Intelligent sheep flock feeding system

A flock and intelligent technology, applied in the field of intelligent flock feeding system, can solve the problems of wasting time, unable to cover the feed trough, time-consuming and labor-intensive, etc., and achieve the effect of increasing economic benefits, preventing livestock loss, and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

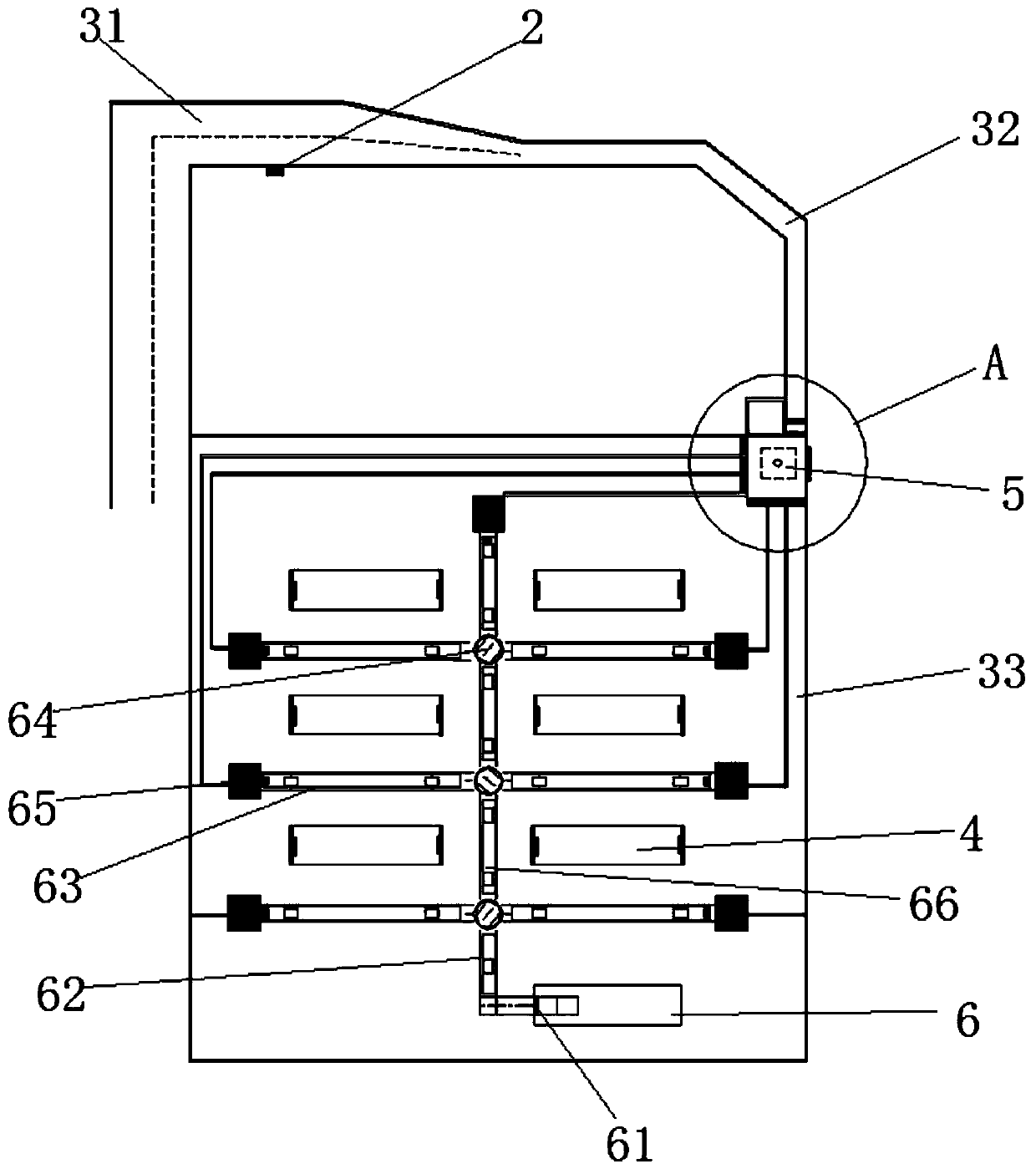

