Novel extensible type modularized combined frame

A modular and new technology, applied in building types, special buildings, small buildings, etc., can solve the problems of difficult repair and replacement, long construction time, complicated installation process, etc., and achieve great social and economic benefits. Convenient storage and transportation, the effect of filling technology gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

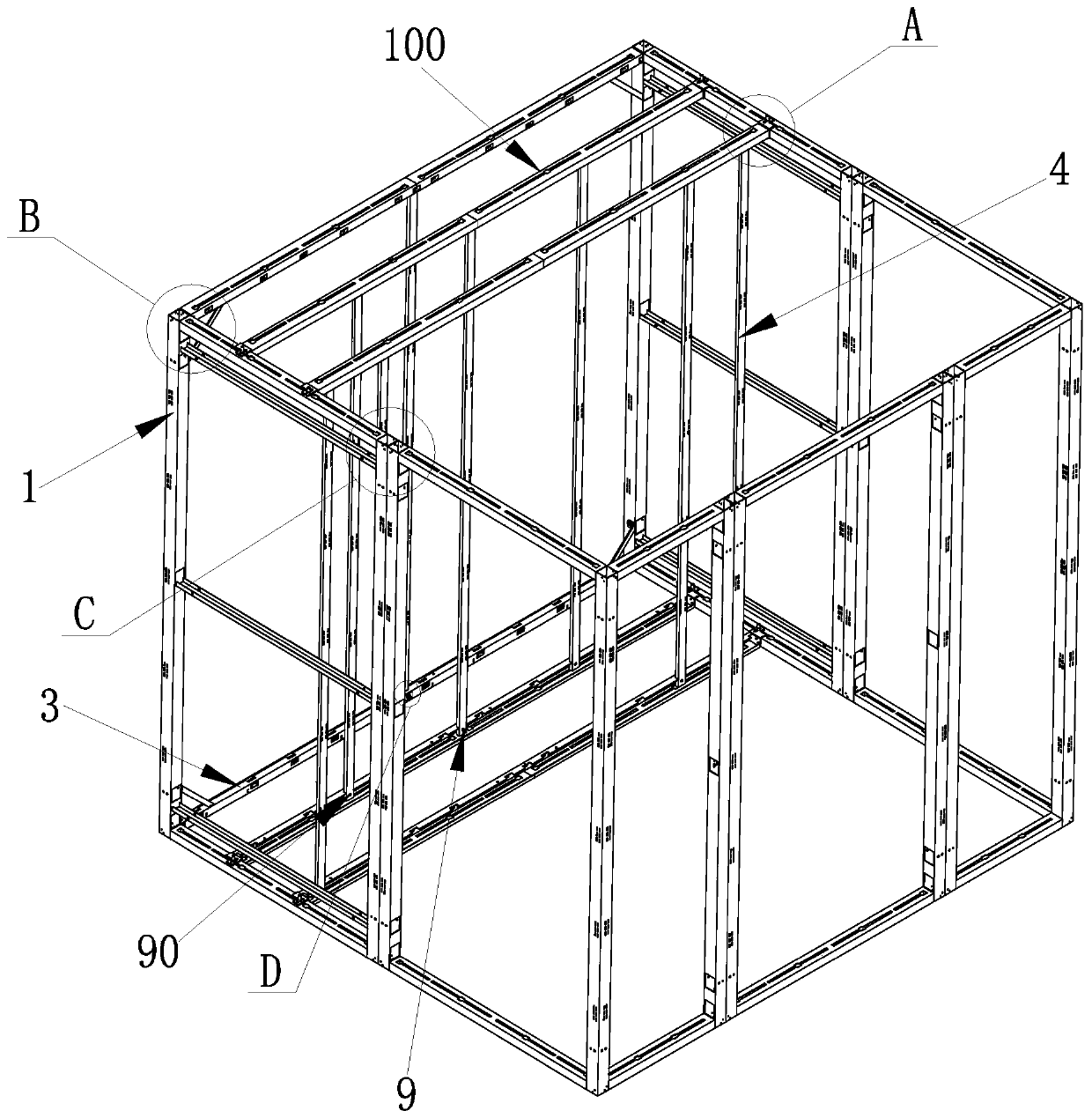

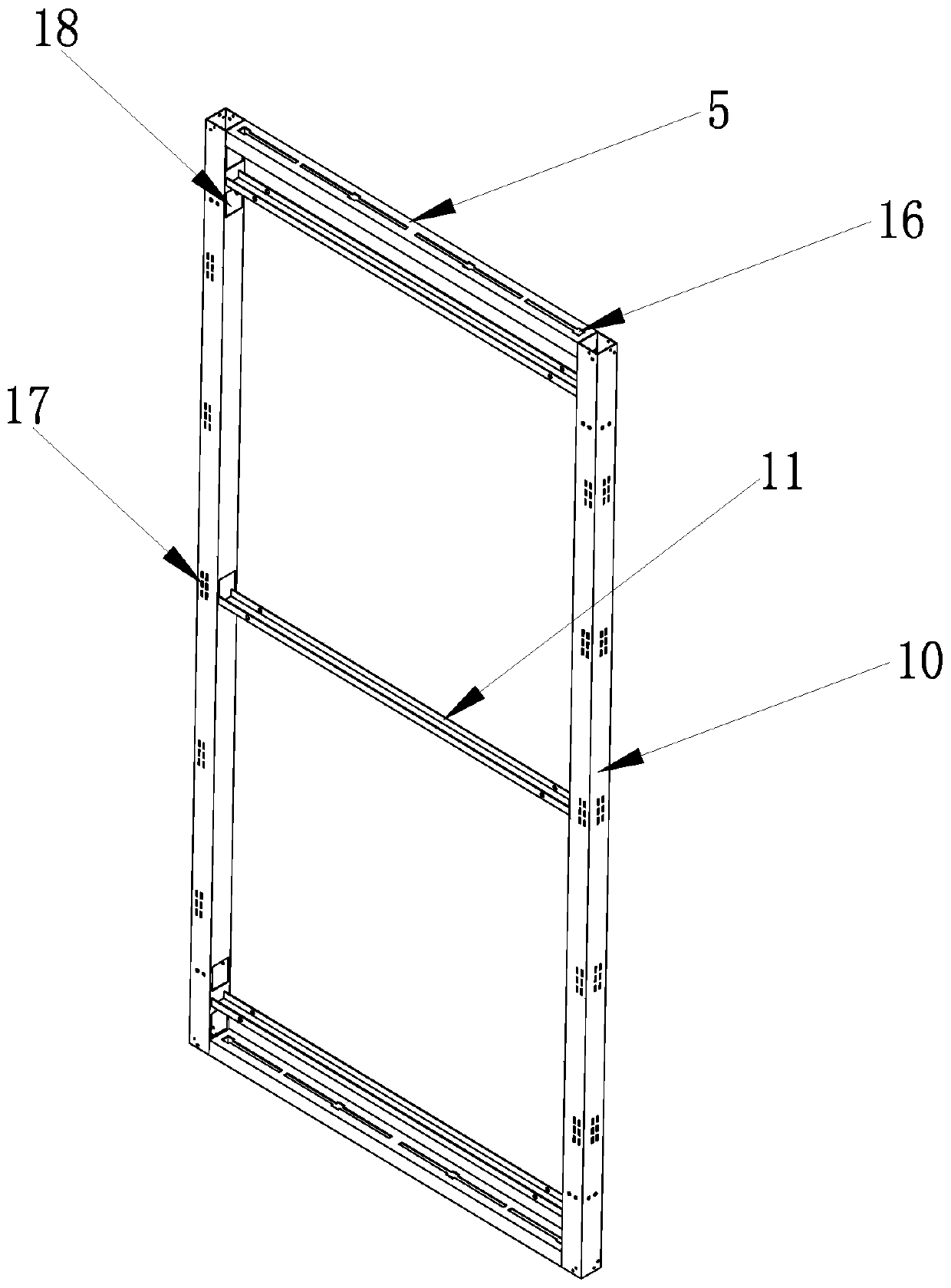

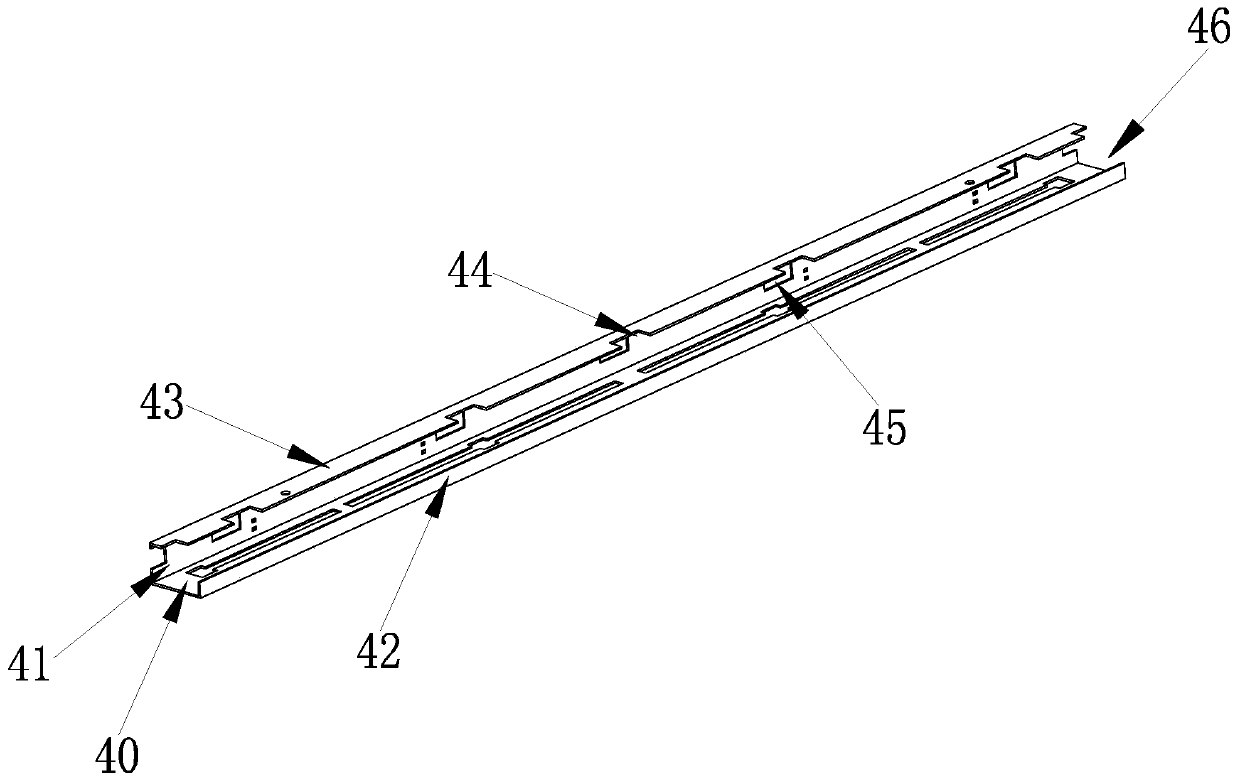

[0036] Such as Figure 1-8 As shown, a new type of extensible modular composite frame provided in this embodiment includes at least two loading frames 1, and the two loading frames 1 are detachably connected by several sets of beam assemblies 100; The assembly 100 includes several sets of upper frame beams 2 and lower frame beams 3 arranged symmetrically up and down; several upper support plate grooves 36 are formed on the upper frame beams 2, and correspondingly, several upper support plate grooves 36 are formed on the lower frame beams 3. 