Portable electric four-wheeler chassis

An electric four-wheeled vehicle, portable technology, applied in the direction of electric power unit, vehicle seat, power unit, etc., can solve the problems of low strength and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

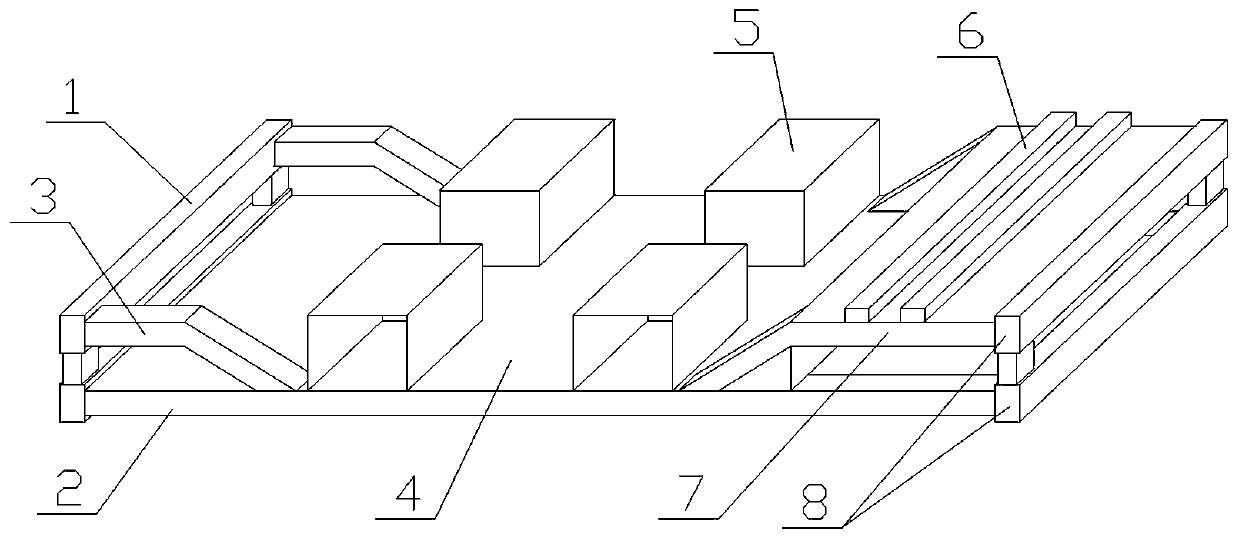

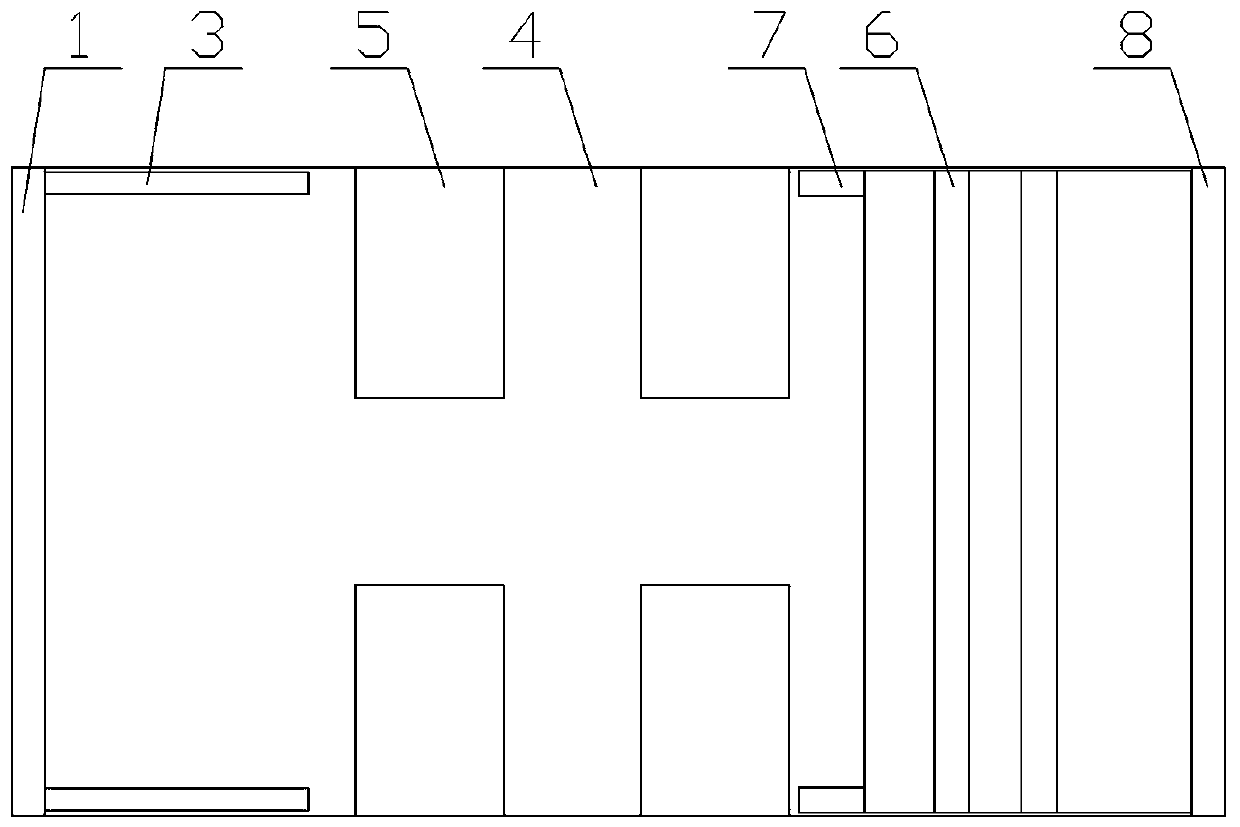

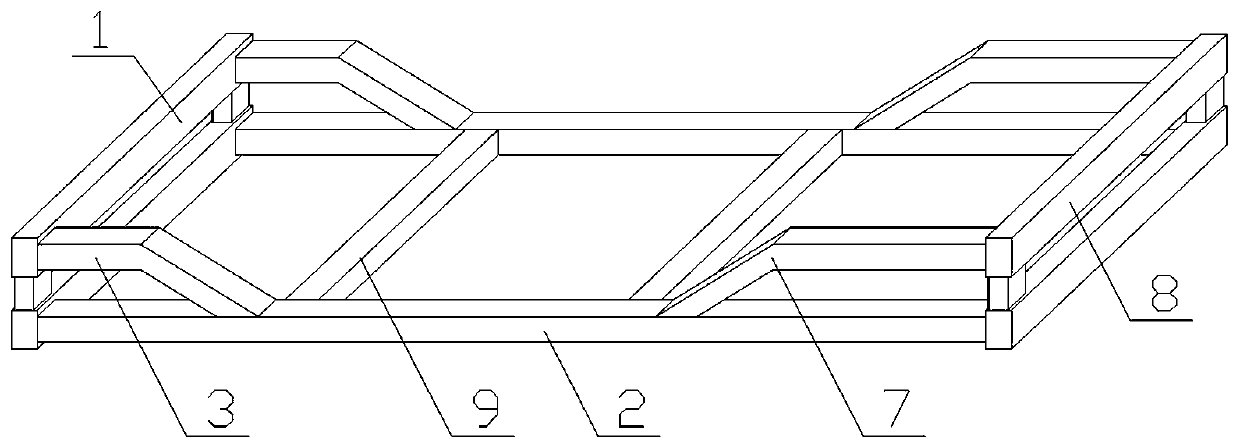

[0026] according to Figure 1-Figure 4 , a portable electric four-wheel vehicle chassis, which includes two symmetrically distributed longitudinal beams 2; the front and rear sides of the longitudinal beams are respectively connected vertically by the front beam 1 and the rear beam 8; the front beam and the rear beam It is in the shape of a rectangular frame, and the longitudinal beam is connected to the lower part of the front cross beam and the rear cross beam; the front support arm 3 and the rear support arm 7 are arranged on the longitudinal beam; one end of the front support arm and the rear support arm is respectively connected to the front cross beam and the upper part of the rear beam, and the other end is bent downward to connect with the longitudinal beam; the panel layer 4 is laid on the longitudinal beam and the rear support arm; the battery box 5 is arranged on the panel layer corresponding to the first two rows of seats; The battery box extends to the stringer wi...

Embodiment 2

[0035] The present invention improves the material and technology of the longitudinal beam, front cross beam, rear cross beam, cross brace, front support arm and rear support arm, so as to improve its comprehensive performance and reduce its weight. It is prepared by the following process:

