Preparation method of AC foaming agent

A technology of foaming agent and crystal seed is applied in the field of preparation of AC foaming agent, which can solve the problems of rough surface of particles, single variety, unable to meet market demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A preparation method of AC blowing agent, comprising the following steps:

[0051] (1). Grinding the biurea raw material: filter and wash the synthesized biurea, and ultrafinely pulverize the biurea to a particle size of 4-8 μm;

[0052] (2). Preparation of biurea slurry: Add water to the pulverized biurea to make a biurea slurry containing 20-40% of biurea, and then add biurea with a mass ratio of 0.3-10%. Oxidation aids;

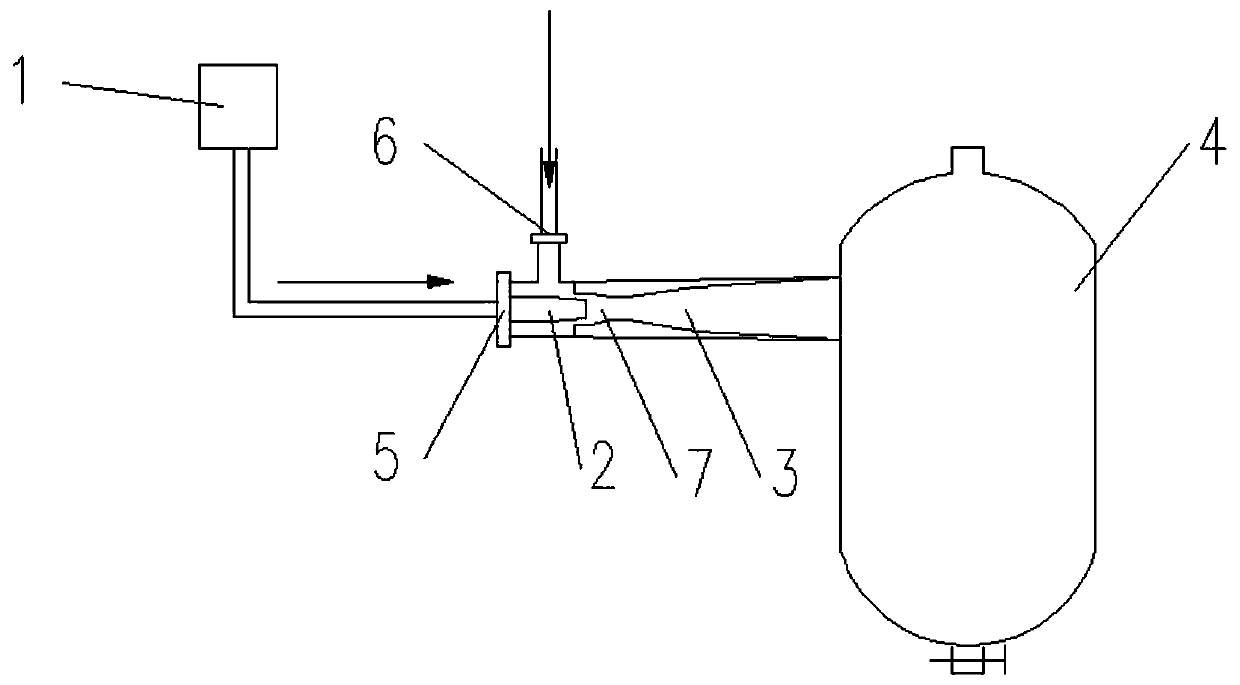

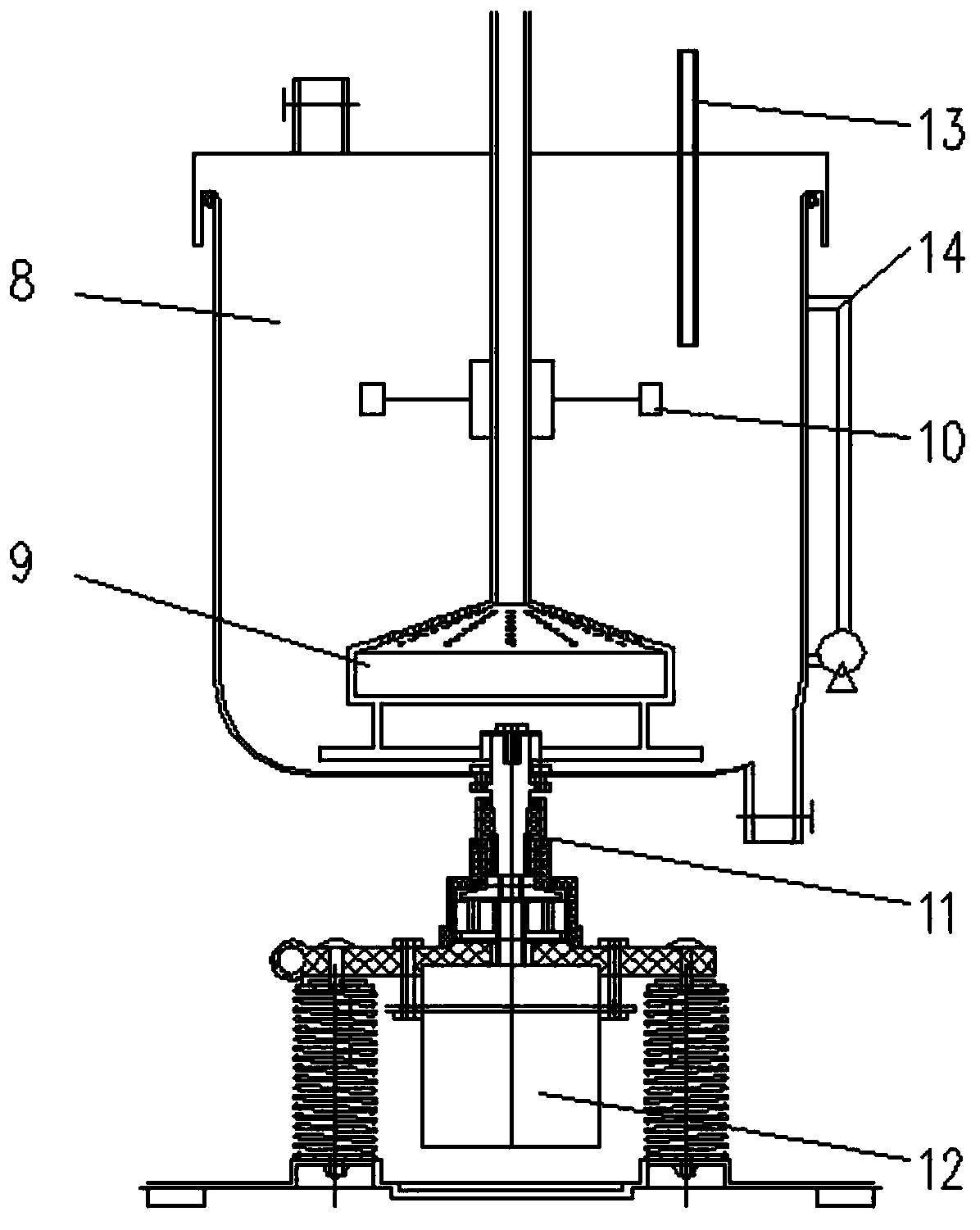

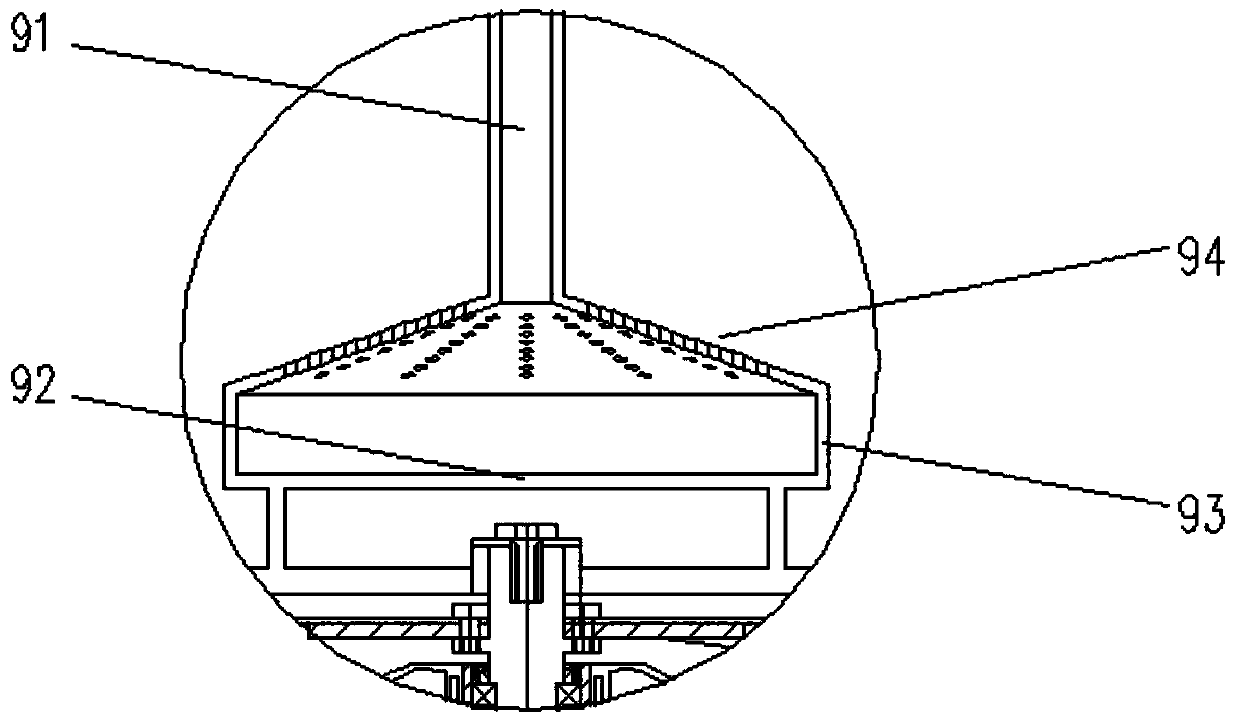

[0053] (3). Generation of seed crystals: The configured 3% to 10% biurea slurry is sprayed at high speed through a liquid injection device, and enters the injection reaction device from an inlet of the injection reaction device, and forms in the injection reaction device. Vacuum, the chlorine gas is sucked