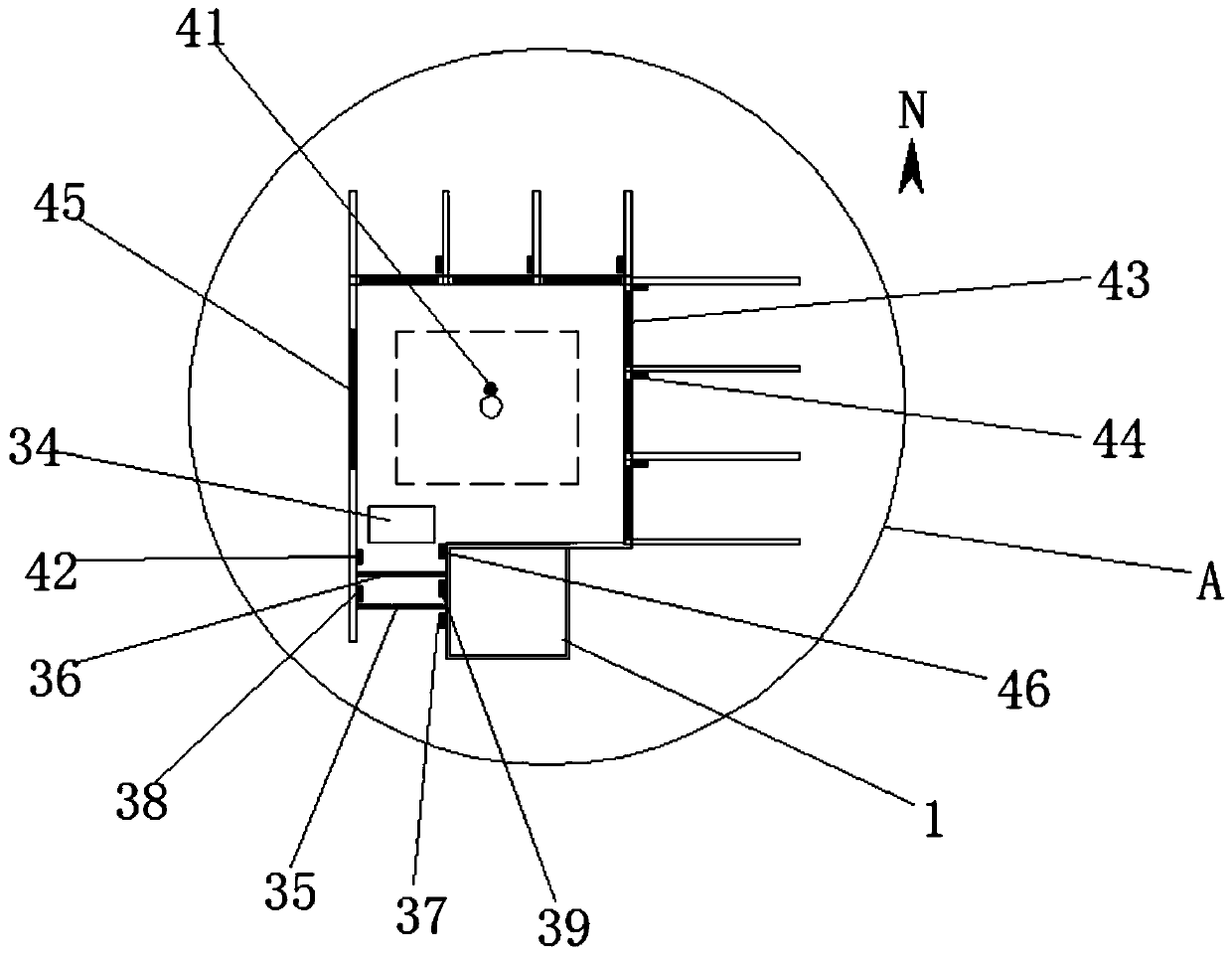

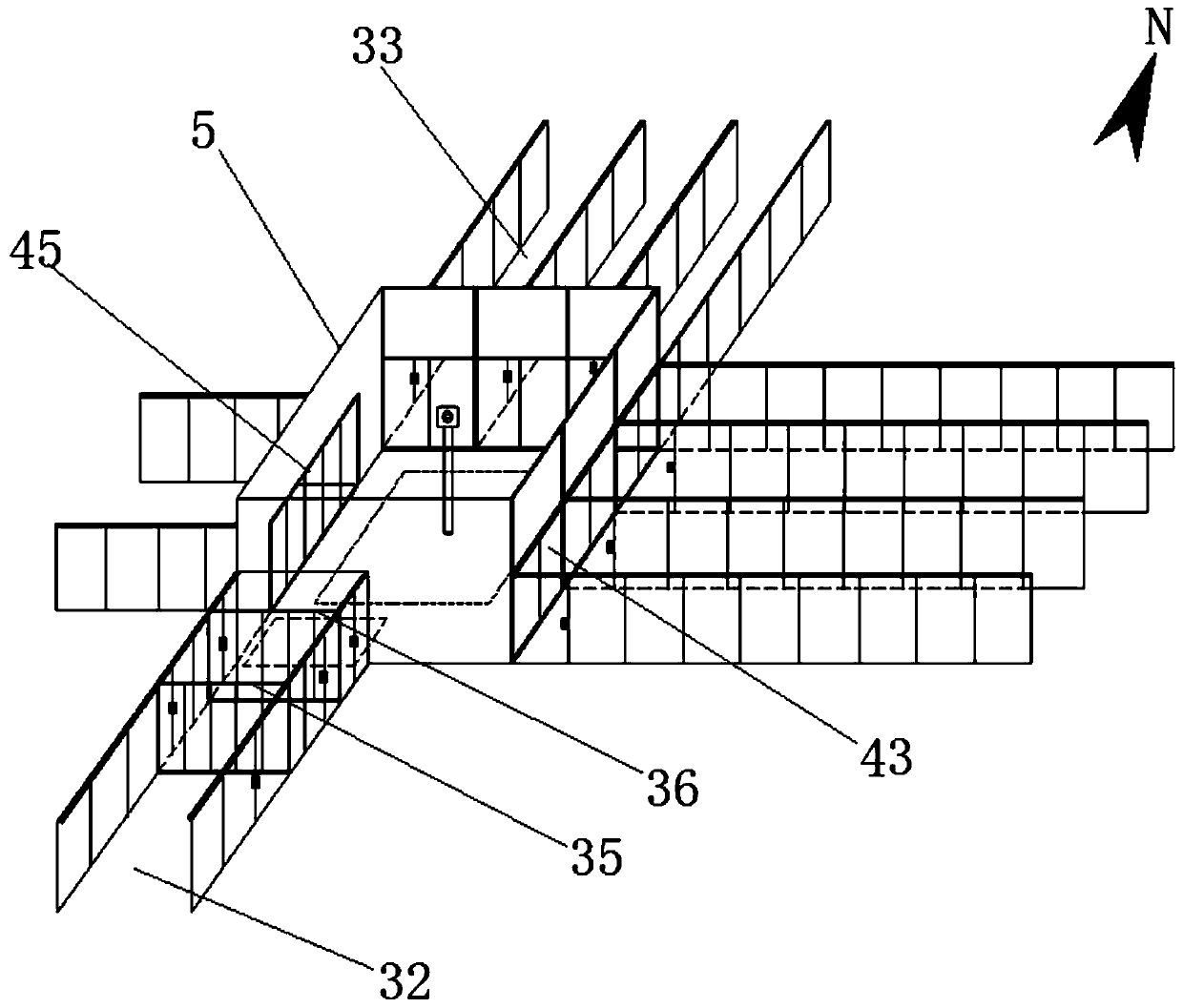

[0025] Such as Figure 1-7 as shown,

[0026] This embodiment provides an intelligent sheep flock breeding system including a central control system, an information collection system, an intelligent access control system and an adaptive feeding system arranged in a sheep farm, where the sheep house 4 and other areas are two Partially constituted, there are evenly distributed sheep houses 4 and an activity area outside the house in the area of the sheep house 4. The central control system includes a central control room 1 and a host computer, and the host computer is located in the central control room 1. The upper computer is the control center of the entire intelligent sheep farm feeding system, which stores all the ear tag infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com