Iron core for anode saturable reactor, preparation method thereof and anode saturable reactor

A reactor and iron core technology, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor core, transformer/inductor coil/winding/connection, etc. The effect of moderate paint volume, noise reduction and strip burr reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

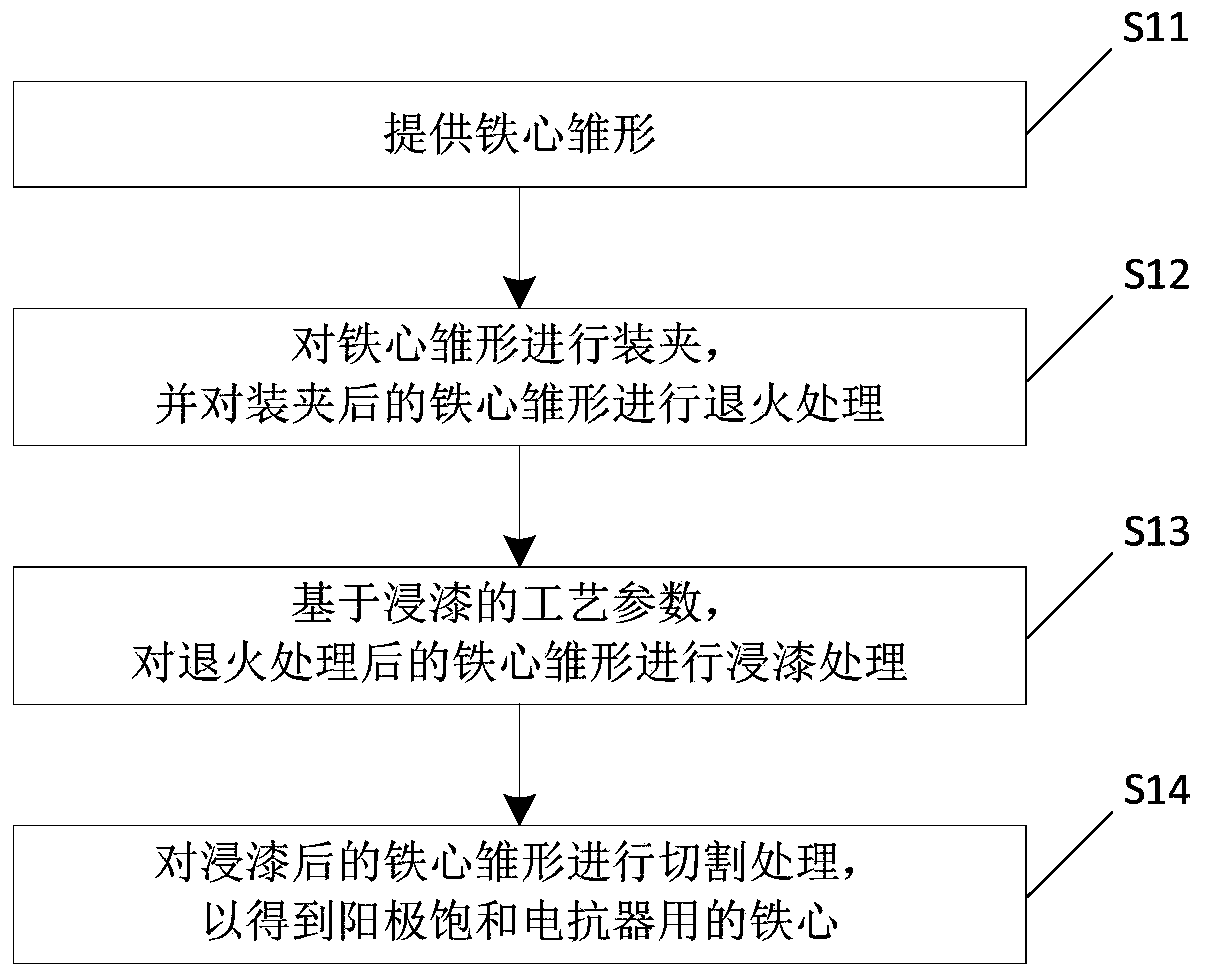

[0041] The embodiment of the present invention provides a method for preparing an iron core for an anode saturable reactor, such as figure 1 shown, including:

[0042] S11, provide the core prototype.

[0043] Wherein, the prototype of the iron core can be formed in advance, or can be prepared by using target raw materials when preparing the iron core, and there is no restriction on the timing of forming the prototype of the iron core.

