Half-offline plasma treatment equipment and use method thereof

A plasma and processing equipment technology, applied in the field of plasma processing equipment, can solve problems such as limited flexibility, achieve the effects of improving processing efficiency, low transformation cost, and improving product processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

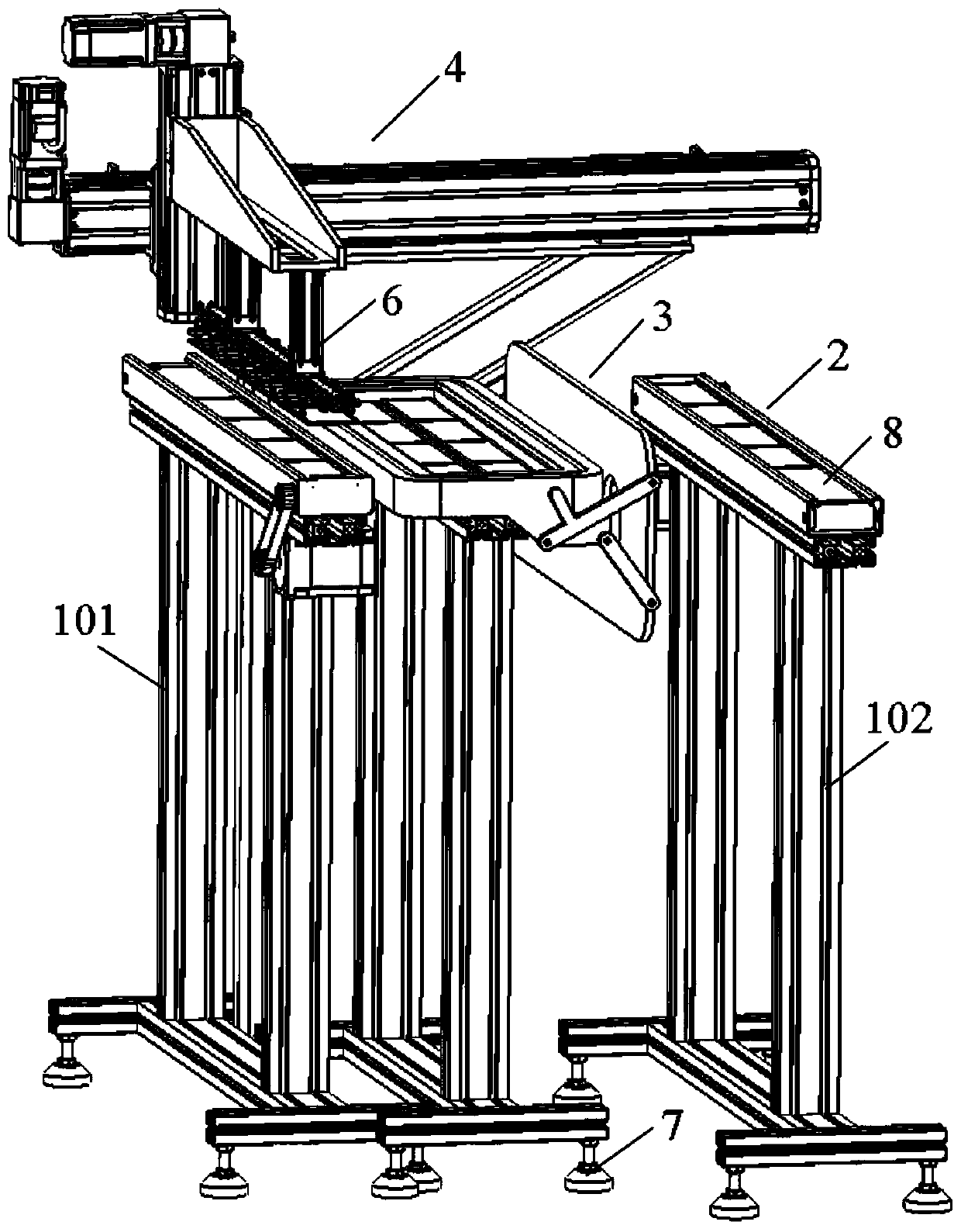

[0048] as attached figure 1 As shown, a semi-offline plasma processing equipment includes a conveyor line frame 1 , a transport assembly 2 , a vacuum chamber 3 , a moving assembly 4 , a vacuum chuck assembly 5 and a support frame 6 .

