Application of anti-blue light film, anti-blue light film and its preparation method and application

An anti-blue light and film technology, applied in the field of anti-blue light, can solve the problems of affecting product life, complex preparation process, secondary damage to human eyes, etc., and achieve the effect of avoiding secondary damage, good chemical stability, and maintaining color balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing the anti-blue light film described in the above scheme, comprising the following steps:

[0032] (1) Bi(NO 3 ) 3 ·5H 2 O, NH 4 VO 3 , citric acid and a solvent are mixed to obtain a mixed material liquid after the reaction;

[0033] (2) the mixture liquid is mixed with monoethanolamine, and the bismuth monoclinic vanadate precursor solution is obtained after the reaction;

[0034] (3) the monoclinic bismuth vanadate precursor solution is coated on the surface of one side of the glass cover plate, after being dried and annealed successively, the first film layer is formed on the surface of the glass cover plate side;

[0035] (4) The monoclinic bismuth vanadate precursor solution is coated on the surface of the other side of the glass cover plate, and after being dried and annealed successively, a second film layer is formed on the surface of the other side of the glass cover plate to obtain an anti- Blu-ray fil...

Embodiment 1

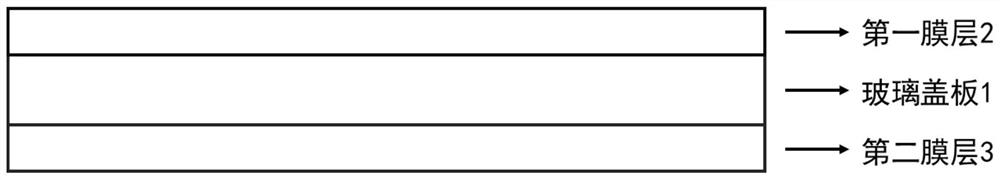

[0051] like figure 1 As shown, the anti-blue light film of this embodiment includes a glass cover plate 1, a first film layer 2 and a second film layer 3, and the first film layer 2 and the second film layer 3 are respectively deposited on both sides of the glass cover plate 1 .

[0052] The preparation method is as follows:

[0053] Bi(NO 3 ) 3 ·5H 2 O, NH 4 VO 3 Add citric acid and citric acid into a mixed solvent of acetic acid and DMF at a molar ratio of 1:1:4 (the volume ratio of acetic acid and DMF is 20:80), stir and react at 40°C for 2 hours, and obtain a sky blue mixed material liquid;

[0054] Slowly add monoethanolamine dropwise into the mixed material liquid, stir and react at 40°C for 12h, until the color of the solution turns dark blue-green, add the mixed solvent of acetic acid and DMF to the above solution (wherein, for the first film layer 2, supplemented The volume ratio of acetic acid and DMF in the mixed solvent is 10:90; For the second film layer 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com