Touring car compartment rotational moulding manufacturing process

A production process and technology for carriages, which are applied in household components, applications, coatings, etc., can solve the problems of heavy weight, strength, rigidity, poor sound insulation and heat insulation performance, etc., and achieve the effects of high speed, good sound insulation function and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

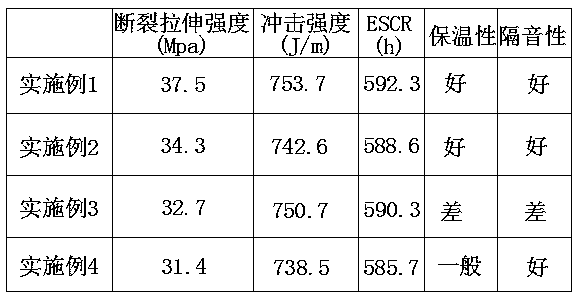

Examples

Embodiment 1

[0028] A manufacturing process of rotational molding of a caravan compartment, comprising the following steps:

[0029] S1. Installation: Take the mold used to produce the caravan, and install the mold on the molding machine;

[0030] S2. Preheating: heating the inner film of the mould, and preheating the inner wall of the mould;

[0031] S3. One-time feeding: inject PE material into the mold and close the mold;

[0032] S4. Heating and melting: through the heating of the mold and the vertical and horizontal rolling and rotation, the material is evenly filled in the cavity of the mold by its own gravity and centrifugal force and melted;

[0033] S5. Secondary feeding: open the mold, add thermal insulation and sound insulation fillers to the middle of the rotomolded parts, close the mold, and continue heating to the softening point of the fillers;

[0034] S6, molding, continue to increase the temperature of the heating chamber, so that the filler with heat preservation and s...

Embodiment 2

[0042] A manufacturing process of rotational molding of a caravan compartment, comprising the following steps:

[0043] S1. Installation: Take the mold used to produce the caravan, and install the mold on the molding machine;

[0044] S2. One-time feeding: inject PE material into the mold and close the mold;

[0045] S3. Heating and melting: through the heating of the mold and the vertical and horizontal rolling and rotation, the material is evenly filled in the cavity of the mold by its own gravity and centrifugal force and melted;

[0046] S4. Secondary feeding: open the mold, add thermal insulation and sound insulation fillers to the middle of the rotomolded parts, close the mold, and continue heating to the softening point of the fillers;

[0047] S5 molding, continue to increase the temperature of the heating chamber, so that the thermal insulation and sound insulation fillers are melted and foamed to fill the inner cavity of the product;

[0048] S6. Cooling and demoul...

Embodiment 3

[0055] A manufacturing process of rotational molding of a caravan compartment, comprising the following steps:

[0056] S1. Installation: Take the mold used to produce the caravan, and install the mold on the molding machine;

[0057] S2. Preheating: heating the inner film of the mould, and preheating the inner wall of the mould;

[0058] S3. One-time feeding: inject PE material into the mold and close the mold;

[0059] S4. Heating and melting: through the heating of the mold and the vertical and horizontal rolling and rotation, the material is evenly filled in the cavity of the mold by its own gravity and centrifugal force and melted;

[0060] S5. Cooling and demoulding, transfer the mold to the cooling chamber, first air cooling and then water cooling, and after cooling, remove the product from the mold.

[0061] PE material needs to be processed before it is added to the mold. The steps are as follows:

[0062] A. After washing the PE material required for processing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com