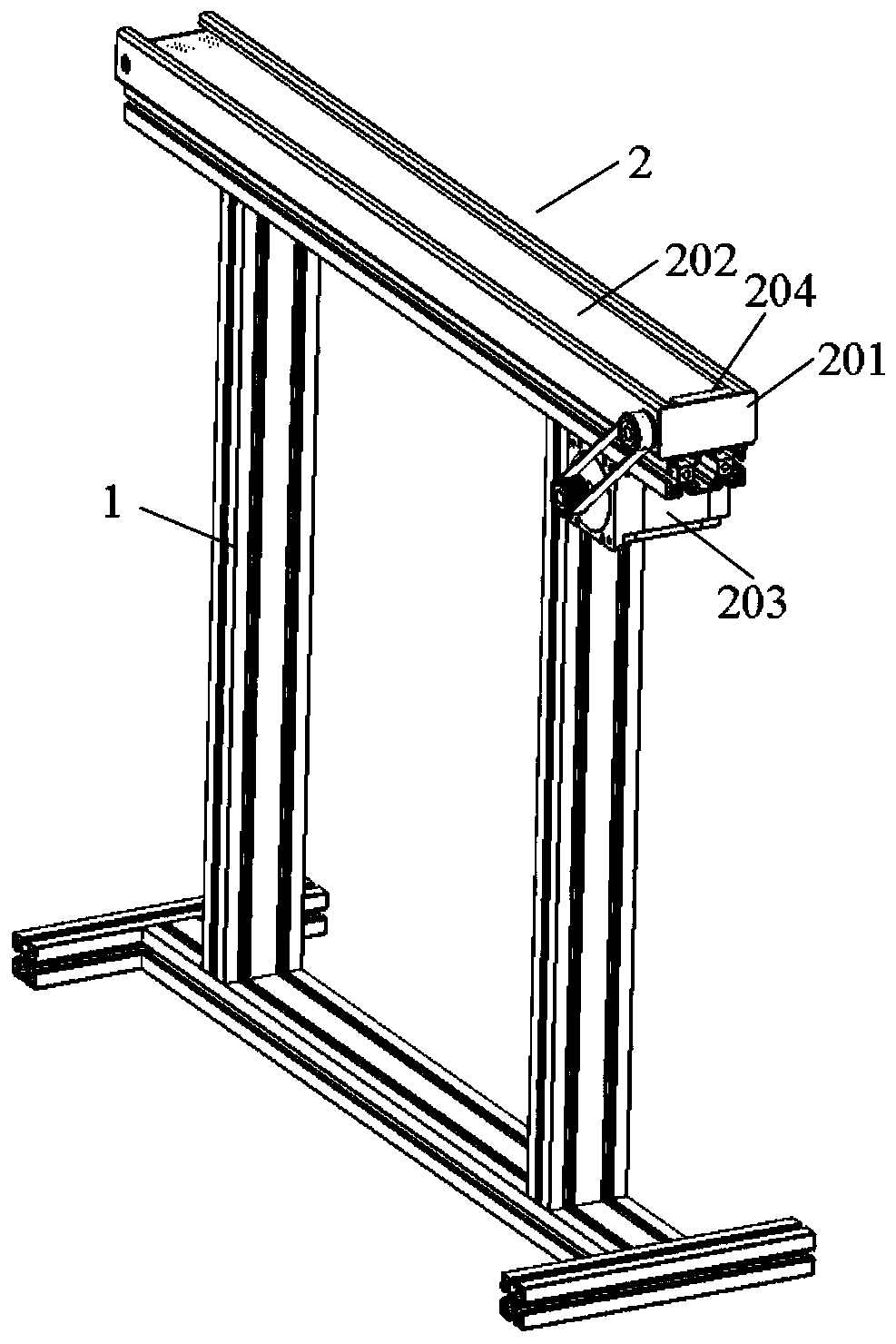

[0049] The conveying assembly 2 is arranged above the conveying line frame 1 , and the conveying assembly 2 is used for conveying the workpiece pallet 8 .

[0050] The power assembly is arranged above the support frame 6 , and the power assembly is used to drive the vacuum chuck assembly 5 to move up and down, left and right.

