A method for dealing with tunnel collapse by using a top-connected shield support

A technology for shields and tunnels, which is applied in the field of tunnel collapse using top-connected shield supports, which can solve problems such as the inability to apply active support on the surface of the collapsed cavity, insufficient lifting height of single hydraulic props, and cylinder explosion, so as to avoid demolition operation, avoid cylinder explosion accidents, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

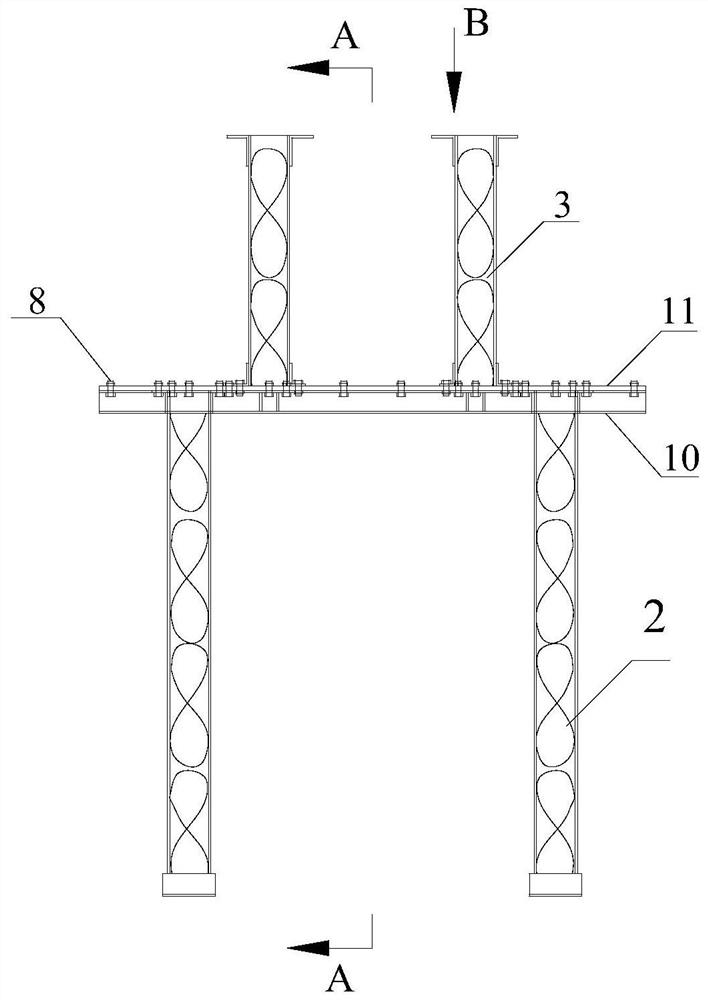

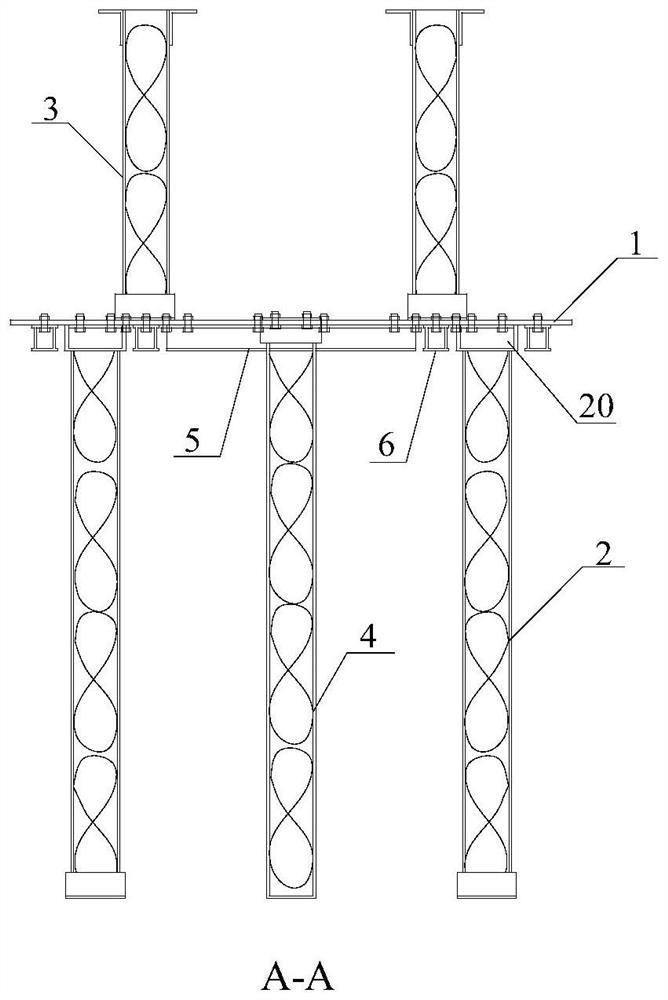

[0045] combine Figure 1 to Figure 14 As shown, a method for dealing with tunnel collapse using a top-connected shield support provided by the present invention is implemented in the following manner.

