Rapid coconut peeling device

A fast, coconut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unsightly peeling, low peeling efficiency, low manual peeling efficiency, etc., to speed up peeling efficiency and reduce labor. Powerful, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

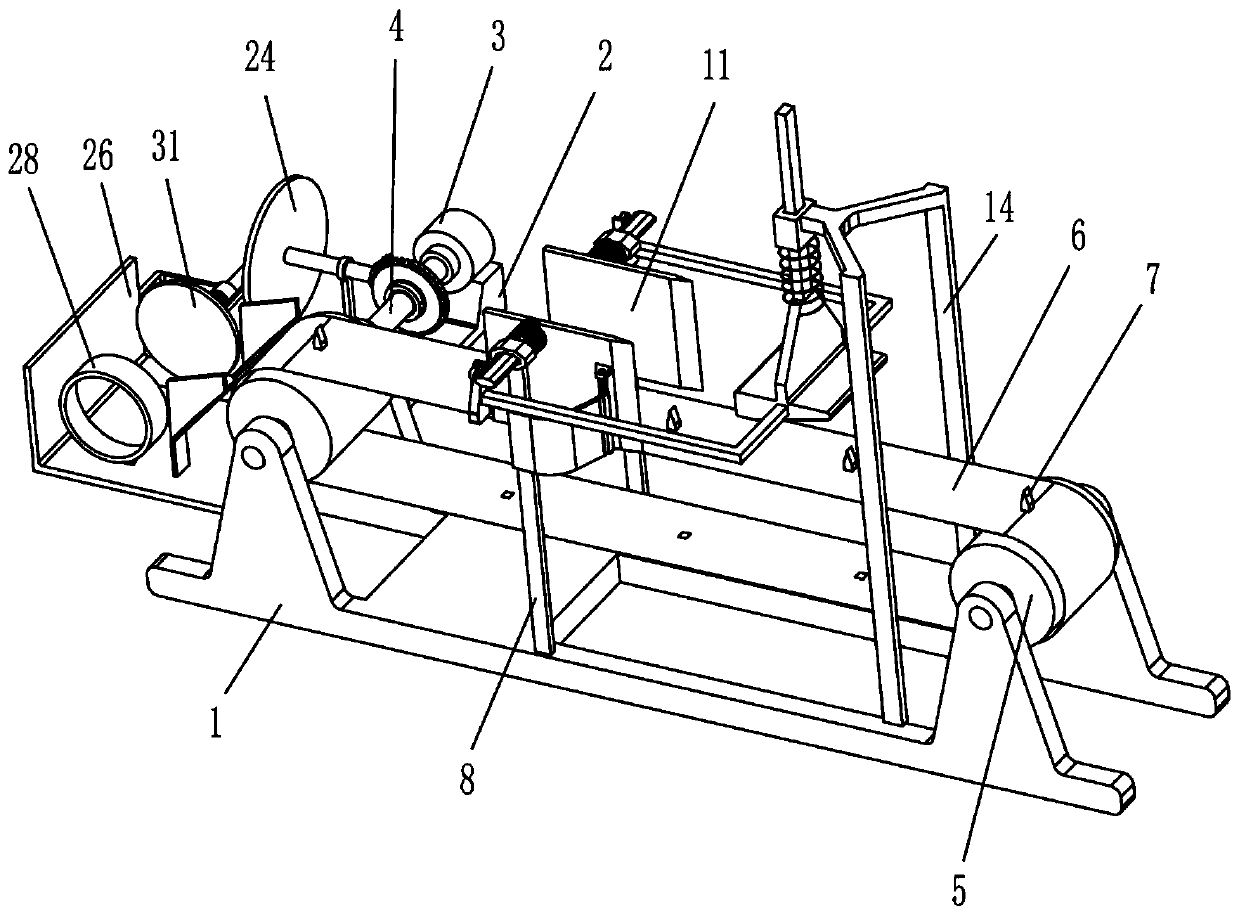

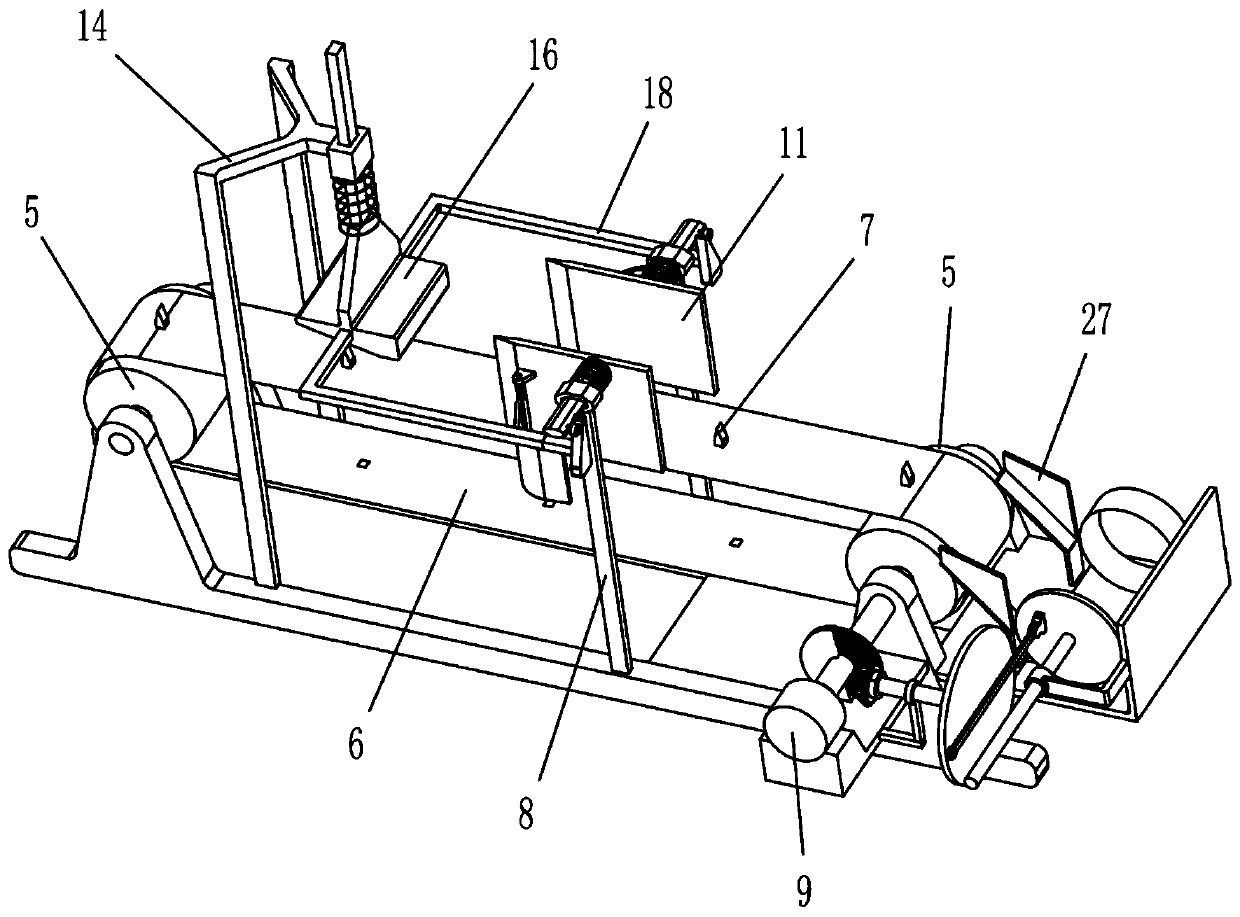

[0019] A quick coconut peeling device, such as Figure 1-5 As shown, it includes support 1, support base 2, motor 3, power shaft 4, transmission wheel 5, power belt 6, pin 7, second baffle plate 26, inclined plate 27, circular cutter 28, fixed plate 29 , a second guide sleeve 30, a guide rod 31, a push plate 32, a cutting device, a transmission device and a material retaining device, the support base 2 is fixedly installed on the left side of the support 1, and the motor 3 is fixedly installed on the support On the seat 2, one of the power shafts 4 is installed on the output shaft of the motor 3, the other power shaft 4 is installed on the right side of the support 1 through a bearing, and the two transmission wheels 5 are respectively installed on the two power shafts 4 And there is a power belt 6 connected therebetween, the pins 7 that can fix the coconut are installed on the power belt 6 at intervals, and the second baffle plate 26 is fixedly installed on the left side of t...

