Storage battery plate group processing production line

A storage battery and production line technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve problems such as low work efficiency, poor automation, and inability to realize automatic input and output of batteries, and achieve the degree of automation High, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

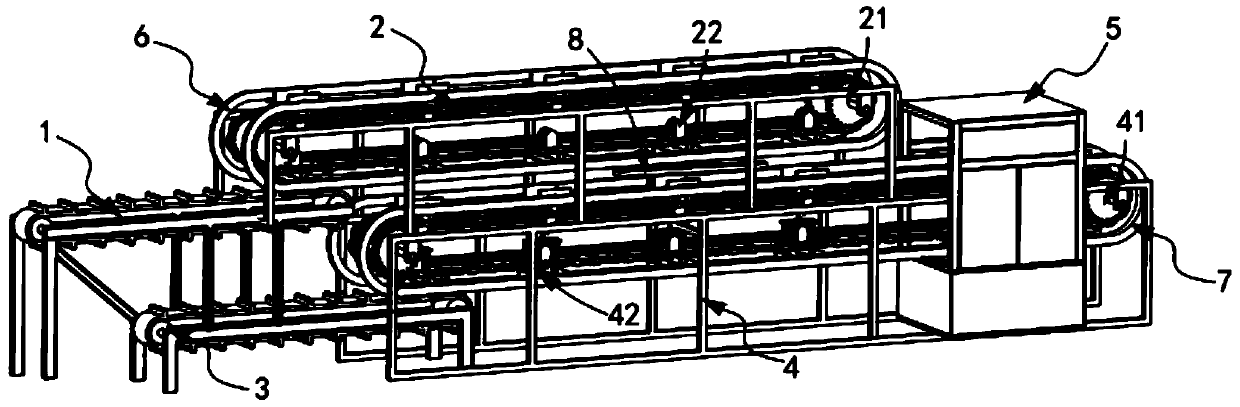

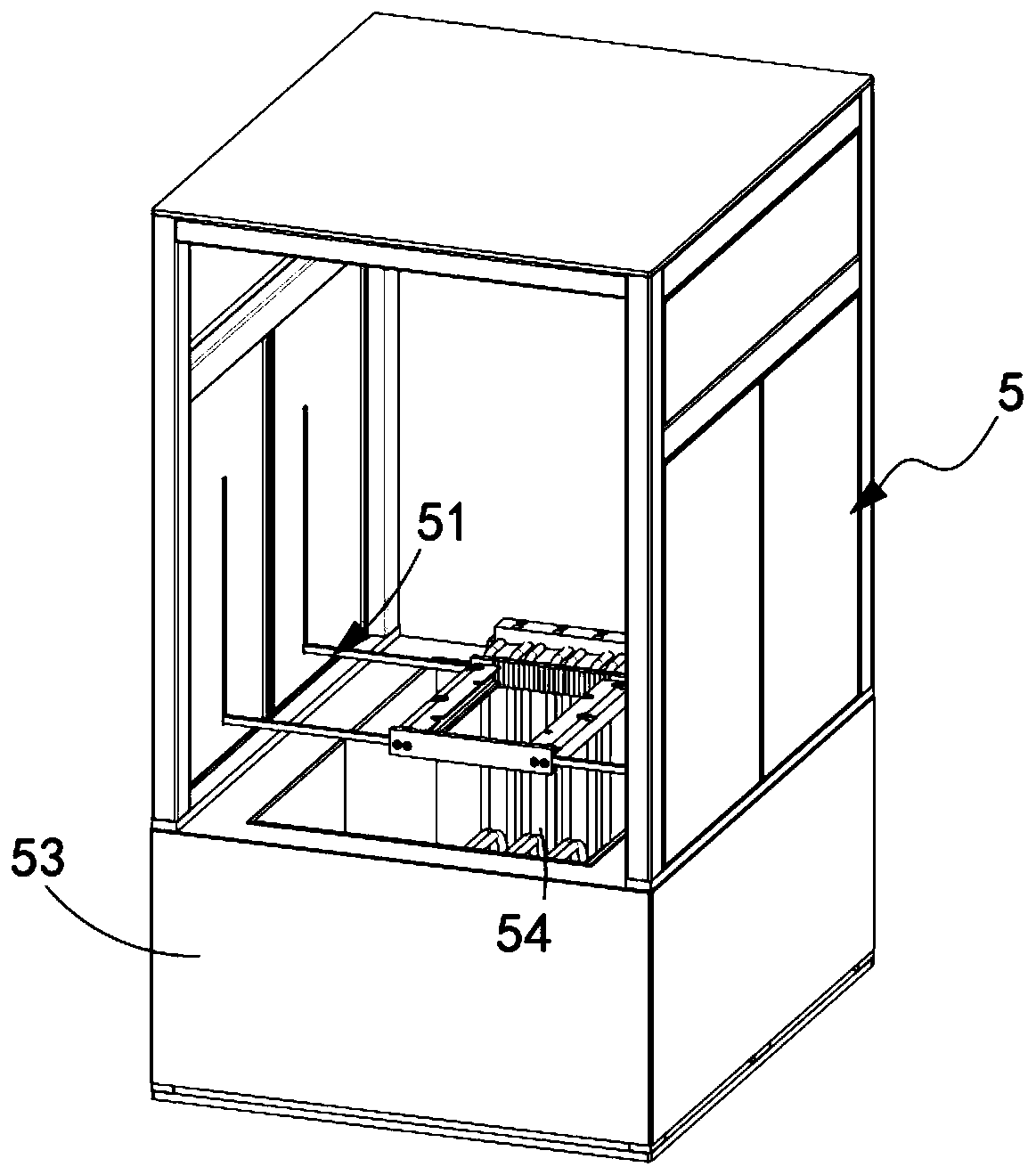

[0052] Such as figure 1 , figure 2 with image 3 As shown, a battery pole group processing production line includes:

