Ultra-light steel wire rope linkage type space docking mechanism

A space docking and wire rope technology, which is applied to the docking devices of space navigation vehicles, motor vehicles, space navigation equipment, etc. The effect of reliable separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

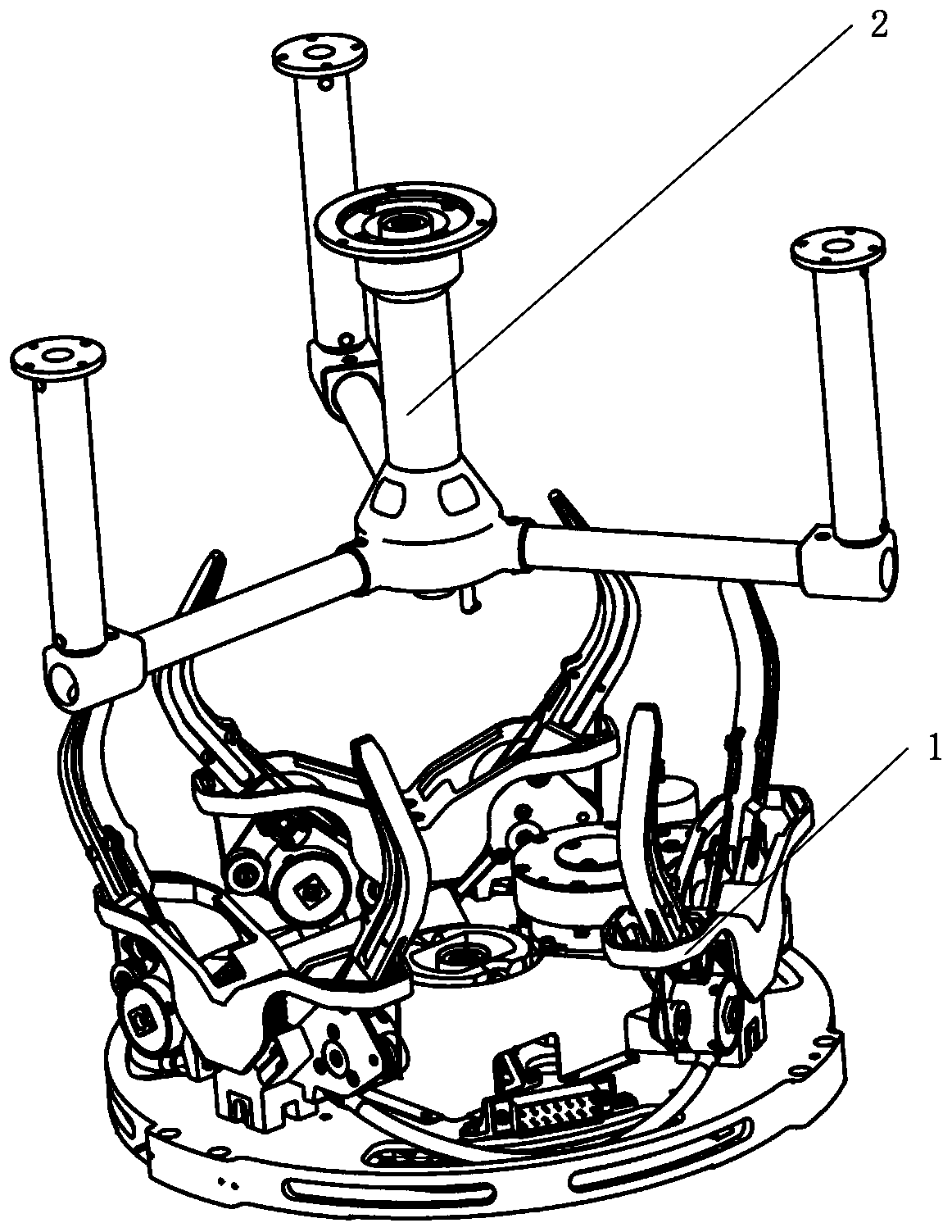

[0022] The invention provides an ultra-light steel wire rope linkage space docking mechanism, such as figure 1 As shown, the space docking mechanism is composed of two parts, the active end 1 and the passive end 2. The active end 1 and the passive end 2 are respectively installed on two independent aircrafts. When docking, each claw of the active end 1 The mechanisms correspond to the positions of the lock handles of the passive end 2 respectively.

