Manufacturing method of permanent magnet motor rotor

A technology for permanent magnet motors and manufacturing methods, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., and can solve the problem that epoxy potting adhesives cannot meet the requirements of high temperature resistance, mass production of motors, Affect the reliability of the motor rotor and other issues to achieve the effect of avoiding air bubbles and holes, improving potting efficiency, and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the step (3), in the process of potting, the potting glue 15 used is an addition-type silicone rubber; the preparation method of the potting glue 15 comprises: adding a two-component main agent of the addition-type silicone rubber and The accelerator is mixed, stirred evenly, and degassed for 10-15 minutes under the condition that the vacuum degree is not higher than 100Pa, and the product is obtained. The two-component main agent and accelerator of the addition type silicone rubber are common in the field.

[0048] In the step (3), the potting includes: stirring the mixed potting compound 15 evenly, degassing under vacuum conditions, and then injecting into the gap between the permanent magnet 7 and the rotor punch 4 .

[0049] Before the potting glue 15 is injected into the gap between the permanent magnet 7 and the rotor punch 4, it also includes preheating the semi-finished product; the preheating condition is to preheat at 100-110° C. for 1-1.5 hours.

[0050] W...

Embodiment 1

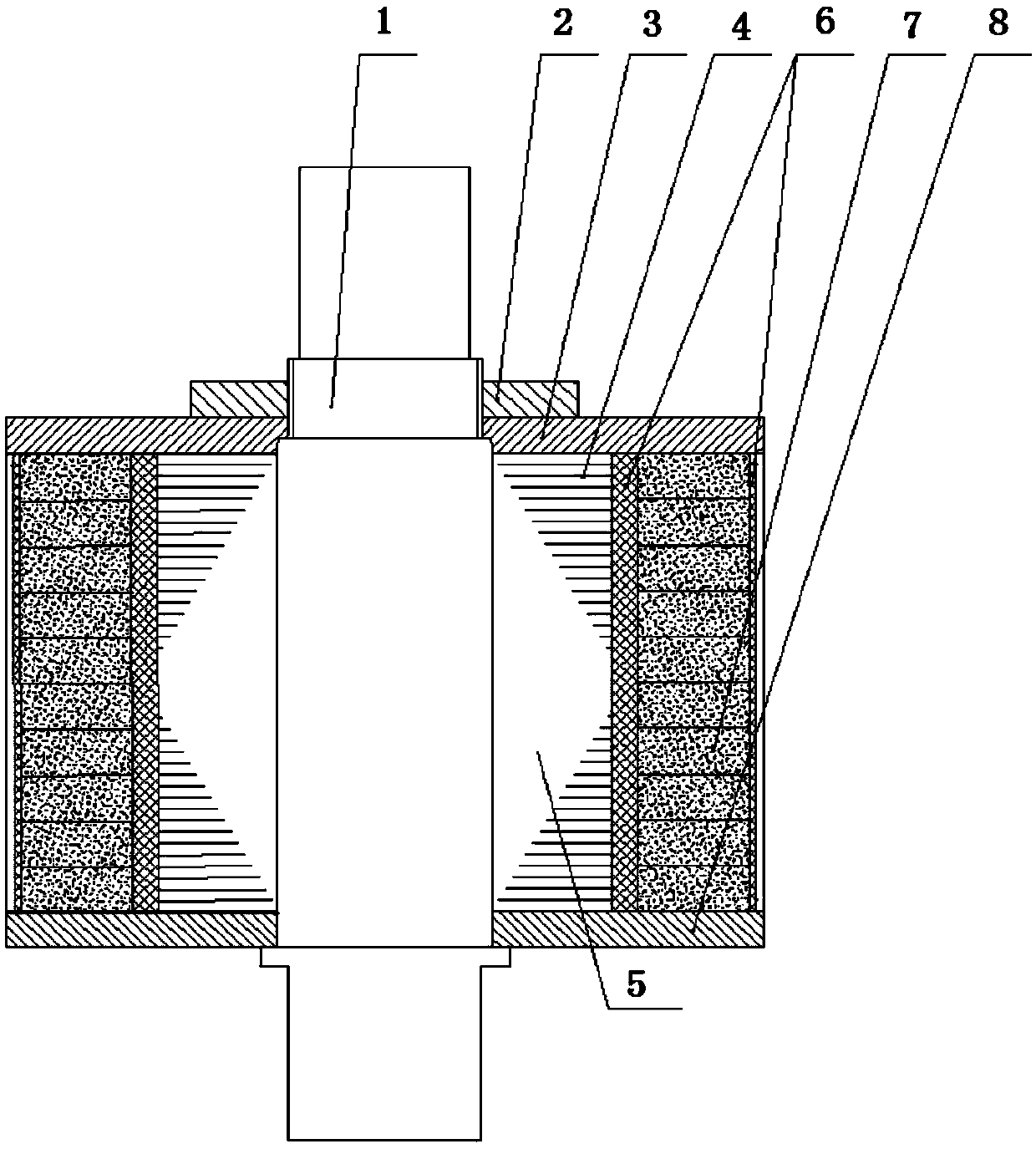

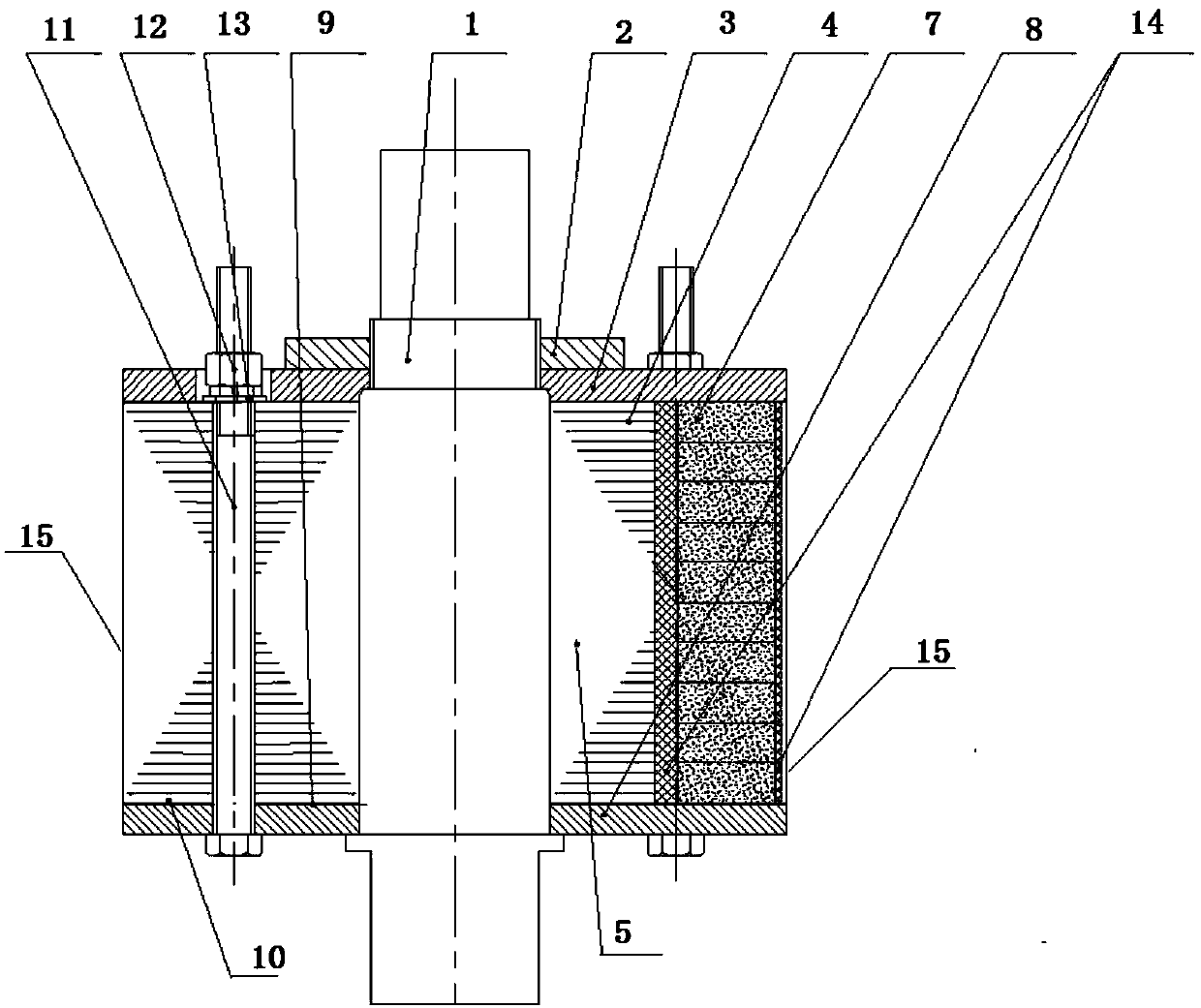

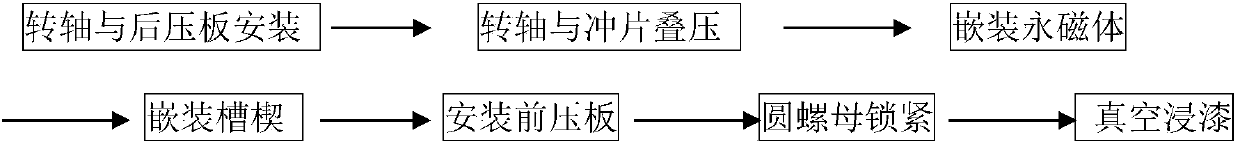

[0053] A manufacturing method of the permanent magnet motor rotor of the present invention, the assembly schematic diagram of the permanent magnet motor rotor is as follows figure 2 As shown, the process flow is as follows:

[0054]

[0055] Concrete manufacturing method comprises the steps:

[0056] (1) cutting the polyimide film 9 according to the size of the first pressing plate 8, leaving holes corresponding to the installation holes of the first pressing plate 8 on the polyimide film 9 obtained by cutting; Both sides of the imide film 9 are coated with the first high-temperature-resistant silicone grease layer 10, the coating thickness is 0.1-0.2mm, and then the polyimide film 9 is pasted on the surface of the first pressure plate 8, and the surface of the polyimide film 9 is The reserved installation holes are aligned with the installation holes of the first pressure plate 8, so that they form a whole and constitute the first assembly.

[0057] (2) After inserting ...

Embodiment 2

[0064] A method for manufacturing a permanent magnet motor rotor of the present invention, the steps are basically the same as the steps in Example 1, and the differences are as follows:

[0065] The structure of the first assembly in step (1) is different. The step (1) of this embodiment is to coat a Teflon coating on one surface (ie, the upper surface) of the first pressing plate 8 to form the first assembly, that is, the present embodiment Example A Teflon coating is used to replace the polyimide film 9 whose surface is coated with the first high-temperature-resistant silicone grease layer 10 in Example 1, and the thickness of the Teflon coating is 20-30 μm.

[0066] In step (2), in this embodiment, the second high-temperature-resistant silicone grease layer 14 is replaced by brushing Teflon coating on the peripheral surface of the rotor core, and the Teflon coating thickness is 20-30 μm.

[0067] In step (1), the polyimide film 9 of the first high-temperature-resistant sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com