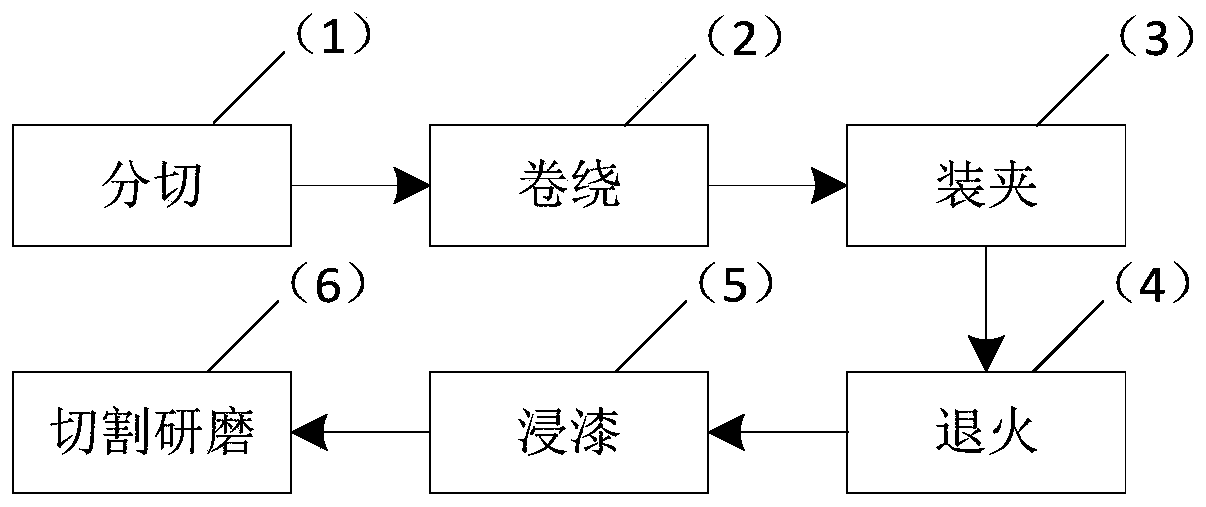

[0044] In this embodiment, it is described by taking the prototype of the iron core which is prepared from raw materials when preparing the iron core as an example. Specifically, the above S11 includes the following steps:

[0045] (1) Control the uncoiler to provide target raw materials.

[0046] Set the target raw material on the uncoiler, and control the work of the uncoiler to provide the target raw material to the slitting machine. Wherein, the target raw material may be an industrial finished plate of ultra-thin oriented silicon stee...

Embodiment 2

[0064] This embodiment provides a method for preparing an iron core for an anode saturable reactor, and the specific preparation method is the same as that of Embodiment 1. Wherein, different from embodiment 1 is:

[0065] The uncoiling tension of the uncoiler is 10kg, and the winding tension is 10kg;

[0066] The gap between the slitting knife surface is 0.5mm, the upper and lower knife error is 0.5mm, the edge wire width is 10mm, and the slitting speed is 500m / min;

[0067] The number of coils of the same type of core differs by 10 coils, and the coil thickness differs by 0.5mm;

[0068] The clamping pressure is 10 tons / m 2 ;

[0069] The oxygen content in the annealing furnace is 100ppm, the temperature in the annealing furnace is raised to 1000°C, the holding time is 1h, and the cooling rate is 2°C / min when the temperature in the furnace drops to 500°C;

[0070] The vacuum degree of dipping paint is 1000Pa, the dipping paint pressure is 1MPa, the duration of dipping pa...

Embodiment 3

[0072] This embodiment provides a method for preparing an iron core for an anode saturable reactor, and the specific preparation method is the same as that of Embodiment 1. Wherein, different from embodiment 1 is:

[0073] The uncoiling tension of the uncoiler is 5kg, and the winding tension is 5kg;

[0074] The gap between the slitting knife surface is 0.1mm, the upper and lower knife error is 0.1mm, the edge wire width is 5mm, and the slitting speed is 200m / min;

[0075] The number of coils of the same type of core differs by 20 coils, and the coil thickness differs by 1mm;

[0076] The clamping pressure is 5 tons / m 2 ;

[0077] The oxygen content in the annealing furnace is 300ppm, the temperature in the annealing furnace is raised to 850°C, the holding time is 5h, and the cooling rate is 2°C / min when the temperature in the furnace drops to 500°C;

[0078] The vacuum degree of dipping paint is 1000Pa, the dipping paint pressure is 0.5MPa, the duration of dipping paint h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| noise | aaaaa | aaaaa |

| noise | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com