Paper Christmas tree and manufacturing method thereof

A production method and technology for a Christmas tree, applied in the field of printing, can solve the problems of unenvironmental protection, entanglement in a light-emitting manner, cumbersome use, etc., and achieve the effects of saving production costs, strong independent design, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

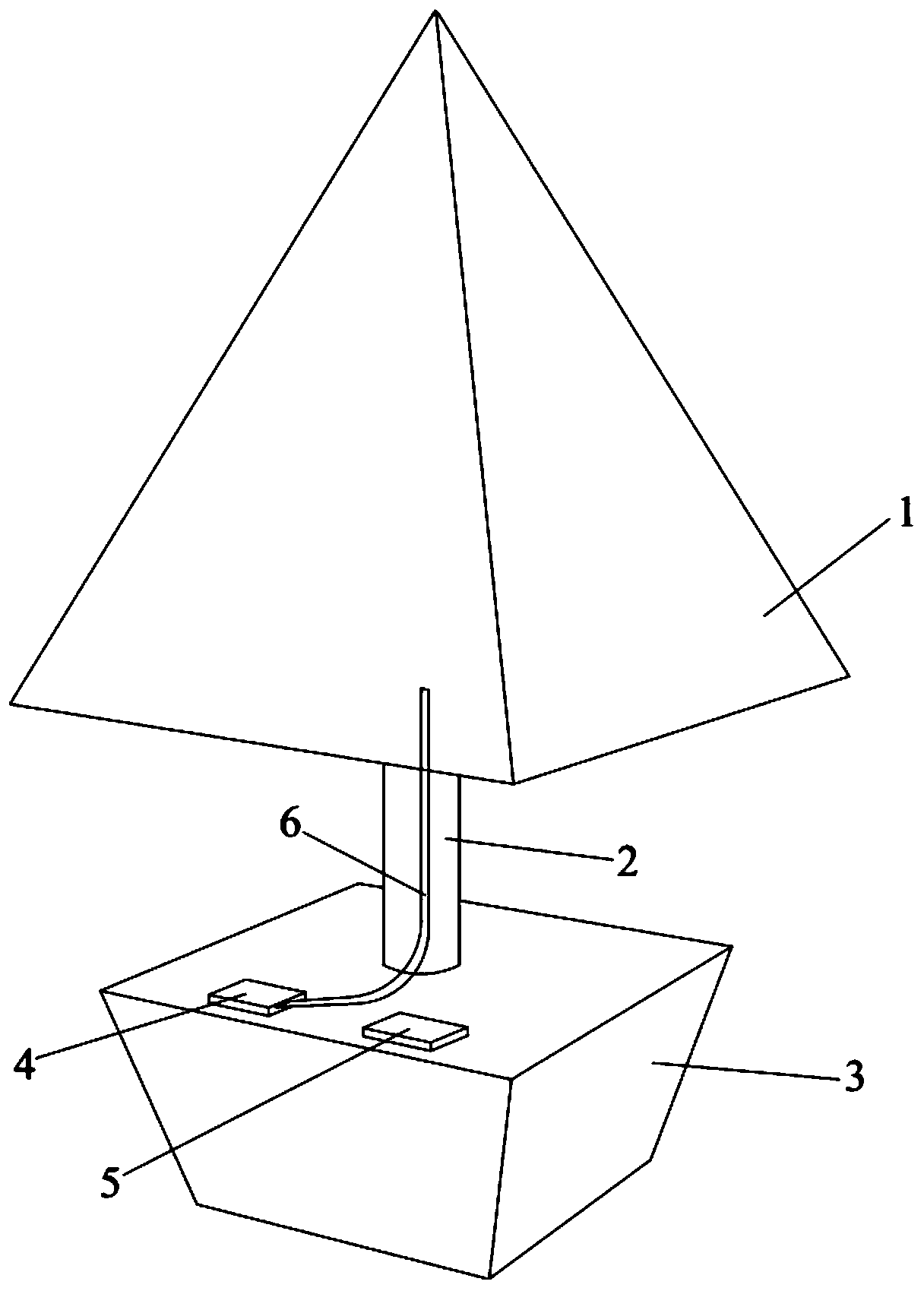

[0041] This embodiment proposes a paper Christmas tree, the whole paper Christmas tree is made of corrugated cardboard. Such as figure 1 and figure 2 As shown, the paper Christmas tree includes a tree base 3, a trunk 2 and a canopy 1, and the top surface of the tree base 3 is provided with a driver 4 and a light-sensitive music module 5, and one end of the trunk 2 is plugged in on the top of the tree base 3, and the crown 1 Plug in the other end of the trunk 2. In this embodiment, the tree base 3 is a hexahedron structure, the trunk 2 is a long cylindrical structure, and the crown 1 is a tree structure.

[0042] The entire paper Christmas tree is made of corrugated cardboard. During the manufacturing process of corrugated cardboard itself, no hazardous chemicals such as liquid chlorine or a large amount of toxic waste will be involved, which is green and environmentally friendly; corrugated cardboard can be recycled after use. Utilization, and easy to degrade, will not for...