[0036] First, add aluminum into the melting furnace, control the temperature between 700°C and 750°C to make it completely melted, and stir the aluminum liquid evenly;

[0037] Add AlMg20 accounting for 30% by weight of aluminum, AlTi5 of 10% by weight, AlNi10 of 5% by weight and AlCu50 of 1% by weight to the aluminum liquid in sequence, refining for 30 minutes, and after the refining is completed, all the slag in the aluminum liquid is completely Float to the surface and clean up the slag;

[0038] The alloy liquid is released from the furnace, cooled to 680°C, slowly poured into the sprue until it fills the entire mold cavity, cooled naturally, and then shelled to obtain a rough casting;...

Embodiment 3

[0052] The aluminum alloy property test of embodiment 2 of the present invention and comparative example 1-3:

[0053] The specific performance parameters are shown in Table 1:

[0054] Table 1

[0055] group Density g / cm 3

[0056] 2. Increasing the amount of magnesium will reduce the specific gravity of the alloy and improve the machinability, but adding too much magnesium will reduce the yield strength and hardness. Therefore, it is more important to choose the appropriate amount of magnesium, and set the amount of AiMg20 Accounting for 5%, 10%, 20%, 30%, 40%, 50% of aluminum respectively, such as Figure 5 As shown, with the increase of AiMg20, the yield strength decreases, but the decrease is small. When it increases to 40%, the yield strength decreases significantly. Therefore, it is more appropriate to choose the addition amount of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com