Gas cylinder static evaporation rate detection device and method

A detection device and detection method technology, which are applied to measurement devices, container filling methods, container discharge methods, etc., can solve the problems of long time, cumbersome data acquisition equipment, and the inability of vehicle-mounted gas cylinders to be disassembled and assembled at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

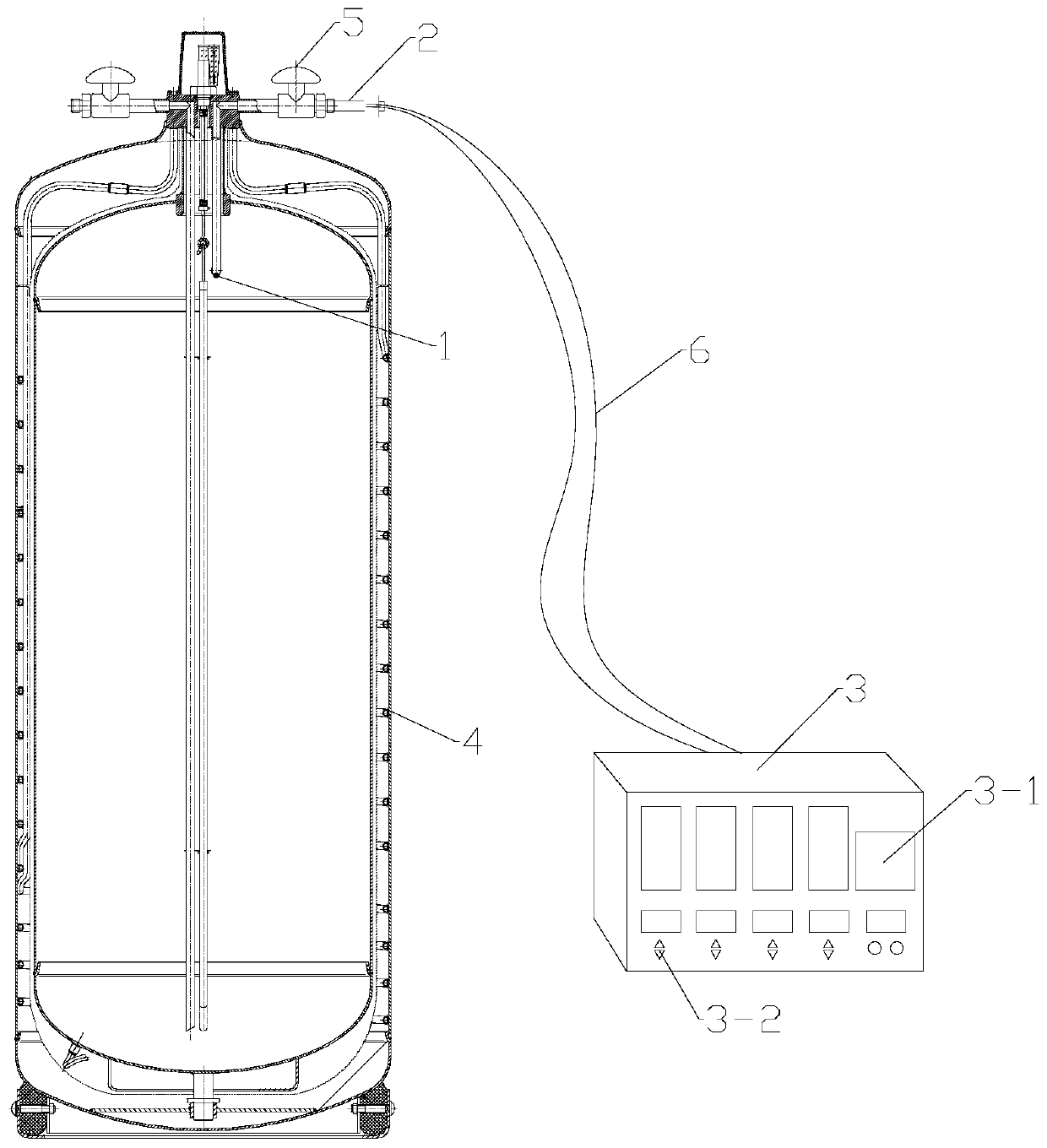

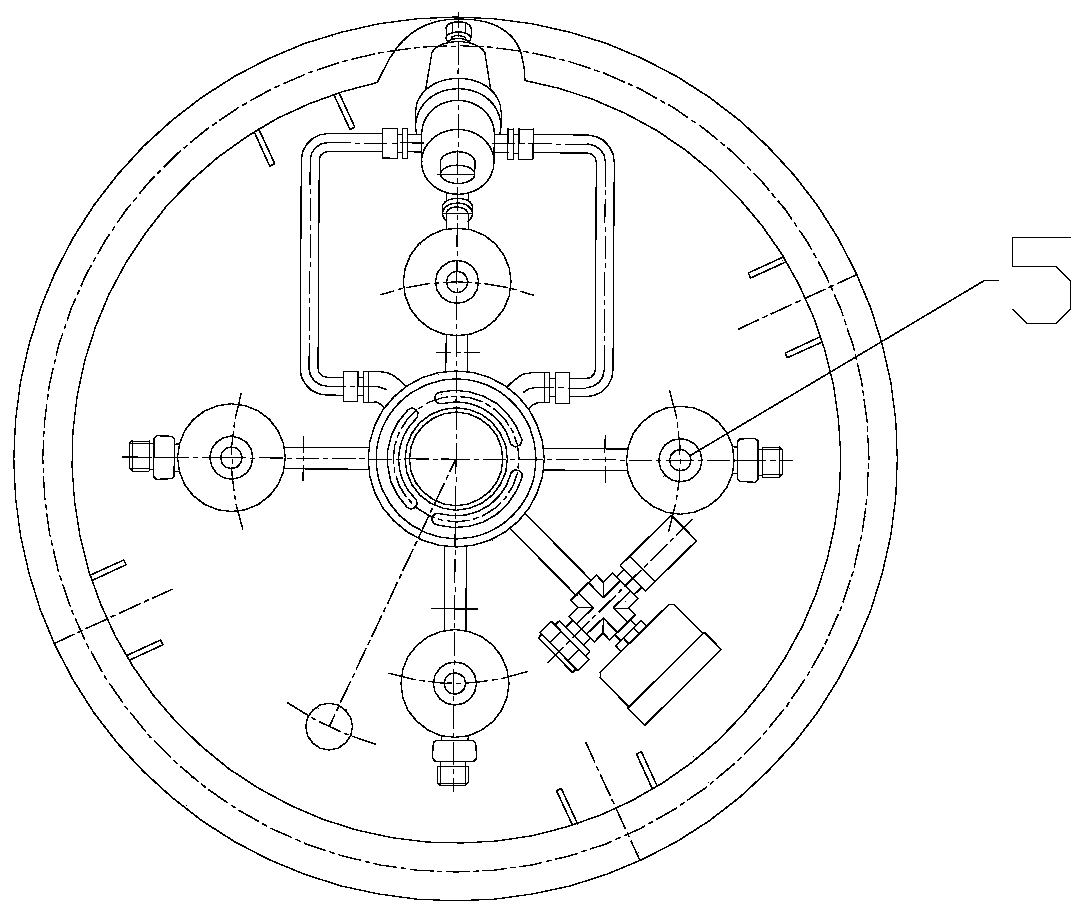

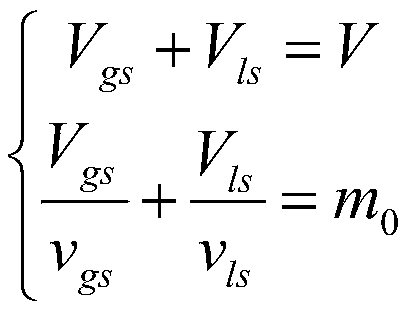

[0068] Such as figure 1 with figure 2 As shown, a gas cylinder static evaporation rate detection device includes a temperature collector, a pressure collector, and an integrated tester; the temperature collector is connected to the inlet of the gas cylinder vent valve pipeline, and the range of the temperature collector is -200 ~150°C, with a temperature sensor or thermocouple with a tolerance of ±1°C, the temperature collector is used to measure the temperature at the inlet of the gas cylinder vent valve pipeline; the pressure collector is connected to the outlet of the gas cylinder vent valve, the pressure The collector selects a pressure sensor or pressure gauge with a range of 0-4MPa and an accuracy of 0.01MPa. The pressure collector is used to measure the pressure value at the outlet of the vent valve of the gas cylinder; there are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com