Anti-blue-ray sterilization anti-glare protection sheet for display screen

An anti-blue light and anti-glare technology, which is applied in the fields of optical filters, ion implantation plating, disinfection, etc., can solve the problems of single function of protective film and inability to meet the needs of protective film with multiple protective functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

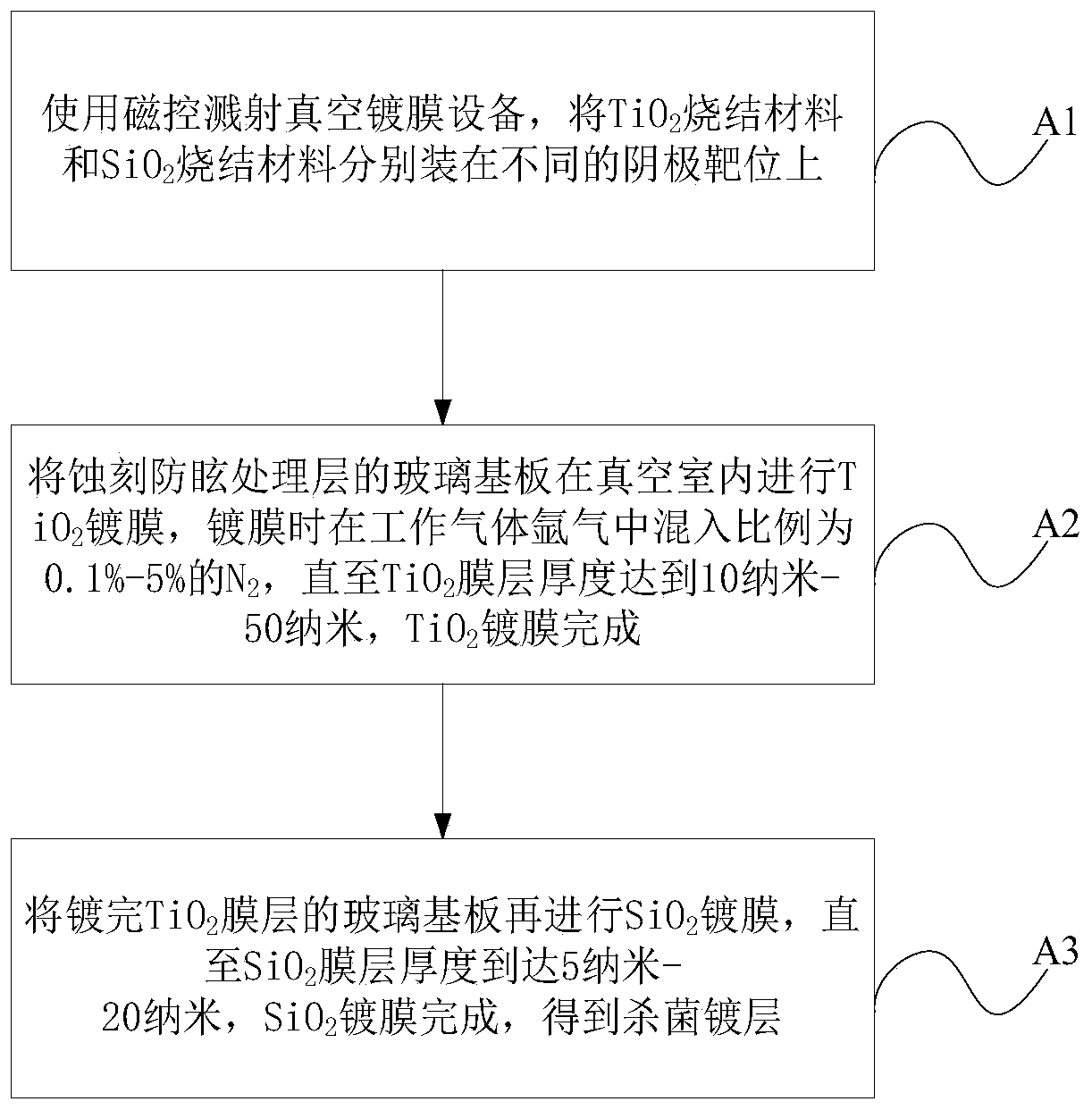

[0049] In a specific example, see the attached image 3 , the preparation method of bactericidal coating 1 comprises:

[0050] A1: Using magnetron sputtering vacuum coating equipment, TiO2 Sintered material and SiO 2 The sintered materials are installed on different cathode targets respectively;

[0051] A2: The glass substrate of the anti-glare treatment layer is etched with TiO in a vacuum chamber 2 Coating, mixing 0.1%-5% N in the working gas argon during coating 2 , up to TiO 2 The film thickness reaches 10nm-50nm, TiO 2 Coating completed;

[0052] A3: TiO will be plated 2 The glass substrate of the film layer is then subjected to SiO 2 coating, up to SiO 2 The thickness of the film layer reaches 5nm-20nm, SiO 2 After the coating is completed, a bactericidal coating is obtained.

[0053] Specifically, the light transmittance of the anti-blue light coating 4 to the wavelength range of 380-450nm is less than 50%, and the light transmittance of the anti-blue light c...

Embodiment 1

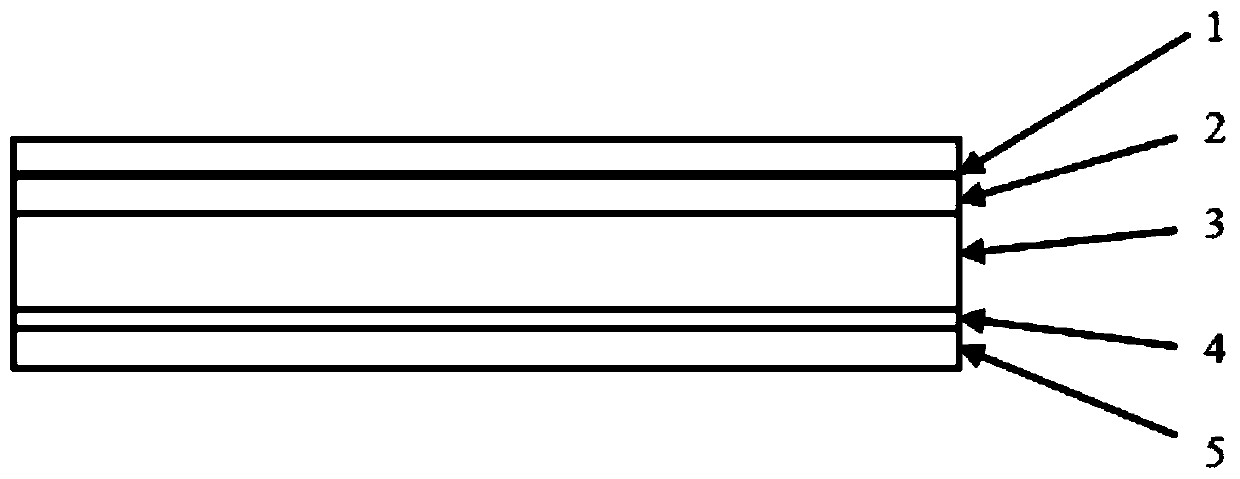

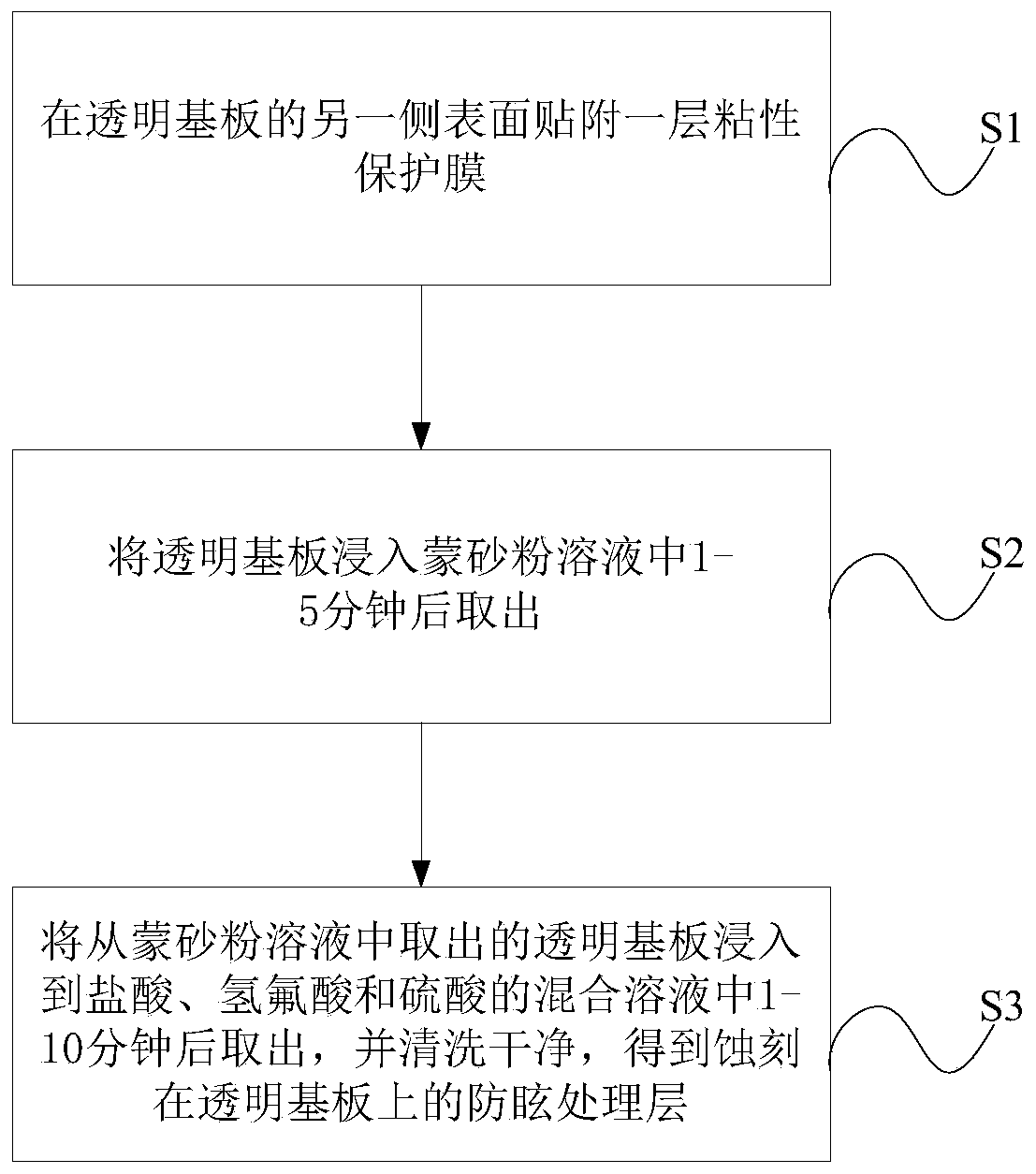

[0061] The anti-blue light sterilization and anti-glare protection sheet used for the display screen in this embodiment adopts the above-mentioned figure 1 In the layer structure shown, the transparent substrate is made of soda-lime glass, and the etching process of the anti-glare treatment layer is as follows:

[0062] Step 1: Attach a layer of adhesive protective film on the other side of the transparent substrate;

[0063] Step 2: Immerse the transparent substrate in the frosting powder solution for 1 minute and take it out;