[0046] A method for dealing with tunnel collapse by using a roof-connected shield support, which is mainly applied to the initial collapse in the tunnel, and the cavity surface of the collapse cavity 28 is relatively flat, and it is easier to deal with the collapse of the roof. The specific steps include:

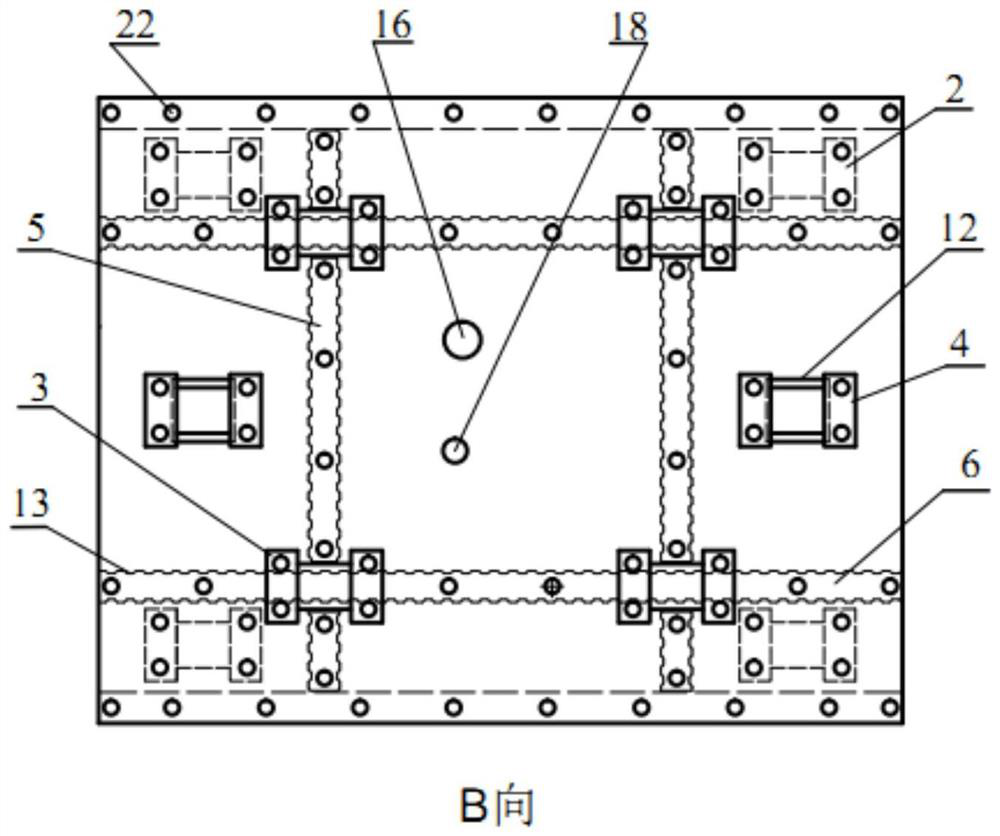

[0047] Step 1. Fix the column 2, the fixed support column 3, the movable support column 4, the beam 5 and the longitudinal beam on the shield plate 1 to form a combined bracket, wherein the upper connecting plate of the movable support column 4 is fixed on the upper surface of the shield plate 11.

[0048] Specifically, first set guide holes 12, reserved concrete holes 16 and reserved air holes 18 at appropriate positions on the selected shield plate 1. The shield plate 1 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com