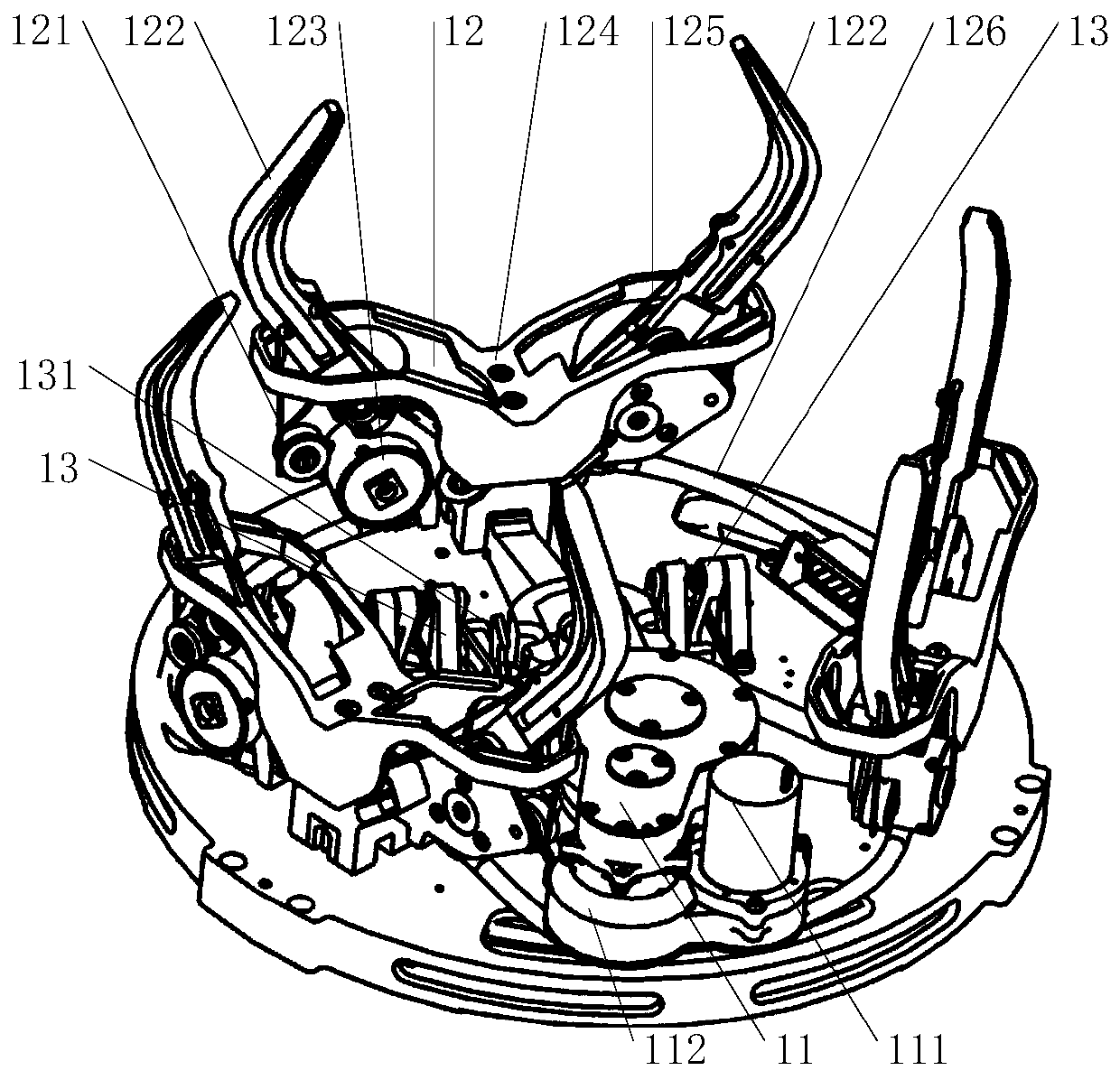

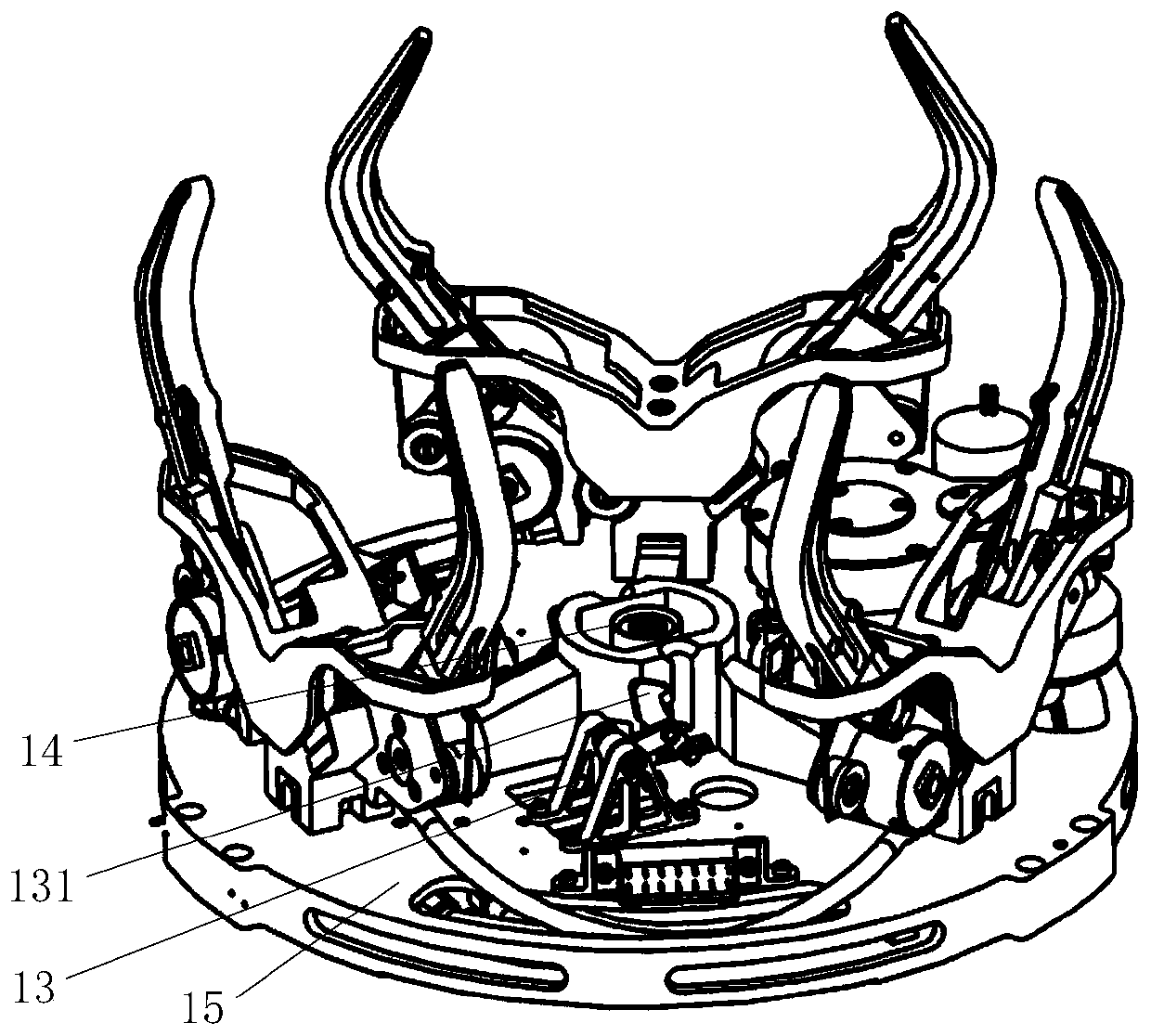

[0023] Such as figure 2 with image 3 As shown, a set of active driving mechanism 11 is installed on one side of the base 15 of the active end 1, three sets of claw mechanisms 12 are uniformly distributed in the circumferential direction, and a set of active end floating electrical connector 14 is installed in the center, and the active end floating electrical connector 14 Two sets of unlocking mechanisms 13 are installed on both sides;

[0024] Such as Figure 4 As shown, a set of slider crank mechanism 16 and four sets of m...

Embodiment 2

[0033] The present invention also provides a docking method of a space docking mechanism, the specific steps are as follows:

[0034] Step 1, capture correction:

[0035] When the active end 1 and the passive end 2 are docked with a certain position deviation, speed and posture, the motor 111 of the active drive mechanism 11 is energized to run, through the gear reducer 112, the crank 162, the connecting rod 163, the slider 164, the lock The tight steel wire rope 125 drives the six lock claws 122 of the three sets of claw mechanisms 12 to retract synchronously. With the retraction of the lock claws 122, the two lock claws 122 of the same set of claw mechanisms 12 form a closed space to complete the active end 1 The capture of the passive end 2; with the further retraction of the locking claw 122, the locking claw 122 collides with the locking handle 202, and finally the locking handle 202 of the passive end 2 is in the position formed by the locking claws 122 and the V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com