Variable stiffness software driver and hand rehabilitation training robot using the same

A soft driver and variable stiffness technology, applied in the field of medical rehabilitation robots, can solve the problems of hand rehabilitation and poor load capacity of stroke patients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

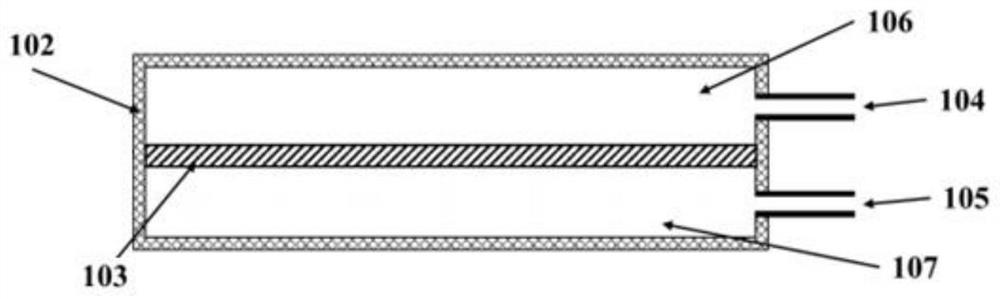

[0033] This embodiment provides a variable stiffness soft driver 111, such as Figure 1-5 As shown, it includes: a layered driver body, and an air cavity is arranged in the driver body; the surface layer of the layered driver body in this embodiment is set as a rectangular body formed by an elastically deformable cavity wall 102, and the air cavity is also is a rectangular cavity.

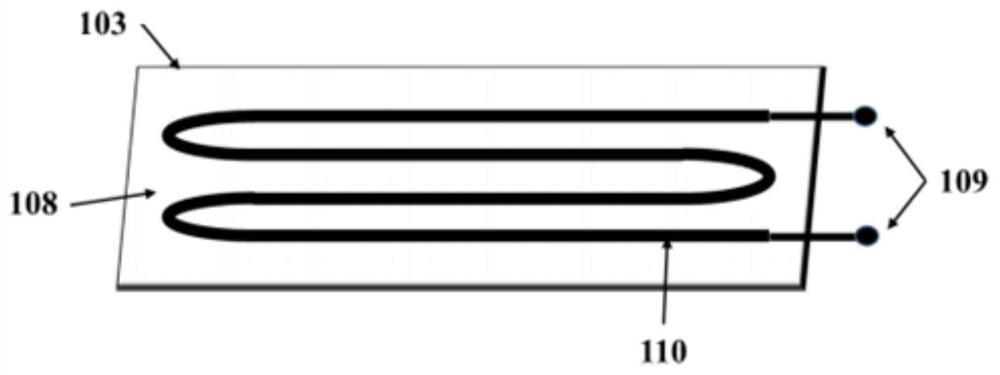

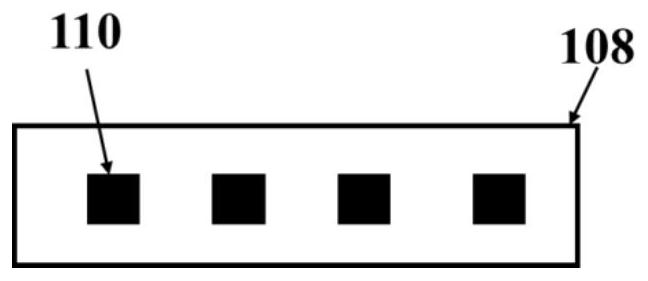

[0034]A variable stiffness layer 103 is provided at the middle position of the air cavity, and the air cavity is divided into an upper chamber 106 and a lower chamber 107; the variable stiffness layer 103 includes a flexible material layer 108, and the flexible material layer The tensile modulus of 108 is greater than the tensile modulus of the elastic deformation cavity wall 102 of the air cavity; the variable stiffness layer 103 in this embodiment includes a flexible material layer 108 and a low melting point alloy 110, and the low melting point alloy 110 is arranged in the serpentine flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com