Blind hole filling electroplating copper solution and application thereof

A copper electroplating and solution technology, which is applied in the field of blind hole filling electroplating copper solution, can solve the problem that the flatness cannot be fully satisfied, 5-10 microns, and even 15 microns at the maximum, and achieve good flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

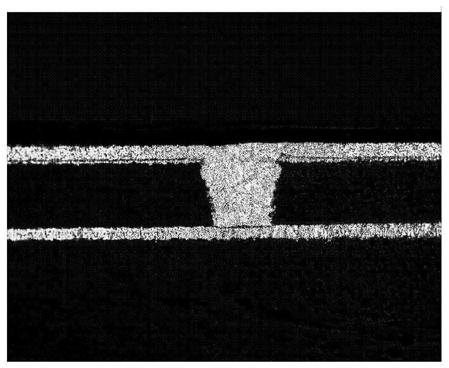

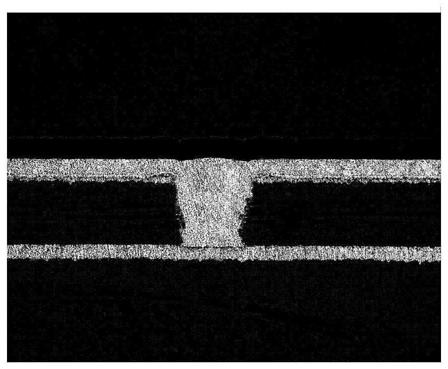

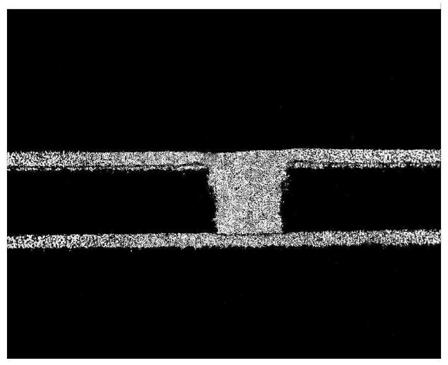

Image

Examples

Embodiment 1

[0036] A copper electroplating solution for blind hole filling, the contents of each component in the copper electroplating solution are as follows: sulfuric acid 40-120g / L, copper sulfate pentahydrate 120-240g / L, chloride ions 40-80ppm, accelerator 0.2-2mL / L, inhibitor 10-30mL / L, leveler 1-10mL / L. Water is the solvent. The accelerator is a 10 g / L aqueous solution of sodium alcoholthiopropane sulfonate or a 10 g / L aqueous solution of sodium polydithiodipropane sulfonate. Described inhibitor is the polyethylene glycol aqueous solution of 10g / L, the polypropylene glycol-polyethylene glycol-polypropylene glycol triblock copolymer aqueous solution of 10g / L, the ethylene oxide-propylene oxide block of 10g / L One of the aqueous solution of the copolymer; the molecular weight of the inhibitor is 4000-10000. The leveling agent is an aqueous solution composed of isonicotinic acid compounds and oligomeric quaternary ammonium compounds in a mass ratio of 1:2-2:1, and the solute concent...

Embodiment 2

[0040] The application of the copper electroplating solution for filling blind vias in the above-mentioned embodiment 1 is applied to filling blind vias of similar substrates. The electroplating process conditions for filling the blind holes of the carrier board are as follows: the current density is 0.5-5A / dm 2 , the temperature is 10-40°C.

[0041] In order to further discuss the feasibility of the present invention, specific test examples based on the technical content, structural features, achieved goals and effects of the present invention will be described in detail with the accompanying drawings.

[0042] Reagent pre-preparation

[0043] For the convenience of testing, the accelerator, inhibitor, and leveling agent were respectively prepared into aqueous solutions with a solute content of 10 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com