Nanometer polypropylene slices and preparation method thereof

A polypropylene chip, polypropylene technology, applied in the direction of one-component polyolefin rayon, rayon manufacturing, fiber chemical characteristics, etc. Melt-blown nonwovens have electrostatic adsorption performance and other issues to achieve the effect of improving filtration performance, super-killing viruses and bacteria, and having safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A nano-polypropylene slice, characterized in that the raw material of the nano-polypropylene slice is composed of the following components by weight percentage: 10% of nano-powder material and 90% of polypropylene slice, wherein the nano-powder material is composed of the following components by weight percentage: Ingredient composition: 93% of nano-scale silicon dioxide, 1.0% of nano-scale titanium dioxide, 3.0% of nano-scale graphene, 1.5% of aluminate coupling agent and 1.5% of stearic acid.

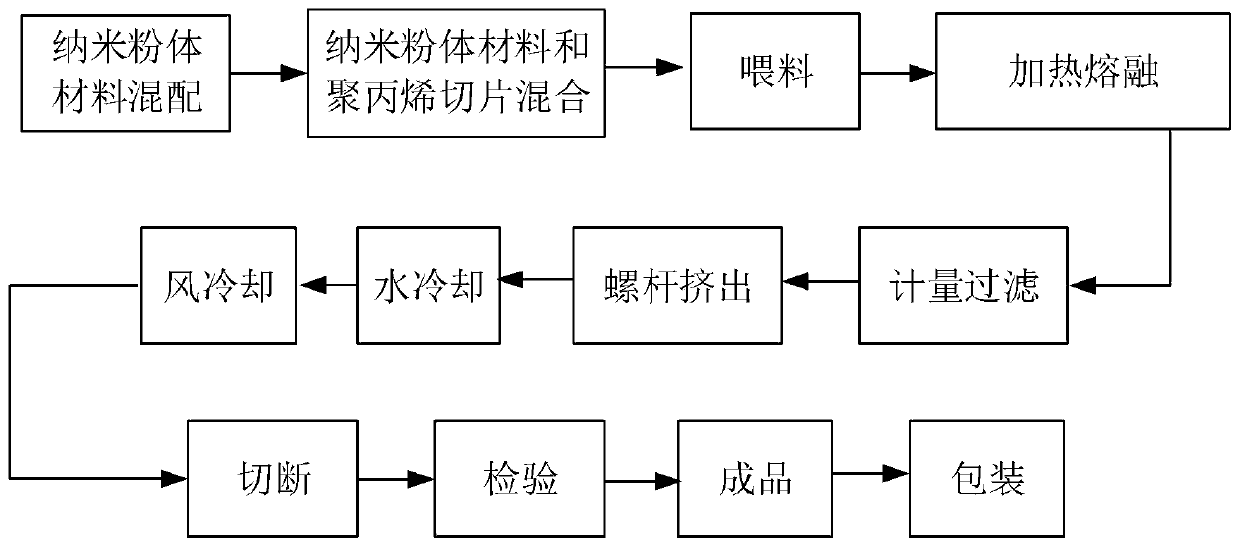

[0023] A method for preparing the nano-polypropylene slice, characterized in that the method comprises the following steps and the following steps are carried out in sequence:

[0024] Step 1. Mixing of nano powder materials

[0025] Weigh nano-scale silicon dioxide, nano-scale titanium dioxide, nano-scale graphene, aluminate coupling agent and stearic acid respectively, and put them into the mixer for mixing. The mixing time is 15 minutes, and the speed of the mixer is 800 rpm...

Embodiment 2

[0029] A nano-polypropylene slice, characterized in that the raw material of the nano-polypropylene slice is composed of the following components by weight percentage: 12% of nano-powder material and 88% of polypropylene slice, wherein the nano-powder material is composed of the following components by weight percentage: Ingredient composition: 94% of nano-scale silicon dioxide, 1.5% of nano-scale titanium dioxide, 2.0% of nano-scale graphene, 1.5% of aluminate coupling agent and 1.0% of stearic acid.

[0030] A method for preparing the nano-polypropylene slice, characterized in that the method comprises the following steps and the following steps are carried out in sequence:

[0031] Step 1. Mixing of nano powder materials

[0032] Weigh nano-scale silicon dioxide, nano-scale titanium dioxide, nano-scale graphene, aluminate coupling agent and stearic acid respectively, and put them into the mixer for mixing. The mixing time is 15 minutes, and the speed of the mixer is 1000 rp...

Embodiment 3

[0036]A nano-polypropylene slice, characterized in that the raw material of the nano-polypropylene slice is composed of the following components by weight percentage: 15% of nano-powder material and 85% of polypropylene slice, wherein the nano-powder material is composed of the following by weight percentage: Ingredient composition: 95% of nano-scale silicon dioxide, 2.0% of nano-scale titanium dioxide, 1.0% of nano-scale graphene, 1.5% of aluminate coupling agent and 0.5% of stearic acid.

[0037] A method for preparing the nano-polypropylene slice, characterized in that the method comprises the following steps and the following steps are carried out in sequence:

[0038] Step 1. Mixing of nano powder materials

[0039] Weigh nano-scale silicon dioxide, nano-scale titanium dioxide, nano-scale graphene, aluminate coupling agent and stearic acid respectively, and put them into a mixer for mixing. The mixing time is 15 minutes, and the speed of the mixer is 1200 rpm. Obtain nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com