Preparation method of hydrophilic softener for cotton with good compatibility

A compatibility and softener technology, applied in the field of softener production, can solve problems such as production trouble and contamination, and achieve the effect of meeting the needs of use, excellent hydrophilicity and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

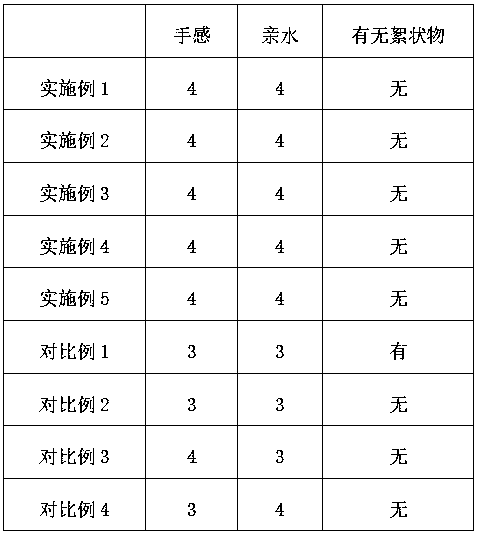

Examples

manufacture example 1

[0021] Preparation of Silicone Emulsion:

[0022] Take 2.5 grams of HD-104 (N-cyclohexyl-γ-aminopropylmethyldimethoxysilane) and add 0.25 grams of water, take 1.5 grams of GP-108 (3-piperazinylpropylmethyldimethoxy Silane) was added with 0.15 g of water, stirred evenly, and hydrolyzed for 20 minutes. Take 100g of D4 (octamethylcyclotetrasiloxane), 3g of ethyl cellulose, mix in the hydrolyzed HD-104 and GP-108, stir and heat up to 60-70°C, add 0.02g of lithium hydroxide, and continue to heat up To 120-130 ℃, heat preservation reaction for 3-4 hours, vacuumize to remove low molecular substances, and then lower the temperature to obtain amino silicone oil.

[0023] Take 20 grams of the self-made amino silicone oil obtained above, add 3.6 grams of XP-30, 4.4 grams of XP-70, and 2 g of hydroxyethylethylenediamine, and stir well; divide 72 grams of deionized water mixed with glacial acetic acid into several times After adding a small amount of water each time, stir at a high speed...

manufacture example 2

[0025] Basically the same as Production Example 1, except that ethyl cellulose was not added.

manufacture example 3

[0027] Basically the same as Production Example 1, except that hydroxyethylethylenediamine was not added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com