[0064] S3: Immerse the transparent substrate taken out of the frosting powder solution into a mixed solution of hydrochloric acid, hydrofluoric acid and sulfuric acid for 1 minute, take it out, and clean it to obtain an anti-glare treatment layer etched on the transparent substrate.

[0065] The preparation method of bactericidal coating comprises:

[0066] Step 1: Using magnetron sputtering vacuum coating equipment, TiO 2 Sintered material and SiO...

Embodiment 2

[0070] The anti-blue light sterilization and anti-glare protection sheet used for the display screen in this embodiment adopts the above-mentioned figure 1 In the shown layer structure, wherein the transparent substrate is high-alumina glass, the etching process of the anti-glare treatment layer 2 specifically includes the following steps:

[0071] Step 1: Attach a layer of adhesive protective film on the other side of the transparent substrate;

[0072] Step 2: Immerse the transparent substrate in the frosting powder solution for 3 minutes and take it out;

[0073] Step 3: Immerse the transparent substrate taken out of the frosting powder solution into a mixed solution of hydrochloric acid, hydrofluoric acid and sulfuric acid for 5 minutes, take it out, and clean it to obtain an anti-glare treatment layer etched on the transparent substrate.

[0074] The preparation method of bactericidal coating comprises:

[0075] Step 1: Using magnetron sputtering vacuum coating equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com