Embodiment 2

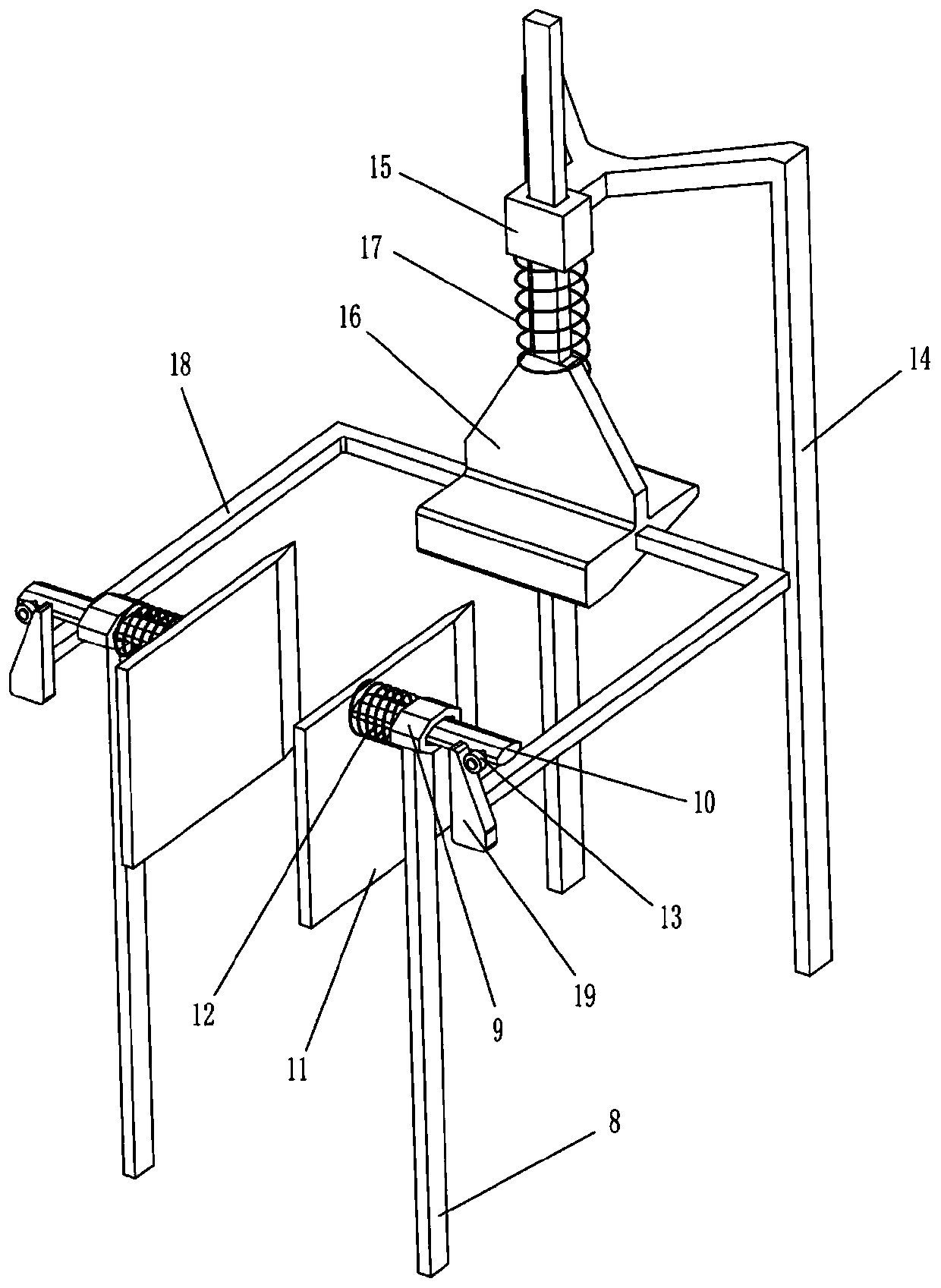

[0021] On the basis of Example 1, such as Figure 1-5 As shown, the cutting device includes a first pole 8, a first guide sleeve 9, a slide bar 10, a cutting knife 11, a return spring 12, a roller 13, a fixed rod 14, a sliding sleeve 15, and an extruding rod 16 , the first return spring 17, the first connecting rod 18 and the wedge block 19, the first pole 8 is fixedly installed on the support 1 by welding, and the two first guide sleeves 9 are fixedly installed on the two second The upper end of a rod 8, the slide bar 10 is slidably installed on the first guide sleeve 9 and the slide bar 10 can move back and forth along the first guide sleeve 9, and the cutting knife 11 is fixedly installed on the slide by welding. One end of the rod 10, one end of the return spring 12 is installed on the cutting knife 11, the other end is installed on the first guide sleeve 9 and passed by the slide bar 10, and the roller 13 is rotatably installed on the slide bar 10, so The fixed rod 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com