Black wine and making method thereof

A black wine and black bean technology, applied in the field of black wine and its preparation, can solve the problems of long growth cycle, unstable quality, long processing time, etc., achieve clear liquor, shorten production time, improve drinkability and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

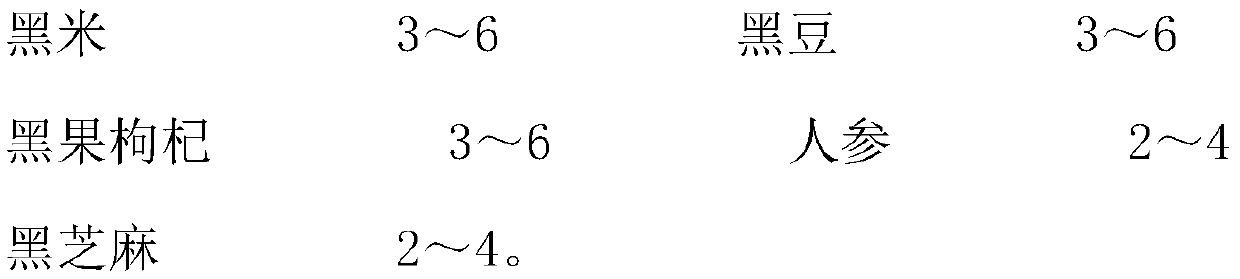

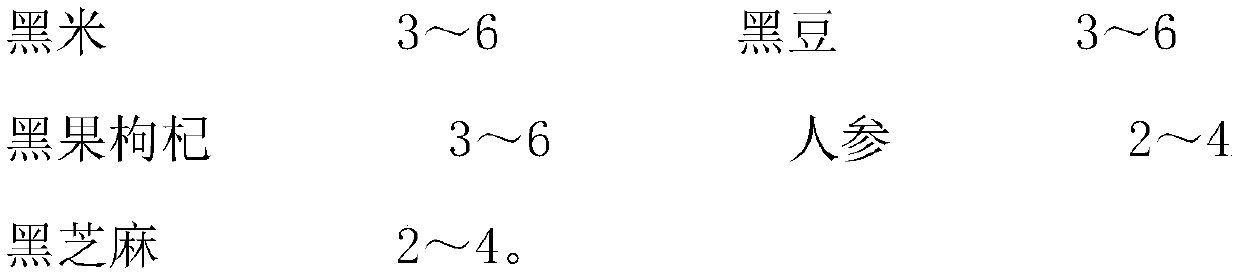

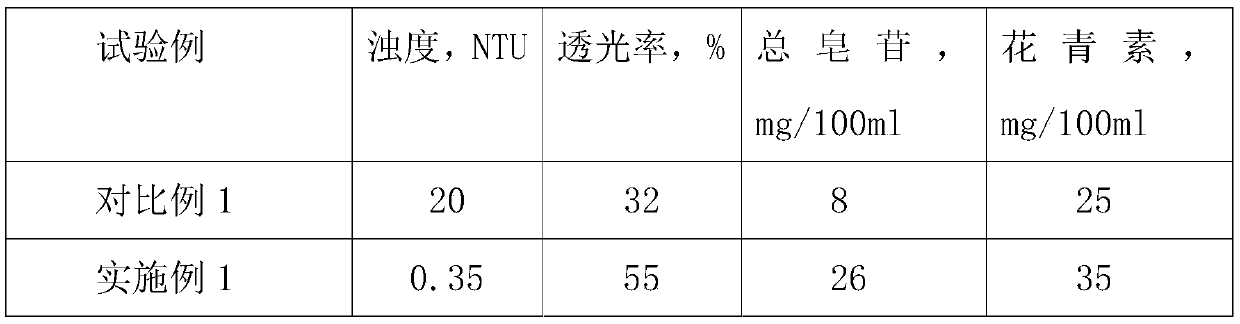

[0035] 1. Selection and processing of raw materials: A total of 21.6kg of raw materials were selected that meet the company's quality requirements, including 5.4kg of black rice, 5.4kg of black beans, 5.4kg of black wolfberry, 2.7kg of ginseng, and 2.7kg of black sesame. Ginseng must be sliced before use.

[0036] 2. Extraction: Put 21.6kg of raw materials into the extraction tank, extract the raw materials with 50% vol edible alcohol for 3 times, add 7 times the amount of 50% vol edible alcohol solution respectively, the extraction time is 1.5 hours / time, and the extraction temperature is 75°C. Extract three times and combine the extracts to obtain 408 L of extracts.

[0037] 3. Purification: The extract is filtered, and the filtered liquid is treated with a 0.10μm ceramic membrane device, and the temperature is controlled at 48°C during the filtration process.

[0038] 4. Concentration: Transfer the membrane filtrate to a single-effect concentrator, and concentrate under r...

Embodiment 2

[0042] 1. Selection and processing of raw materials: A total of 20.8kg of raw materials are selected that meet the quality requirements of the company, including 5.2kg of black rice, 5.2kg of black beans, 5.2kg of black wolfberry, 2.6Kg of ginseng, and 2.6kg of black sesame. Ginseng must be sliced before use.

[0043] 2. Extraction: Put 20.8kg of raw materials into the extraction tank, extract the raw materials with 50% vol edible alcohol for 3 times, add 7 times the amount of 50% vol edible alcohol solution respectively, the extraction time is 1.5 hours / time, and the extraction temperature is 75°C. Extract three times and combine the extracts to obtain 392L of extracts.

[0044] 3. Purification: The extract is filtered, and the filtered liquid is treated with a 0.10μm ceramic membrane device, and the temperature is controlled at 48°C during the filtration process.

[0045] 4. Concentration: Transfer the membrane filtrate to a single-effect concentrator, and concentrate under ...

Embodiment 3

[0049] 1. Selection and processing of raw materials: A total of 20.0kg of raw materials that meet the company's quality requirements are selected, including 5.0kg of black rice, 5.0kg of black beans, 5.0kg of black wolfberry, 2.5kg of ginseng, and 2.5kg of black sesame. Ginseng must be sliced before use.

[0050] 2. Extraction: Put 20.0kg of raw materials into the extraction tank, extract the raw materials with 50% vol edible alcohol for 3 times, add 7 times the amount of 50% vol edible alcohol solution respectively, the extraction time is 1.5 hours / time, and the extraction temperature is 75°C. Extract three times and combine the extracts to obtain 379L of extracts.

[0051] 3. Purification: The extract is filtered, and the filtered liquid is treated with a 0.10μm ceramic membrane device, and the temperature is controlled at 48°C during the filtration process.

[0052] 4. Concentration: Transfer the membrane filtrate to a single-effect concentrator, and concentrate under red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com