36 corresponding to the lower support plate groove 46, wherein, the position of the upper support plate groove 36 and the lower support plate groove 46 are relatively arranged, and a support rod 4 is inserted between the upper support plate groove 34 and the lower support plate groove 46 to support Both sides of the rod 4 are also equipped with a limit device 9 for positioning the support rod 4 on the upper support plate groove 36 and the l...

Embodiment 2

[0051] Such as Figure 9-10 As shown, this embodiment provides a new type of extensible modular composite frame, wherein adjacent upper frame beams 2 or lower frame beams 3 are detachably connected by at least one hanging plate frame 12, in this embodiment Hanging board frame 12 is provided with two, and two hanging board frames 12 are equidistantly arranged between adjacent upper frame beam 2 or lower frame beam 3, and the length of hanging board frame 12 can be according to adjacent upper frame beam 2 or adjacent The distance between the lower frame beams 3 is selected. The two sides of the hanging plate frame 12 are fixed with hanging plates 13, and guide holes 14 are formed on the hanging plate 13. The guiding holes 14 correspond to the positions of the guide grooves 50, and the hanging plate screws 15 passes through the guide groove 50 and the guide hole 14, and is used to fasten the hanging board frame 12 on the upper frame beam 2 and the lower frame beam 3, wherein the ...

Embodiment 3

[0055] Such as Figure 11-12 As shown, a new extensible modular composite frame is provided in this embodiment, wherein fastening glass clips 19 are detachably installed on the bottom and top of the horizontal tube 5 of the loading frame 1, and the glass clips 19 are set no less than There are four, through the installation of four fastening glass clips 19, forming a card slot for adding glass on four sides, which can be directly inserted into the toughened glass at the assembly site, improving the various assembly possibilities of the entire frame, high interchangeability, suitable for wide range.

[0056] For other contents of this embodiment, refer to Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com