Steel substrate for producing a thermoformed and press-hardened steel sheet component and thermoforming method

A technology of thermoforming and matrix, applied in the field of steel matrix and thermoforming for manufacturing thermoformed and pressure-hardened steel plate members, which can solve problems such as roll cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

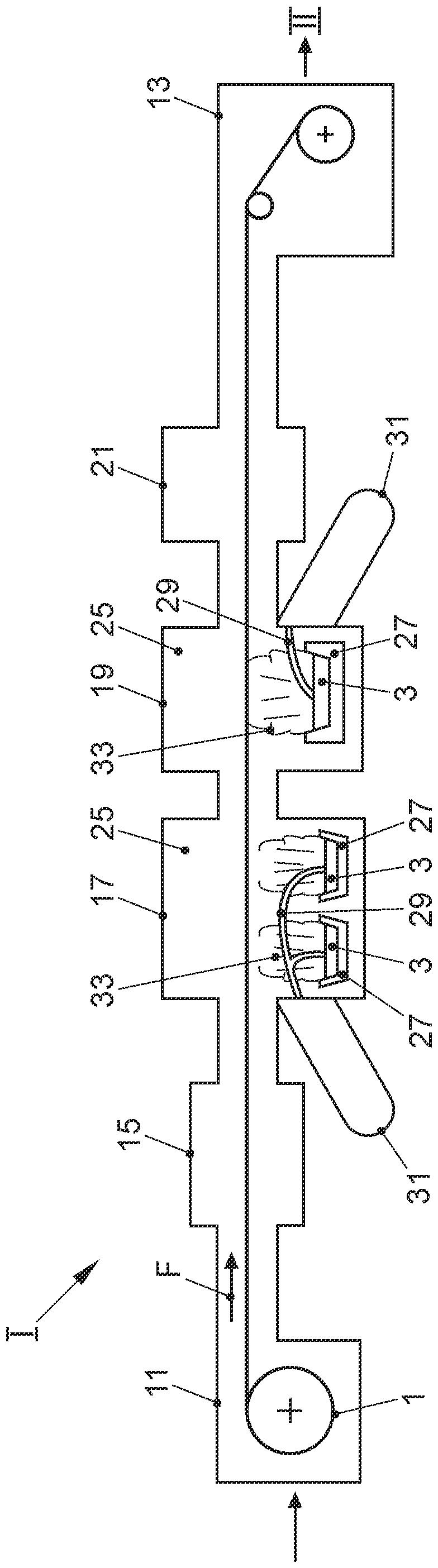

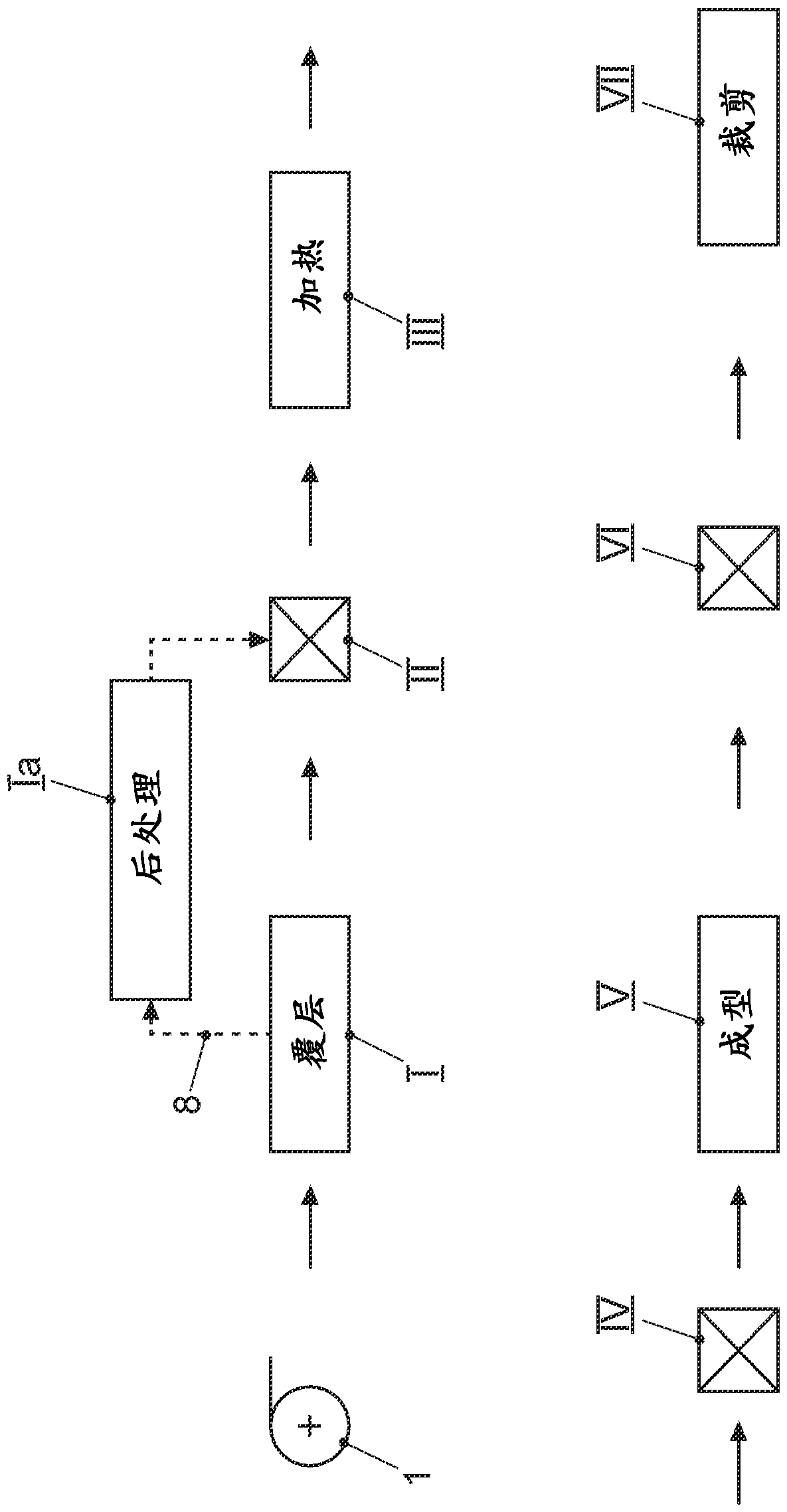

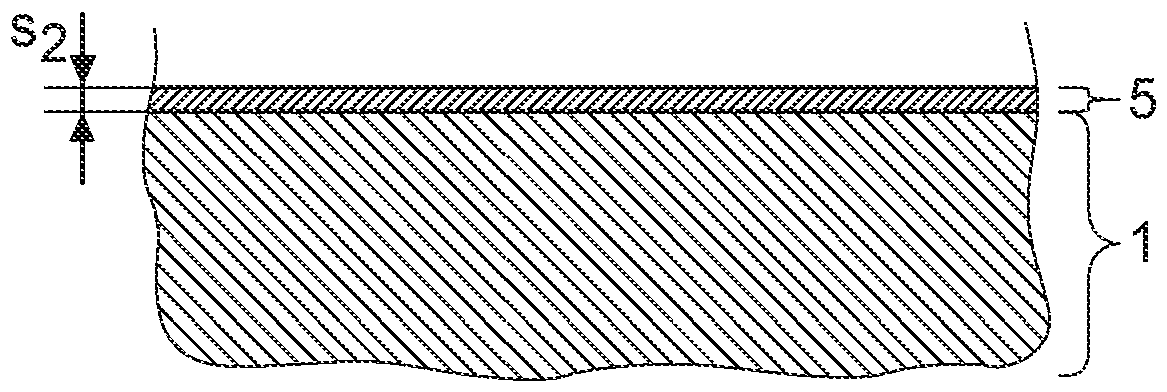

[0054] Next according to figure 1 The basic process sequence or process route for producing a hot-formed and press-hardened steel sheet part will be explained. The as yet uncoated steel matrix 1 is thus provided as rolled-up strip material (coil). The rolled strip material 1 is subjected to PVD coating step I, after which according to figure 2 to elaborate. PVD cladding is carried out in PVD cladding step I, wherein cladding material 3 ( figure 2 ) in physical gas phase separation (PVD) as PVD thin layer 5 ( Figure 4 ) is vaporized and evaporated onto the steel substrate 1 . The cutting step II follows, in which the now coated strip-shaped material 1 is cut into slabs in the cutting station II. The slab is then fed to the actual thermoforming process, which figure 1 are represented by process steps III to VII. The slab coated with the thin PVD layer 5 is therefore heat-treated in heat treatment step III, for example in a roller hearth furnace, above the austenitizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com