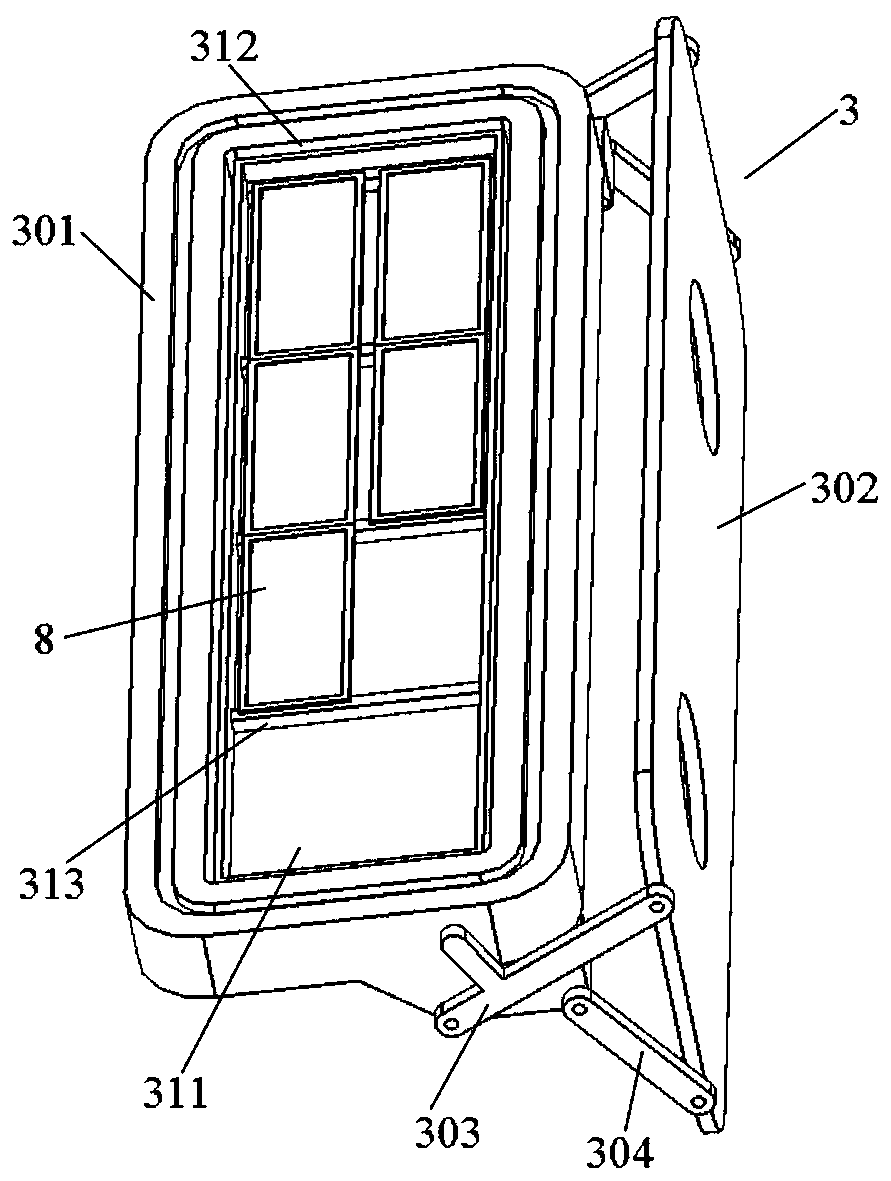

[0051] as attached figure 2 As shown, the vacuum chamber 3 includes a cavity body 301 and an upper cover 302, and the cavity body 301 and the upper cover 302 are fixedly connected by connecting rods.

[0052] Further, the connecting rod includes a long connecting rod 303 and a short connecting rod 304 , and the two ends of the long connecting rod 303 and the short connecting rod 304 are respectively fixed on one side o...

Embodiment 2

[0073] Based on the above-mentioned embodiment 1, a method for using a semi-offline plasma processing equipment includes the following steps:

[0074] S1, the transmission motor 203 is turned on, and the workpiece tray 8 is transmitted through the first transmission component, that is, the feeding end, and is transmitted on the transmission belt 202;

[0075] S2, the vacuum chamber 3 is opened, the power assembly drives the vacuum chuck assembly 5 to move up and down, left and right, at the same time, the vacuum chuck assembly 5 sucks the workpiece tray 8 and places it in the cavity 301, the vacuum chuck assembly 5 returns to its position, and the upper cover 302 is closed, vacuumized for plasma treatment;

[0076] Specifically, the X-axis power assembly 401 drives the left and right movement of the vacuum chuck assembly 5 by driving the moving frame 423 to move left and right; the Z-axis power assembly 402 drives the vacuum chuck assembly 5 to move up and down by driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com