Method for optimizing enzymolysis ultrasonic assisted extraction of folium artemisiae argyi total flavone by response surface method

An enzymatic hydrolysis-assisted, response surface methodology technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

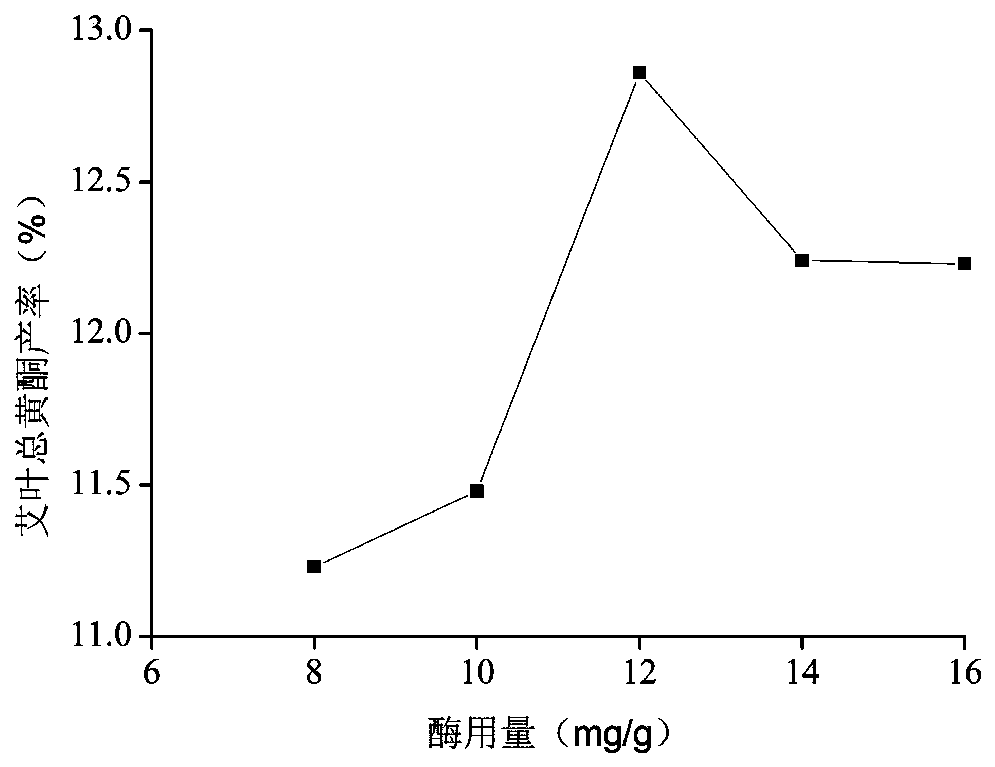

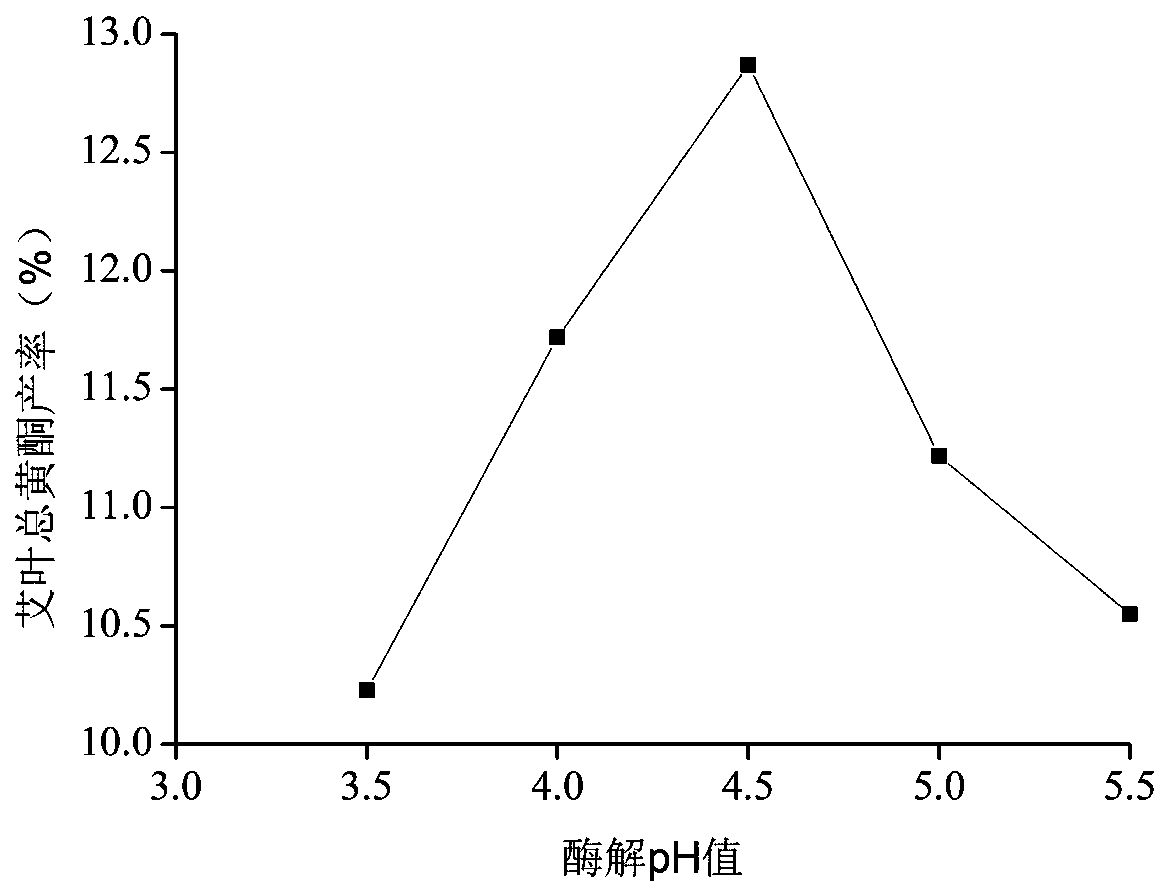

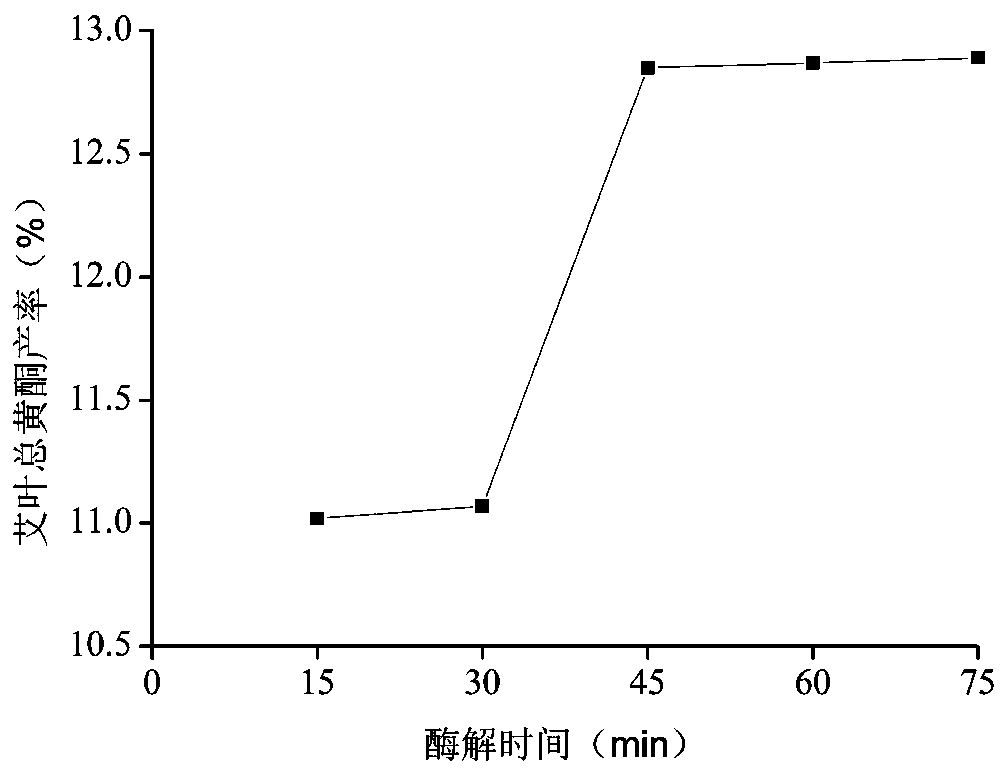

[0067] Artemisia argyi is dried, oven-dried, and it is pulverized into 60 mesh granules. Weigh 10.0000g of Artemisia argyi powder, add 120mg compound enzyme (cellulase: pectinase=2:1), add 150mL acetic acid-sodium acetate buffer solution, pH value is 4.5, enzymolysis at 50°C for 45min, filter, Obtain the enzymolysis filtrate and filter residue; add 150mL of 60% ethanol to the filter residue, ultrasonically extract for 20min, and the ultrasonic power is 200W, to obtain the alcohol extract; combine the enzymolysis filtrate and the alcohol extract, use a rotary evaporator to concentrate the extract, and Dry in a vacuum oven for 24 hours, weigh and record the crude extract of total flavonoids from Artemisia argyi leaves. The yield of total flavonoids from Artemisia argyi leaves was determined by ultraviolet-visible spectrophotometry to be 12.79%.

Embodiment 2

[0069] Artemisia argyi is dried, oven-dried, and it is pulverized into 60 mesh granules. Weigh 10.0000g of Artemisia argyi powder, add 140mg compound enzyme (cellulase: pectinase=2:1), obtain enzymolysis filtrate and filter residue; add 