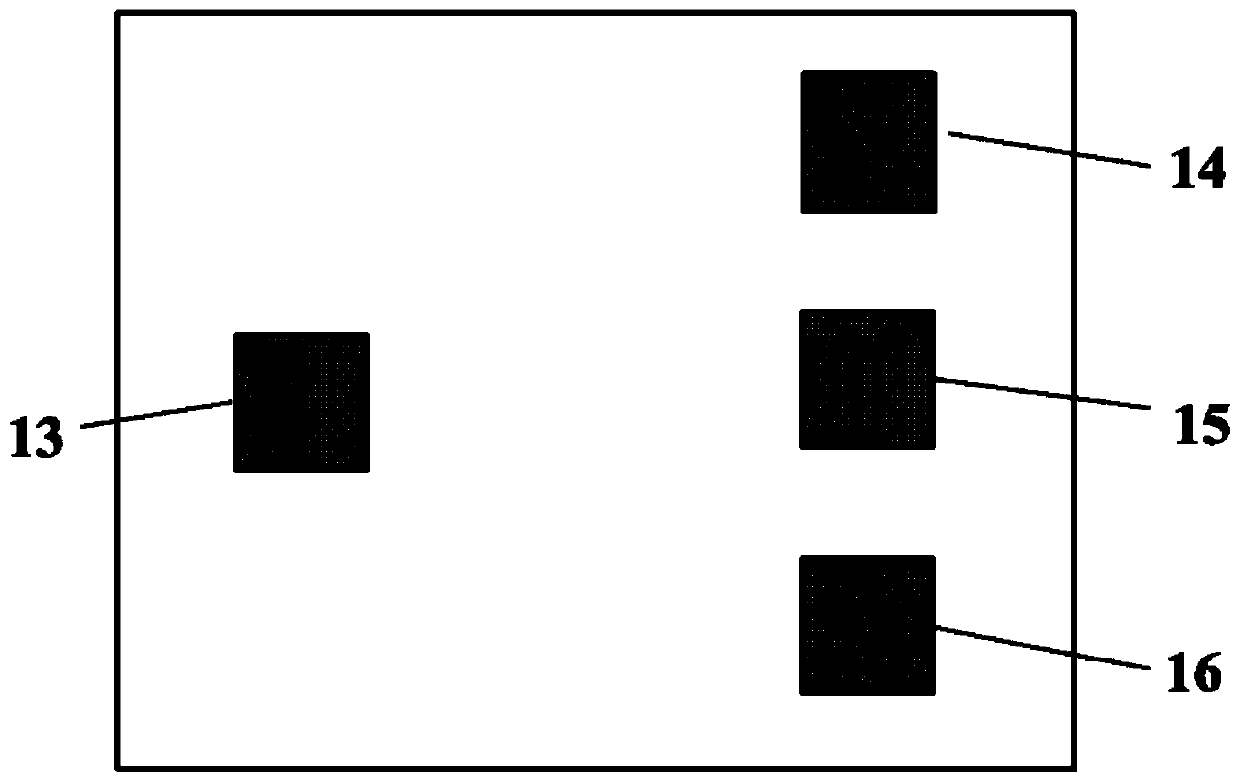

[0058] The front view of the flip-chip Micro LED full-color quantum dot chip structure in this embodiment is as follows figure 1 As shown, the left view is as figure 2 As shown, the top view is as image 3 As shown, it contains a substrate 1, a first blue light epitaxial layer 2, a first indium tin oxide layer 3, a first light-emitting quantum dot layer 4, a first transparent bonding material layer 5, a second blue light epitaxial layer 6, a second Indium tin oxide layer 7, second luminescent quantum dot layer 8, second transparent bonding material layer 9, third blue light epitaxial layer 10, third indium tin oxide layer 11, DBR reflective layer 12, fourth P electrode 13, fourth An N electrode 14 , a second N electrode 15 and a third N electrode 16 .

[0059] The substrate 1 described in this embodiment is a sapphire substrate with a thickness of 100 μm; the first blue light epitaxial layer 2 includes a blue light N-type gallium nitride layer with a thickness of 20 nm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com