[0053] The pole group transmission mechanism 1, the pole group transmission mechanism 1 is used to sequentially transport several groups of pole groups 10 backward;

[0054] The pole group clamping mechanism 2, the pole group clamping mechanism 2 is located above the pole group transmission mechanism 1, and it includes a first transmission assembly 21 and a number of equidistant along the transmission direction of the first transmission assembly 21. A first tightening component 22 assembled and installed on the first conveying component 21;

[0055] A shell transmission mechanism 3, which is located below the pole group clamping mechanism 2, and is used to sequentially transport several groups of battery shells 20 backwards;

[0056] The shell clamping mechanism 4, the shell clamping mechanism 4 is located above the shell transmission mechanism 3, it incl...

Embodiment 2

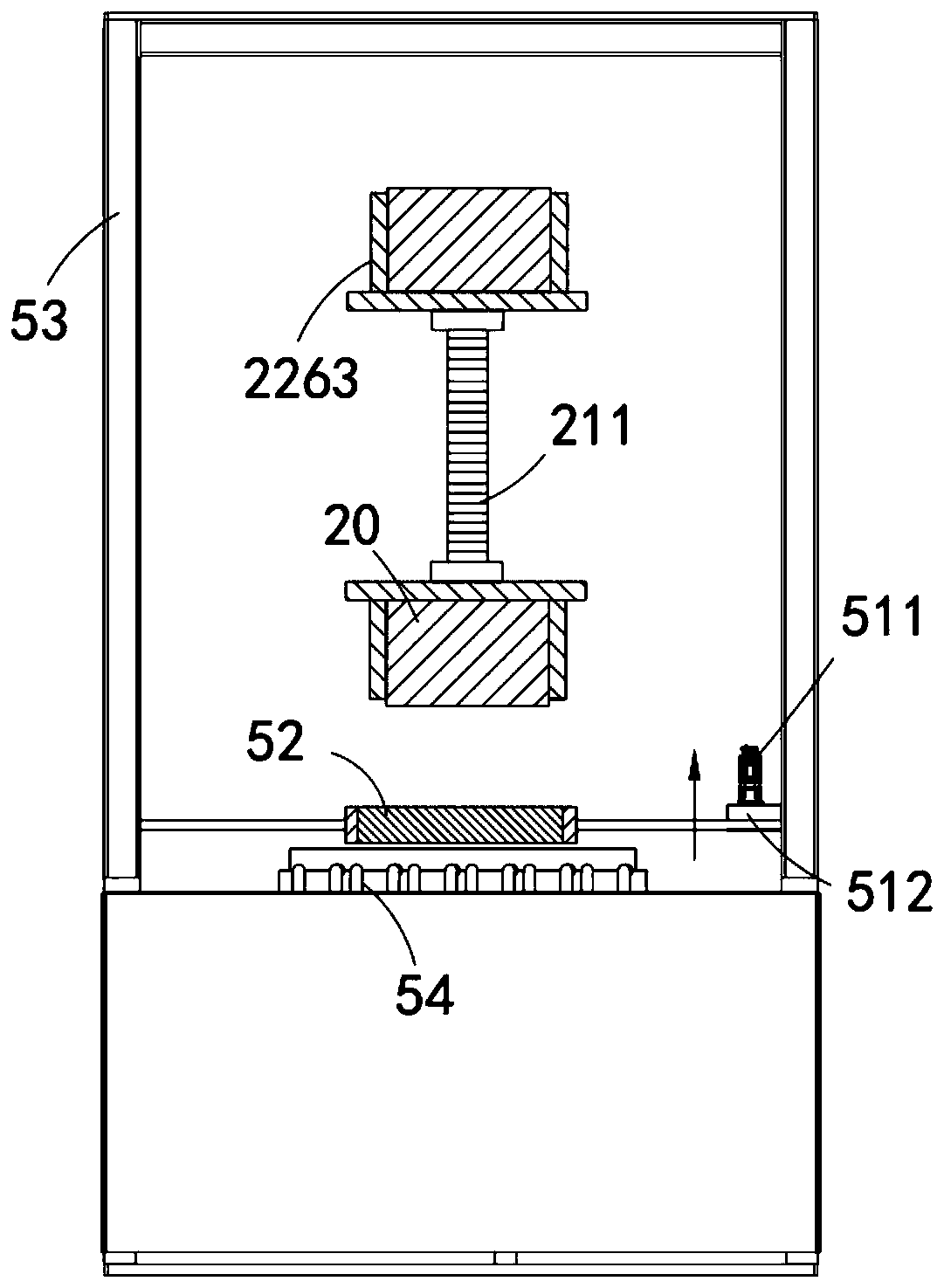

[0082] Such as Figure 7-Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0083] further, such as Figure 7-Figure 10As shown, the first guide assembly 6 includes two sets of guide rails a61 installed on the machine tool 211, and the distance between the two sets of guide rails a61 forms a clamping portion a62 and a limiting portion a63. The distance of the holding portion a62 from the input end to the output end decreases gradually, and the distance of the limiting portion a63 from the input end to the output end remains constant.

[0084] In this embodiment, by setting the control member 227 to cooperate with the guidance of the guide track a61, the two sets of splints 2263 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com