A high temperature resistant antifreeze mpp pipe

An anti-freezing and high-temperature-resistant technology, which is applied to cable installation, cable installation, and electrical components in underground pipelines. It can solve problems such as pipe cracking, damage, and cable safety hazards, and achieve slowdown of extreme temperatures and heat accumulation. , to ensure the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

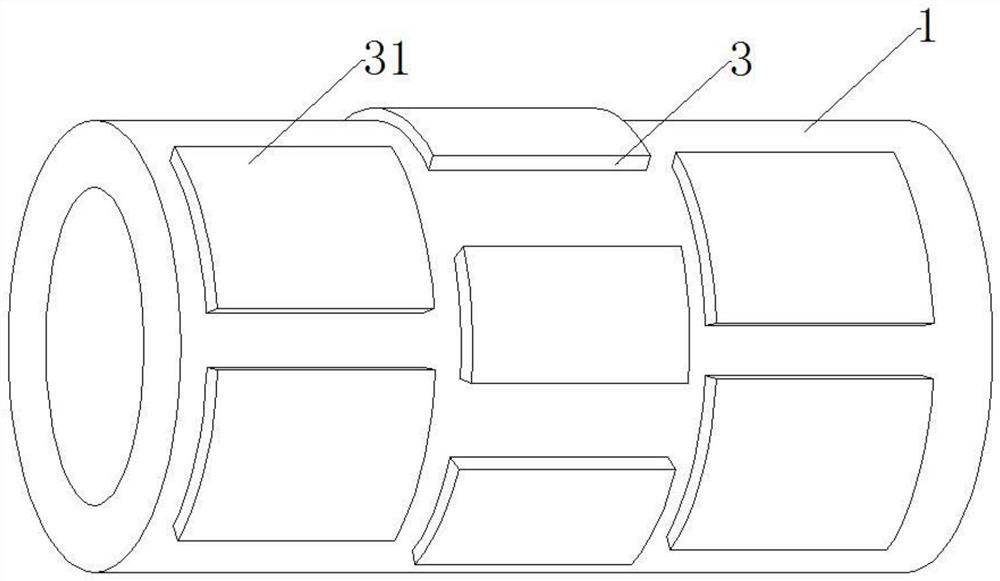

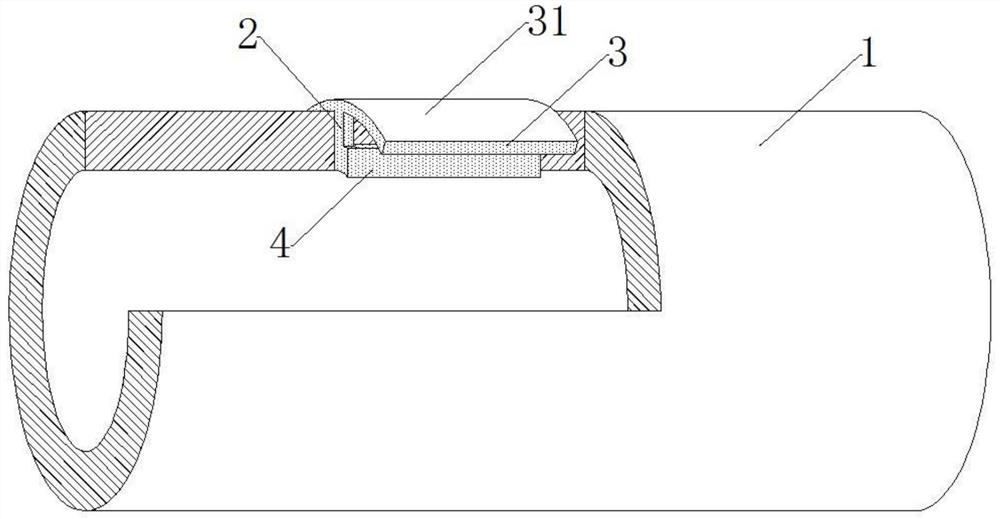

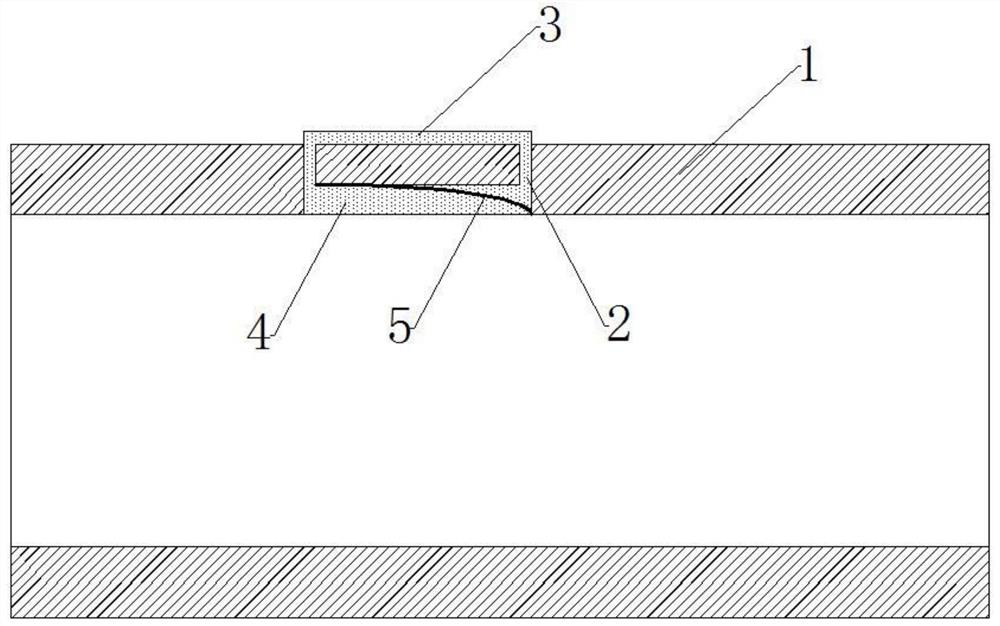

[0030] Example: see Figure 1 to Figure 5 , a high-temperature-resistant and anti-freezing MPP pipe, comprising a pipe body 1, on which a diversion channel is opened radially through the pipe wall along the pipe body 1, and a diversion channel is provided in the diversion channel Tube 2, the outer wall of the guide tube 2 and the inner wall of the guide channel are close to each other; in order to ensure the sealing and reliability of the tube body 1; a heat dissipation chamber 3 is set on the outer wall of the tube body 1, and the heat dissipation The surface of the chamber 3 in contact with the environment outside the pipe body 1 forms a heat dissipation surface 31; a heat-absorbing chamber 4 is arranged on the inner wall of the pipe body 1, and the surface of the heat-absorbing chamber 4 in contact with the environment inside the pipe body 1 forms a heat dissipation surface 31. The heat-absorbing surface 41; the cooling chamber 3 and the heat-absorbing chamber 4 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com