Side pump signal beam combiner for realizing flat-topped light beam and preparation method thereof

A flat-top beam and beam combiner technology, which is applied in the directions of light guides, optics, instruments, etc., can solve the problems of non-universality of incident light, high process and cost, and no requirements for beam energy distribution, and achieve easy all-fiberization. Integrated, short production cycle, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

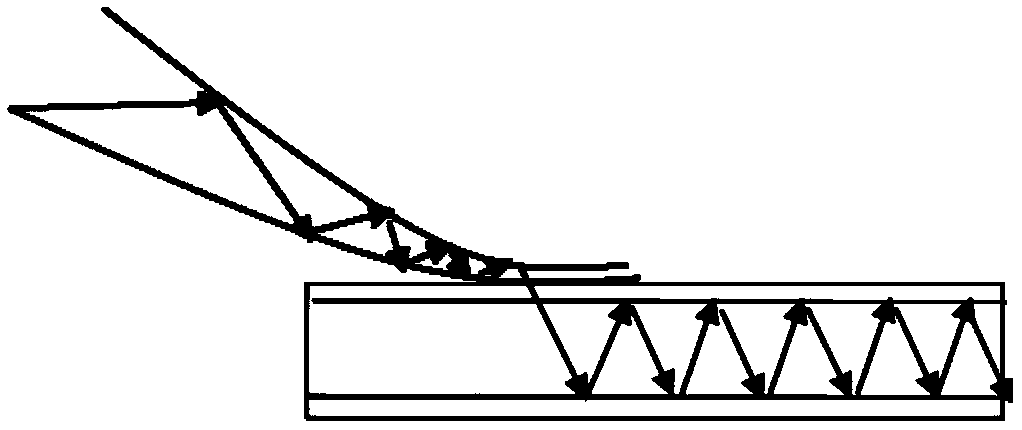

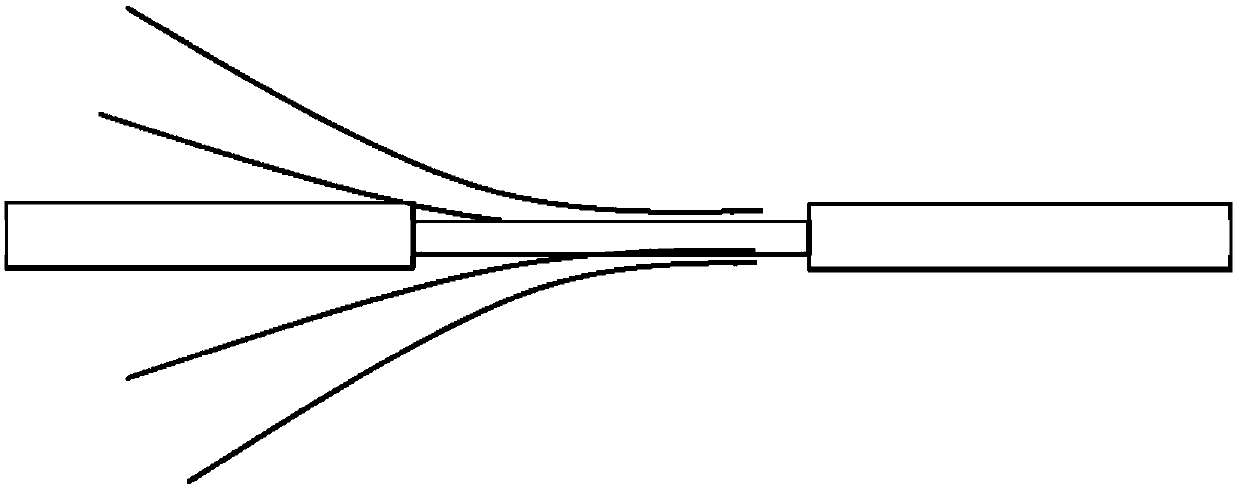

[0052] Such as figure 2 As shown, a side-pump signal combiner includes a main signal fiber and at least one side-arm input fiber. (two side arms are shown in the picture)

[0053] The main signal fiber has at least two layers of waveguide structure, the refractive index of the inner waveguide structure must be higher than that of the outer waveguide structure, and the main signal fiber is required to be a multimode fiber for the laser of the transmission wavelength.

