Preparation method of low-sugar grains

A technology of grain and preparation steps, which is applied in the field of preparation of low-sugar grains, can solve the problems of loss of residual nutrients, reduction of sugar content, and lack of essential trace elements, etc., and achieves the effects of convenient production and preparation, convenient classification and processing, and food saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

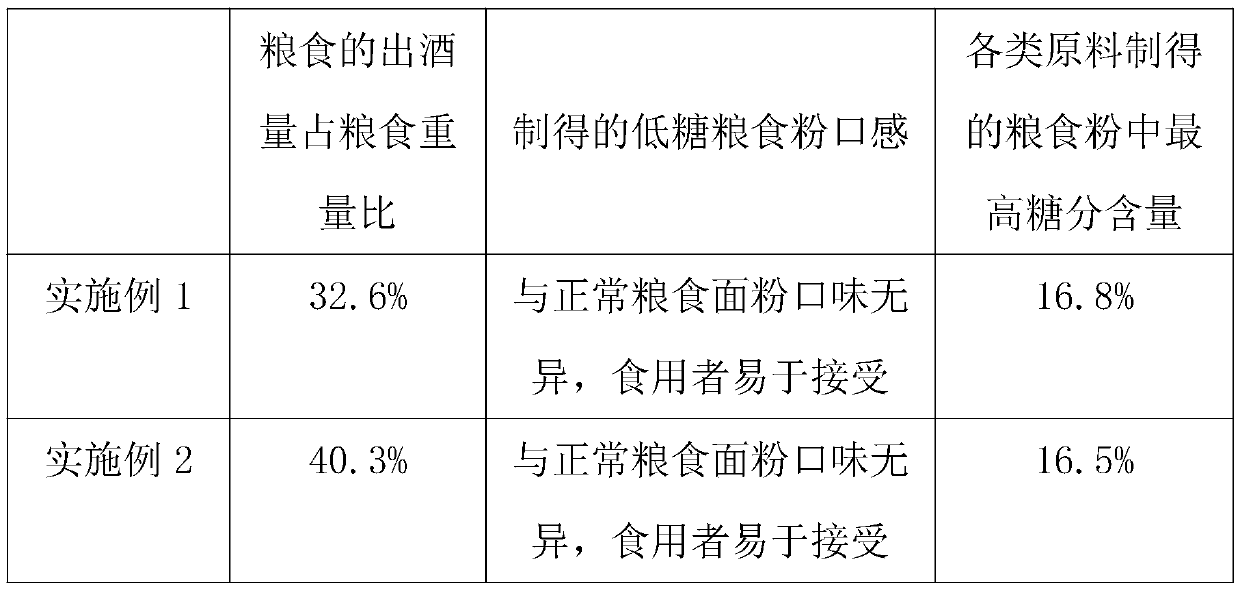

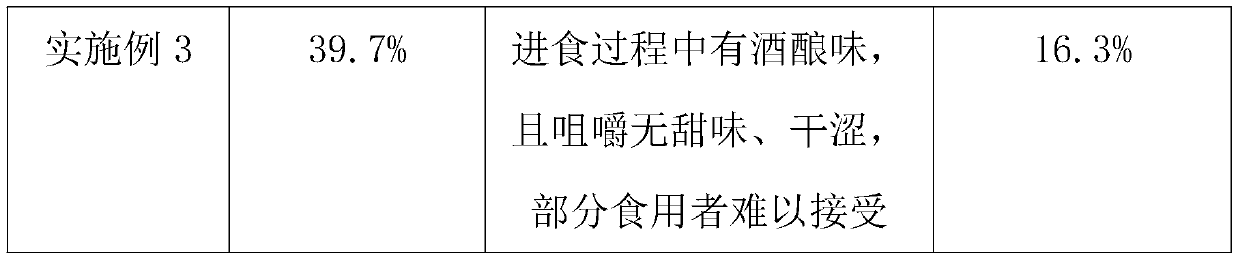

Embodiment 1

[0025] The invention provides a method for preparing low-sugar grains, the specific preparation steps are as follows:

[0026] a) Shelling of raw materials: Wash and remove impurities from any one or combination of prepared rice, sorghum, millet, corn, soybeans, peas, corn, barley and wheat, and then dry them for later use. According to the feed-to-feed ratio of the factory's production specifications, the various grains required are weighed and shelled according to the per unit yield;

[0027] b) Cooking of raw materials: each dehulled grain obtained in step a) is steamed separately according to wine making requirements: soaking grain, initial steaming, stewing in water, re-steaming, and the step of soaking grain needs to ensure that the shelled grain is on the soaking water surface 20-25cm, and the soaking time is not less than 10h; the initial steaming step needs to be kept loose, and the air permeability is better, and the initial steaming time is controlled at 15-30min af...

Embodiment 2

[0034] The invention provides a method for preparing low-sugar grains, the specific preparation steps are as follows:

[0035] a) Shelling of raw materials: Wash and remove impurities from any one or combination of prepared rice, sorghum, millet, corn, soybeans, peas, corn, barley and wheat, and then dry them for later use. According to the feed-to-feed ratio of the factory's production specifications, the various grains required are weighed and shelled according to the per unit yield;

[0036] b) Cooking of raw materials: each dehulled grain obtained in step a) is steamed separately according to wine making requirements: soaking grain, initial steaming, stewing in water, re-steaming, and the step of soaking grain needs to ensure that the shelled grain is on the soaking water surface 20-25cm, and the soaking time is not less than 10h; the initial steaming step needs to be kept loose, and the air permeability is better, and the initial steaming time is controlled at 15-30min af...

Embodiment 3

[0044] The invention provides a method for preparing low-sugar grains, the specific preparation steps are as follows:

[0045] a) Shelling of raw materials: Wash and remove impurities from any one or combination of prepared rice, sorghum, millet, corn, soybeans, peas, corn, barley and wheat, and then dry them for later use. According to the feed-to-feed ratio of the factory's production specifications, the various grains required are weighed and shelled according to the per unit yield;

[0046] b) Cooking of raw materials: each dehulled grain obtained in step a) is steamed separately according to wine making requirements: soaking grain, initial steaming, stewing in water, re-steaming, and the step of soaking grain needs to ensure that the shelled grain is on the soaking water surface 20-25cm, and the soaking time is not less than 10h; the initial steaming step needs to be kept loose, and the air permeability is better, and the initial steaming time is controlled at 15-30min af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com