Dispersed asphalt regenerant and preparation method thereof

An asphalt regenerant, dispersing technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of high proportion of new materials, difficult to achieve recycled asphalt mixture, low content of old materials, etc., to improve performance, The effect of strong environmental protection and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

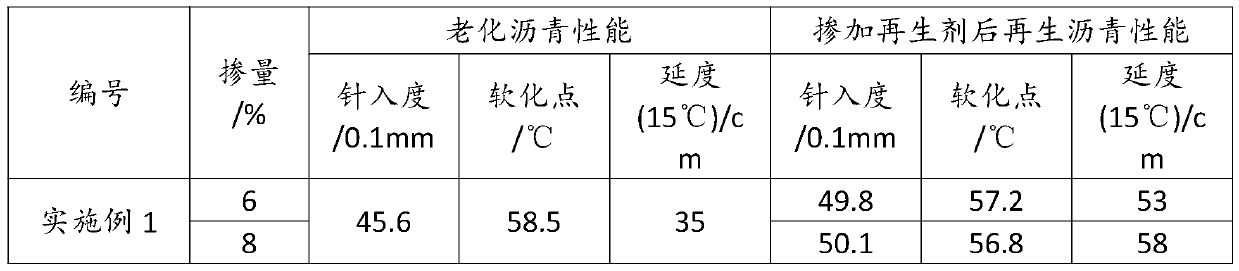

Embodiment 1

[0025] The present embodiment prepares a kind of dispersed asphalt regenerant, specifically comprises the following steps:

[0026] (1) Preparation of tall oil-based surfactant: select and weigh tall oil and concentrated sulfuric acid in a molar ratio of 1:0.3, put the tall oil in the reaction kettle, add concentrated sulfuric acid while stirring, and the reaction temperature is 45°C. The stirring speed is 450r / min, the reaction time is 45min, and the intermediate product is obtained; sodium hydroxide is added while stirring in the reaction kettle with the intermediate product, the reaction temperature is 30°C, the stirring speed is 350r / min, until the pH of the solution=9, stop Add alkali to obtain tall oil-based surfactant;

[0027] (2) Preparation of modified cardanol surfactant: cardanol and concentrated sulfuric acid are selected and weighed in a molar ratio of 1:0.2, cardanol is put into the reaction kettle, and concentrated sulfuric acid is added while stirring, the rea...

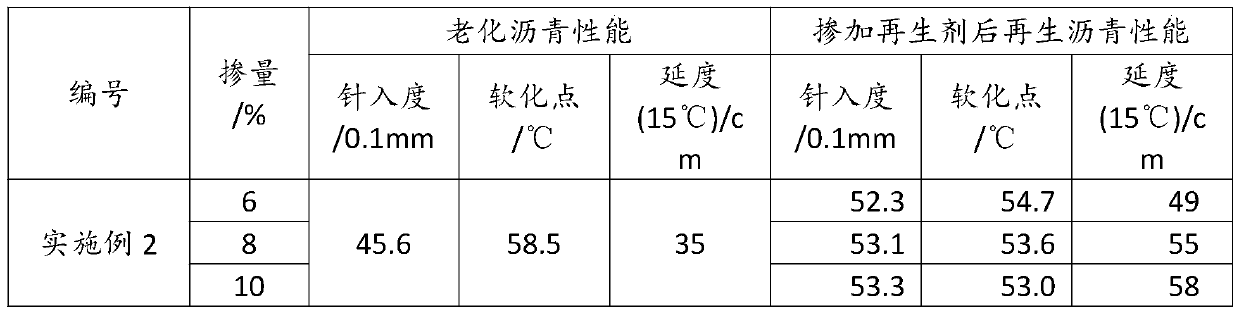

Embodiment 2

[0035] The present embodiment prepares a kind of dispersed asphalt regenerant, specifically comprises the following steps:

[0036] (1) Preparation of tall oil-based surfactant: select and weigh tall oil and concentrated sulfuric acid at a molar ratio of 1:0.25, put the tall oil in the reaction kettle, add concentrated sulfuric acid while stirring, and the reaction temperature is 40°C. The stirring speed is 450r / min, the reaction time is 50min, and the intermediate product is obtained; sodium hydroxide is added while stirring in the reactor containing the intermediate product, the reaction temperature is 30°C, the stirring speed is 350r / min, until the solution pH=9.5, stop Add alkali to obtain tall oil-based surfactant;

[0037] (2) Preparation of modified cardanol surfactant: cardanol and concentrated sulfuric acid are selected and weighed in a molar ratio of 1:0.25, cardanol is put into the reaction kettle, and concentrated sulfuric acid is added while stirring, the reaction...

Embodiment 3

[0054] In this example, the dispersed asphalt rejuvenator prepared in Example 1 was used as the regenerant for preparing the regenerated asphalt mixture. In addition, aged asphalt mixture and new asphalt mixture were also selected, and the gradation of the aged asphalt mixture was For AC-13C, the mixing ratio of aged asphalt mixture and new asphalt mixture is 3:7 and 4:6, and the dosage of dispersed asphalt rejuvenator is selected as 6%, 8%, and 10% of the mass of aged asphalt in the mixture. %, the properties of the prepared recycled asphalt mixture are shown in Table 5:

[0055]

[0056] table 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com