[0054] The main signal fiber preferably has a two-layer waveguide structure, the outer waveguide structure is the cladding, and the inner waveguide structure is the core. The specific parameters can be selected from any of the following:

[0055]

[0056] The side arm input fiber preferably has a two-layer waveguide structure, the outer waveguide structure is the cladding, and the inner waveguide structure is the core. The specific parameters can be selected from any of the following:

[0057]

[0058] T...

Embodiment 2

[0064] Both the main signal fiber and the side arm signal fiber have a two-layer waveguide structure, the main signal fiber is 50 / 400, NA: 0.15 / 0.46, and the side arm input fiber is 50 / 125, NA: 0.12;

[0065] Using oxyhydrogen flame as heating source;

[0066] Side arm input fiber pretreatment: taper the side arm input fiber, and the diameter of the taper after the taper is 50 μm;

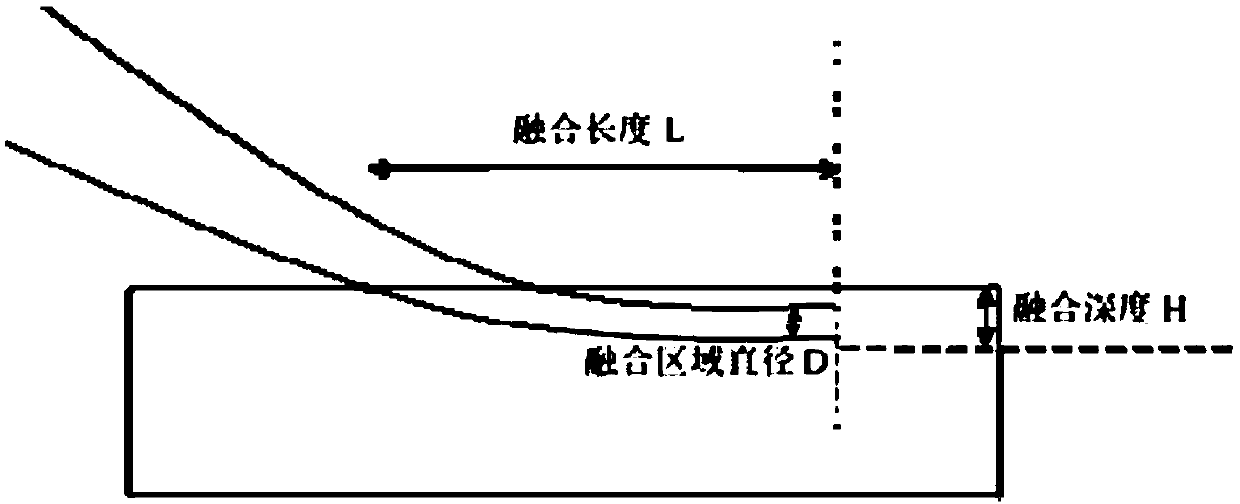

[0067] Bonding of the side arm input fiber and the main signal fiber: the main signal fiber and the side arm input fiber are fixed with a special clamp after the coating layer is stripped, and the side arm input fiber is stretched and fitted on the surface of the main signal fiber while the fiber does not deform or drop , fusion length L=2mm;

[0068] Side fusion of the side arm input fiber and the main signal fiber: control the fusion depth of the side arm input fiber and the main signal fiber by controlling the temperature of the oxyhydrogen flame and the length of the fusion time, and the fusio...

Embodiment 3

[0072] Both the main signal fiber and the side arm signal fiber have a three-layer waveguide structure, the main signal fiber is 50 / 70 / 660, NA:0.22, and the side arm input fiber is 100 / 120 / 360, NA:0.22;

[0073] Using oxyhydrogen flame as heating source;

[0074] Side arm input fiber pretreatment: taper the side arm input fiber, and the diameter of the taper after the taper is 100 μm;

[0075] Bonding of the side arm input fiber and the main signal fiber: the main signal fiber and the side arm input fiber are fixed with a special clamp after the coating layer is stripped, and the side arm input fiber is stretched and fitted on the surface of the main signal fiber while the fiber does not deform or drop , fusion length L=5mm;

[0076] Side fusion of the side arm input fiber and the main signal fiber: control the fusion depth of the side arm input fiber and the main signal fiber by controlling the temperature of the oxyhydrogen flame and the length of the fusion time, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com