Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of complex production process of silicon-based solar cells, further improvement in stability, and constraints on development, so as to improve photoelectric conversion efficiency, facilitate electrical testing, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

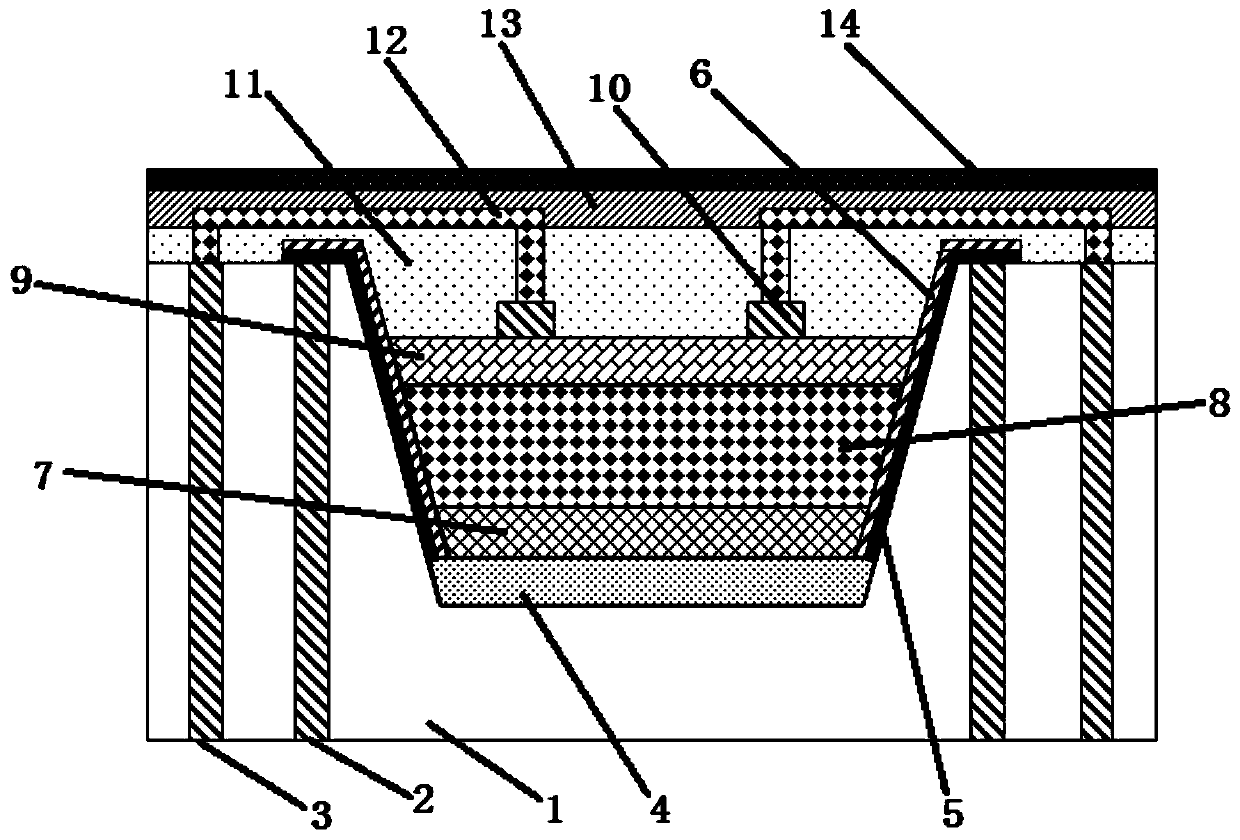

[0019] A method for preparing a perovskite solar cell, comprising the following steps: 1) providing a transparent substrate, forming a groove on the upper surface of the transparent substrate, and forming a plurality of first through holes and A plurality of second through holes, wherein the groove has a bottom surface and four sides, the angles between the first and third side surfaces and the bottom surface are both 120°-150°, and the second , the angle between the fourth side surface and the bottom surface is 90°; 2) then deposit a conductive material in the first through hole and the second through hole to form a first conductive via hole and a second conductive via hole respectively, and then A transparent conductive layer that completely covers the bottom surface of the groove is formed on the upper surface of the transparent substrate, and a plurality of metal strips are formed on the first and third side surfaces, and each metal strip is connected to the transparent con...

Embodiment 1

[0024] A method for preparing a perovskite solar cell, comprising the following steps: 1) providing a transparent substrate, forming a groove on the upper surface of the transparent substrate, and forming a plurality of first through holes and A plurality of second through holes, wherein the groove has a bottom surface and four side surfaces, the angles between the first and third side surfaces and the bottom surface are 150°, and the second and fourth sides are oppositely arranged The included angle between the side surface and the bottom surface is 90°; 2) then deposit a conductive material in the first through hole and the second through hole to form a first conductive via hole and a second conductive via hole respectively, and then A transparent conductive layer is formed on the upper surface of the transparent substrate to completely cover the bottom surface of the groove, and a plurality of metal strips are formed on the first and third side surfaces, each metal strip is ...

Embodiment 2

[0029] A method for preparing a perovskite solar cell, comprising the following steps: 1) providing a transparent substrate, forming a groove on the upper surface of the transparent substrate, and forming a plurality of first through holes and A plurality of second through holes, wherein the groove has a bottom surface and four side surfaces, the angles between the first and third side surfaces and the bottom surface are 120°, and the second and fourth sides are oppositely arranged The included angle between the side surface and the bottom surface is 90°; 2) then deposit a conductive material in the first through hole and the second through hole to form a first conductive via hole and a second conductive via hole respectively, and then A transparent conductive layer is formed on the upper surface of the transparent substrate to completely cover the bottom surface of the groove, and a plurality of metal strips are formed on the first and third side surfaces, each metal strip is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap