Metal foil, preparation method thereof, battery cell packaging method and battery module

A battery module and battery cell packaging technology, which is applied in the field of metal foil and battery modules, can solve the problems of inability to improve the sealing and safety of battery cells, and achieve easy mass production, high electrolyte resistance, and high viscosity. The effect of knot force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

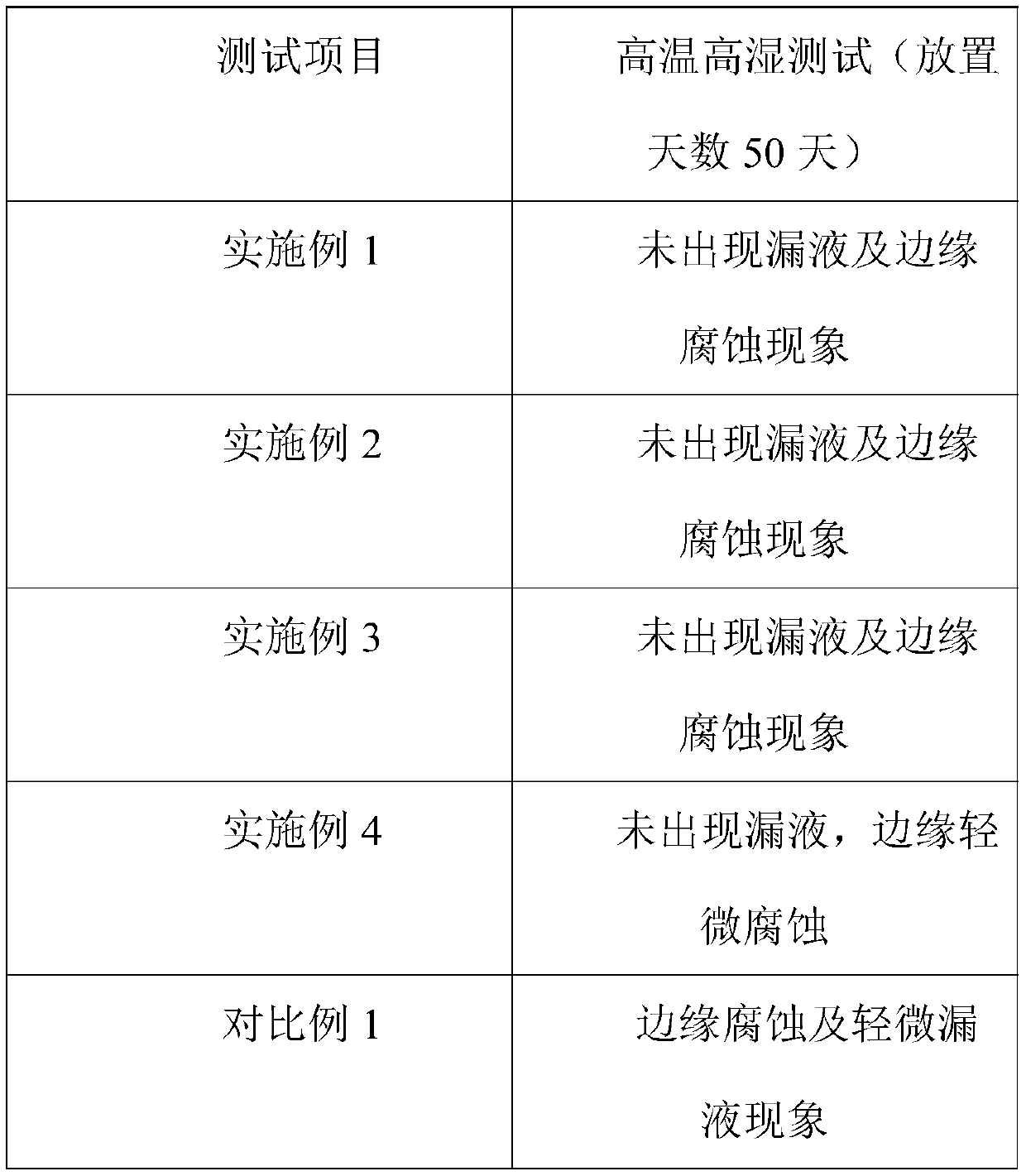

Embodiment 1

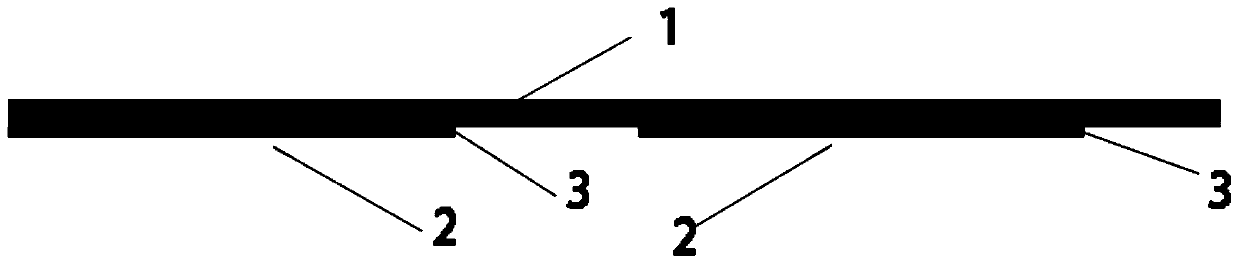

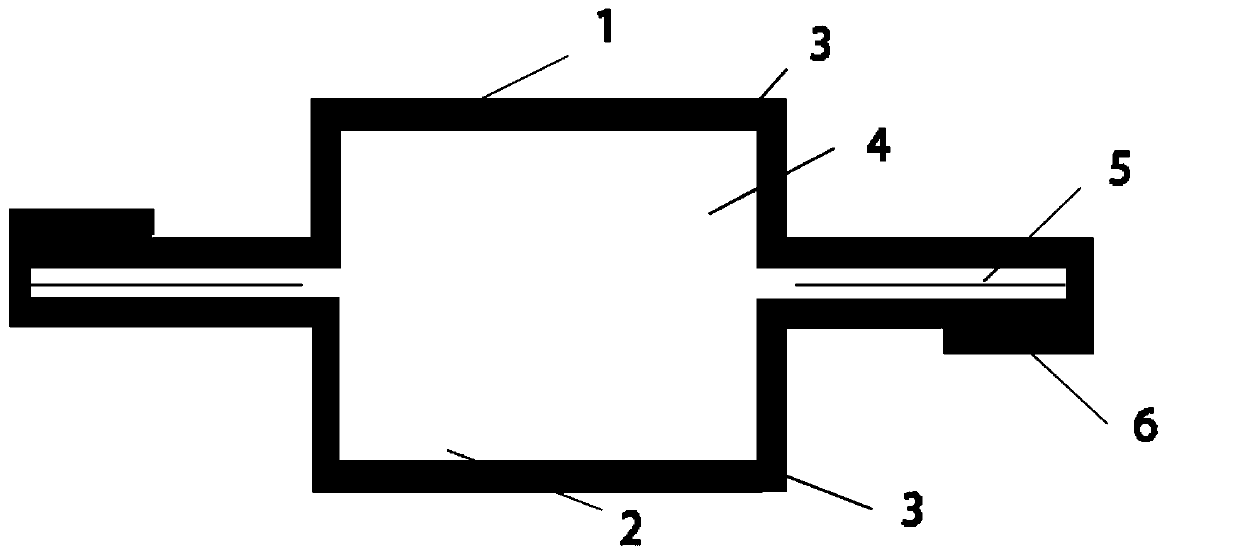

[0067] This embodiment provides a metal foil, the structure diagram of the metal foil is as follows figure 1 , including a base metal material 1, an adhesive layer 3 on the base metal material, and a heat-sealing material layer 2 on the adhesive. The base metal material 1 is steel foil; the adhesive layer 3 is composed of an adhesive, the adhesive is maleic acid-modified polypropylene, and the heat-sealing material of the heat-sealing material layer 2 is polypropylene (PP).

[0068] In the metal foil provided in this embodiment, the thickness of the adhesive layer 3 is 3 μm, and the thickness of the heat-sealing material layer is 65 μm. On the metal foil provided by the present invention, a blank with a width of 6mm is left on the edge (that is, the adhesive layer 3 and the heat-sealing material layer 2 are not included), and the base metal material 1 is provided with a gap with a size of 7mm (there is no gap on the gap). Contains an adhesive layer 3 and a heat-sealing materi...

Embodiment 2