into the jet reaction device from another inlet of the jet reaction device, and the two are vigorously mixed in the jet reaction device to form a large number of AC blowing agent seeds in an instant, and the reaction mixture with AC blowing agent...

Embodiment 1

[0066] (1). Grinding the biurea raw material: filter and wash the synthesized biurea, and ultrafinely pulverize the biurea to a particle size of 4-8 μm;

[0067] (2). Preparation of biurea slurry: add water to the pulverized biurea to form a biurea slurry containing 20% biurea, and then add an oxidation aid with a mass ratio of 5% biurea;

[0068] (3). Generation of crystal seeds: the configured 10% biurea slurry is ejected at high speed through a liquid injection device, and enters the injection reaction device from an inlet of the injection reaction device, and a vacuum is formed in the injection reaction device. Chlorine gas is sucked into the jet reaction device from another inlet of the jet reaction device, and the two are violently mixed in the jet reaction device to form a large amount of AC blowing agent crystal seeds instantly, and collect the reaction mixture with the AC blowing agent crystal seeds;

[0069] (4). Mix evenly: add the remaining biurea slurry and the ...

Embodiment 2

[0073] (1). Grinding the biurea raw material: filter and wash the synthesized biurea, and ultrafinely pulverize the biurea to a particle size of 4-8 μm;

[0074] (2). Preparation of biurea slurry: add water to the pulverized biurea to form a biurea slurry containing 35% biurea, and then add an oxidation aid with a mass ratio of 10% biurea;

[0075] (3). Generation of crystal seeds: the configured 10% biurea slurry is ejected at high speed through a liquid injection device, and enters the injection reaction device from an inlet of the injection reaction device, and a vacuum is formed in the injection reaction device. Chlorine gas is sucked into the jet reaction device from another inlet of the jet reaction device, and the two are violently mixed in the jet reaction device to form a large amount of AC blowing agent crystal seeds instantly, and collect the reaction mixture with the AC blowing agent crystal seeds;

[0076] (4). Mix evenly: add the remaining biurea slurry and the A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com