150mL acetic acid-sodium acetate buffer solution, pH value is 4.5, at 50 ℃ After 60 minutes of enzymolysis, filter, add 150mL of 60% ethanol to the filter residue, ultrasonically extract for 20min, and the ultrasonic power is (200W), to obtain the alcohol extract; combine the enzymolysis filtrate and the alcohol extract, and use a rotary evaporator to concentrate the extract , and dried in a vacuum oven for 24 hours, weighed and recorded the crude extract of total flavonoids from Artemisia argyi leaves. The yield of total flavonoids from Artemisia argyi leaves was determined by UV-visible spectrophotometry to be 12.30%.

Embodiment 3

[0071] Artemisia argyi is dried, oven-dried, and it is pulverized into 60 mesh granules. Weigh 10.0000g of mugwort leaves powder, add 100mg compound enzyme (cellulase: pectinase=2:1), add 150mL acetic acid-sodium acetate buffer solution, pH value is 4.5, enzymolysis at 50°C for 30min, filter, Obtain enzymolysis filtrate and filter residue; add 60% ethanol 150mL to filter residue, ultrasonic extraction 20min, ultrasonic power is (200W), obtain alcohol extract; Combine enzymolysis filtrate and alcohol extract, and use vacuum oven to dry, The drying time was 24 hours, and the crude extract of total flavonoids from Artemisia argyi leaves was weighed and recorded. The yield of total flavonoids in Artemisia argyi leaves was determined to be 12.25% by ultraviolet-visible spectrophotometry

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com