Photosensitive composite bio-ink for 3D printing and preparation method thereof

A bio-ink and 3D printing technology, applied in the field of biomaterials and cell-containing hydrogels, can solve the problems of low viscosity, large amount of modifiers, and limited cell proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

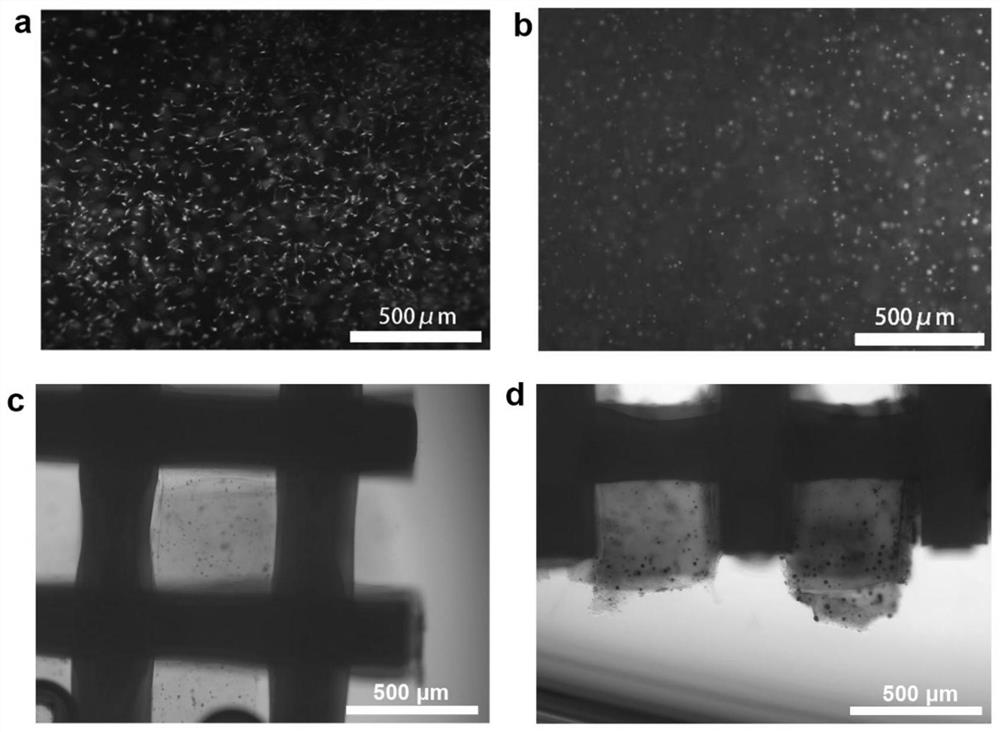

Image

Examples

Embodiment 1

[0037] The raw material of the collagen solution is self-extracted bovine Achilles tendon collagen, which is obtained through degreasing, enzymatic hydrolysis, salting out and other steps. The bovine Achilles tendon glue is dissolved in 0.1mol / L acetic acid solution to prepare an acidic collagen solution of 6mg / mL .

[0038] Mix 8.09 mL of the above collagen solution, 1 mL of 10-fold concentration PBS, 0.81 mL of 1 mol / L sodium hydroxide, and 0.1 mL of 1 mg / mL phenol red. At this point, the solution was poured into 10 times the volume of 0.01 mol / L PBS solution, and magnetically stirred in a water bath at 37° C. for 1 hour at a stirring speed of 1000 rpm. The above solution was centrifuged at 10000 g for 1 h, the supernatant was discarded, and the precipitate was collagen fibers. The above steps are performed aseptically.

[0039] Adopt improved synthesis method of photosensitive gelatin: weigh 10g of gelatin, dissolve in 100mL of PBS, heat to 60°C, stir until completely disso...

Embodiment 2

[0043] The raw material for the preparation of the collagen solution was self-extracted bovine Achilles tendon collagen. After degreasing, enzymatic hydrolysis, salting out and other steps, an 8mg / mL acidic collagen solution was obtained. The solvent was acetic acid solution with a concentration of 0.1mol / L. Mix 8.09 mL of the above collagen solution, 1 mL of 10-fold concentration PBS, 0.81 mL of 1 mol / L sodium hydroxide, and 0.1 mL of 1 mg / mL phenol red. At this time, the solution was poured into 5 times volume of 2 times concentration PBS solution, and magnetically stirred in a water bath at 25° C. for 2 hours at a stirring speed of 1000 rpm. The above solution was centrifuged at 10000 g for 1 h, the supernatant was discarded, and the precipitate was collagen fibers. The above steps are performed aseptically. A modified photosensitive gelatin synthesis method was used.

[0044] Weigh 10g of gelatin, dissolve it in 100mL of PBS, heat to 60°C, stir until completely dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com