Embodiment 2

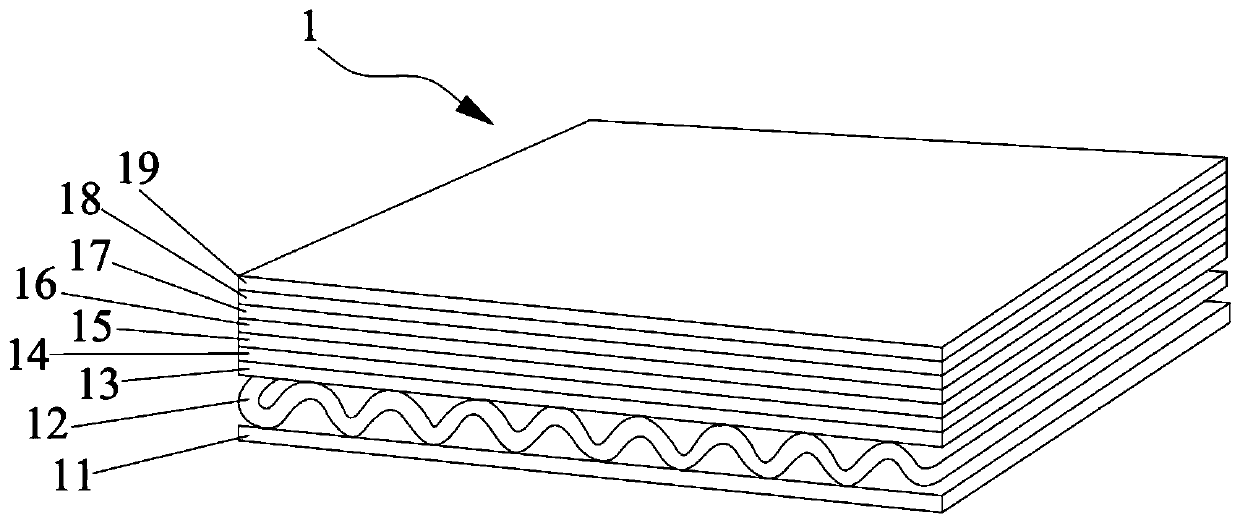

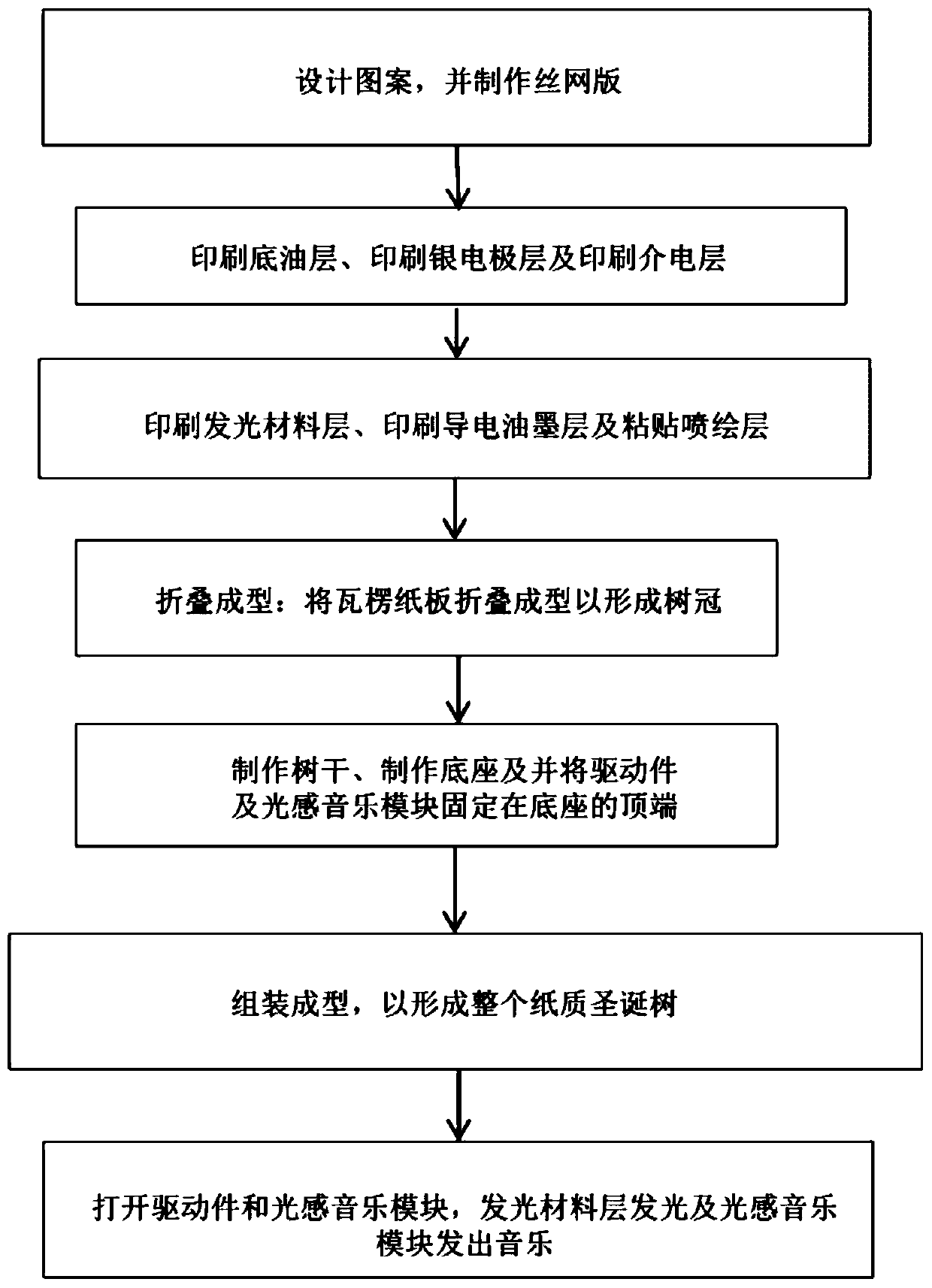

[0052] In this embodiment, a method for making a paper Christmas tree is proposed, which is used to make the paper Christmas tree in Embodiment 1. Such as image 3 As shown, specifically, the method for making a paper Christmas tree includes making a tree crown 1, wherein making the tree crown 1 includes the following steps: designing a pattern: designing a Christmas pattern on a corrugated cardboard; The printing area of pattern makes the screen plate that matches, to be used for follow-up printing process; Oil layer 14 to fill up the potholes on the corrugated cardboard.

[0053] Further, making the canopy 1 also includes the following steps: printing the silver electrode layer 15 and the dielectric layer 16: using a screen plate to print the nano-silver material on the primer layer 14 first through a screen printing process to form the silver electrode layer 15 , and then print the dielectric layer 16 on the silver electrode layer 15; print the luminescent material laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com