Aging device for automatic radar production line

An automatic production line and aging device technology, applied to conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of PCBA invisible damage, high production cost, low production efficiency, etc., to save length space and high production efficiency , the effect of reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

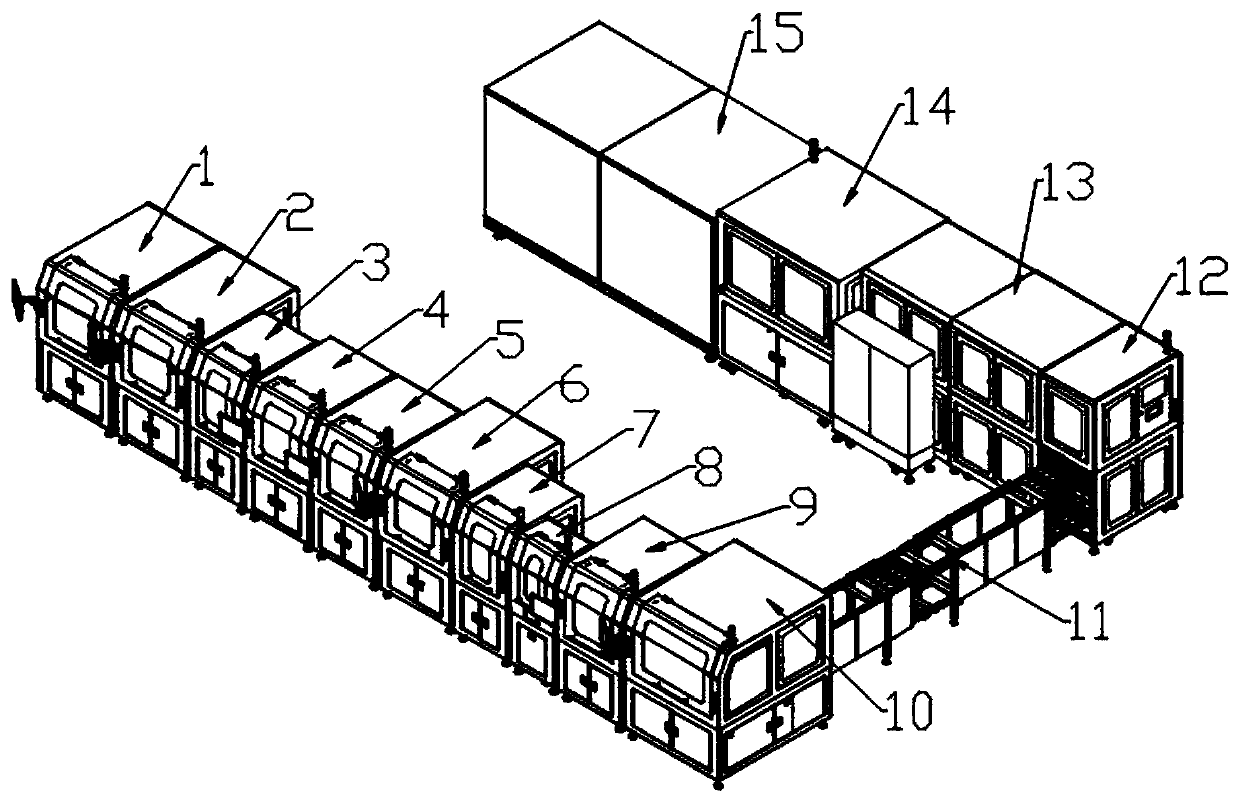

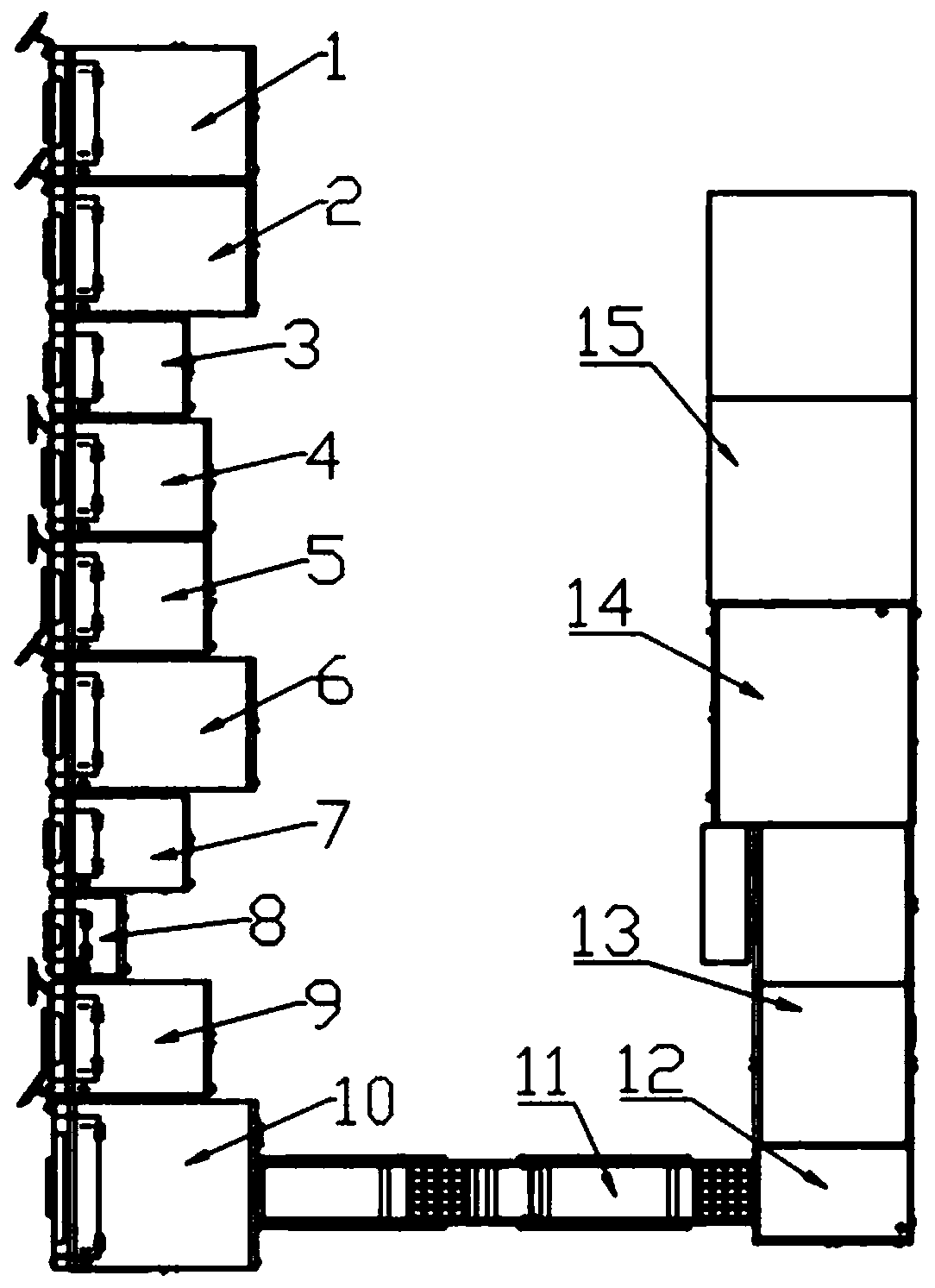

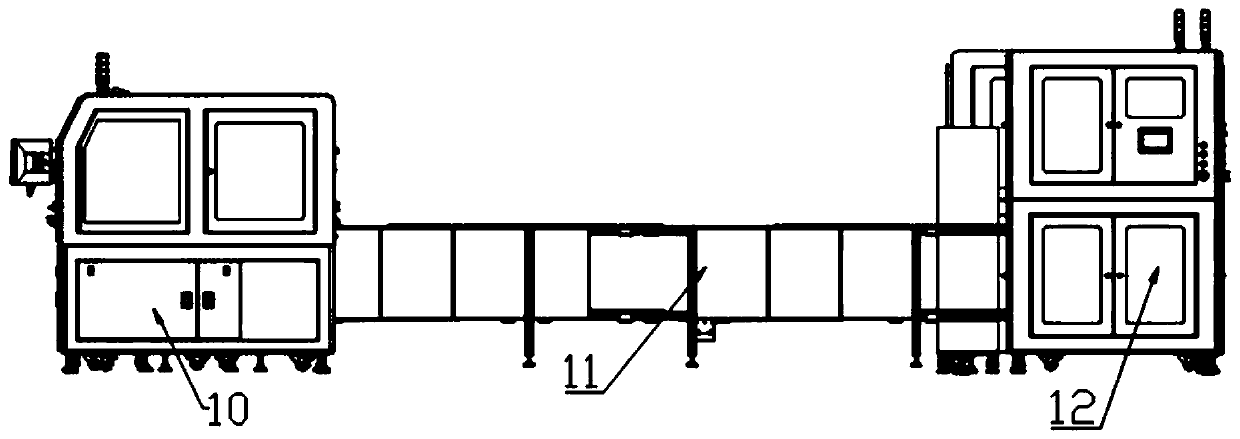

[0044] A millimeter-wave radar automated intelligent production line, as attached Figure 1~3 As shown, it includes 15 units in turn: cover plate feeding machine (1), PCBA plate feeding machine (2), PCBA board marking machine (3), PCBA board and cover plate assembly machine (4), heat conduction sheet machine (5), waterproof base feeding machine (6), waterproof base marking machine (7), pressure holding machine (8), waterproof base assembly machine (9), air tightness testing machine (10), double-layer transportation Belt conveyor (11), aging box feeder (12), aging box (13), finished product discharging machine (14), dark box test unit (15), the automatic intelligent production line of millimeter wave radar adopts U-shaped line Layout, the cover board feeder (1), PCBA board feeder (2), PCBA board marking machine (3), PCBA board and cover board assembly machine (4), heat conducting sheet paste machine (5), The waterproof base feeding machine (6), the waterproof base marking mach...

Embodiment 2

[0075] as attached Figure 22 As shown, the dark box test can also adopt the mode of off-line test to set up a dark box test room. Personnel enter and exchange radar products. The radar products are placed on the anechoic radar turntable module (16-2). The darkroom radar turntable module (16-2) is designed on the same principle as the radar turntable module (15-2). The darkroom radar turntable module (16-2) is installed on the turntable track (16-6), and the turntable track (16-6) is 0.5 to 1 meter long, and other parts of the darkroom linear slide rail (16-3), darkroom Arc-shaped slide rail (16-4), darkroom target simulator (16-5) and linear slide rail (15-3), darkroom arc-shaped slide rail (15-4), darkroom target simulator (15-5) The principle and structure are the same, and the anechoic chamber can simulate and test the performance of the radar in motion by setting the turntable track (16-6).

[0076] Other Alternative Embodiments

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com