Viscous hazardous waste disposal method

A technology for hazardous waste and disposal methods, applied in separation methods, chemical instruments and methods, solid waste removal, etc., can solve problems such as reducing equipment disposal efficiency, polluting soil and groundwater, reducing equipment resource utilization, etc., to achieve good environmental protection and economic benefits, increase production quality, and improve disposal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

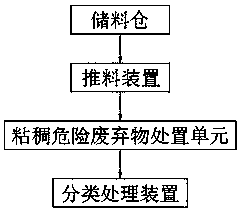

[0031] A viscous hazardous waste disposal method:

[0032] S1: Place the viscous hazardous waste that needs to be processed in the waste storage pool of the storage bin through the transport vehicle, and complete the transportation preparation of the viscous hazardous waste;

[0033] S2: Transport the viscous hazardous waste in the storage bin to the viscous hazardous waste disposal unit for pretreatment through the pushing device;

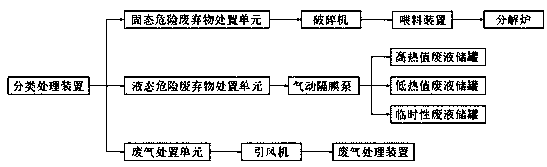

[0034] S3: The pretreated hazardous waste is connected to the classification treatment device for specific separation of hazardous waste, and the waste after separation of viscous hazardous waste enters the solid hazardous waste disposal unit and liquid hazardous waste disposal unit respectively and waste gas treatment unit for classified treatment;

[0035] S4: Hazardous waste in solid form enters the solid hazardous wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com