[0077] This embodiment provides a metal foil. The structure of the metal foil refers to Embodiment 1, except that the adhesive is maleic acid-modified polypropylene. The thickness of the adhesive layer 3 is 1 μm, and the thickness of the heat-sealing material layer is 60 μm. On the metal foil provided by the present invention, there is a blank space with a width of 3mm on the edge (that is, without the adhesive layer 3 and the heat-sealing material layer 2), and the base metal material 1 is provided with a gap with a size of 3mm (there is no gap on the gap). Contains an adhesive layer 3 and a heat-sealing material layer 2).

[0078] This embodiment also provides a method of using the metal foil provided by this embodiment for cell packaging, specifically:

[0079] (1) Punch the metal foil provided in this embodiment, take one piece of the metal foil that has been punched and compound it with another piece of the metal foil that has not been punched, and place the battery cell...

Embodiment 3

[0083] This embodiment provides a metal foil. The structure of the metal foil refers to Embodiment 1, except that the adhesive is maleic acid-modified polypropylene. The thickness of the adhesive layer 3 is 5 μm, and the thickness of the heat-sealing material layer is 70 μm. On the metal foil provided by the present invention, there is a blank with a width of 10mm on the edge (that is, without the adhesive layer 3 and the heat-sealing material layer 2), and the base metal material 1 is provided with a gap with a size of 10mm (there is no gap on the gap). Contains an adhesive layer 3 and a heat-sealing material layer 2).

[0084] This embodiment also provides a method of using the metal foil provided by this embodiment for cell packaging, specifically:

[0085] (1) Punch the metal foil provided in this example, take 2 pieces of the metal foil that have been punched and combine them up and down, place the battery cell in the pit body of the 2 pieces of the metal foil that have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com