Multifunctional solar cell roof structure

A technology of solar cells and roof structures, which is applied in the directions of solar thermal power generation, solar thermal energy, solar thermal collectors, etc., can solve the problems that it is difficult to meet the cost of convenient disassembly and assembly, reliable quality and high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

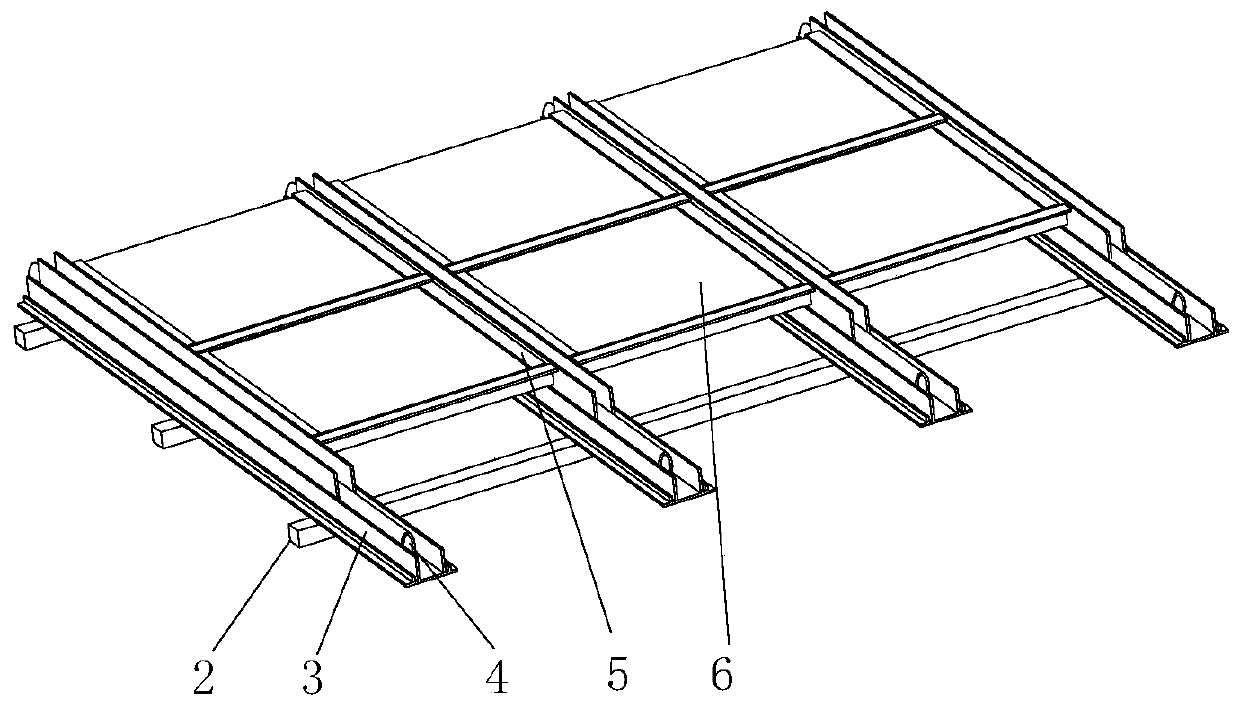

[0029] Example 1, such as figure 1 Shown:

[0030] A multifunctional solar cell roof structure comprising:

[0031] There are multiple longitudinal beams 3, and the multiple longitudinal beams 3 are equidistantly and obliquely fixed to the multiple roof beams 2, and the longitudinal beams 3 are provided with longitudinal grooves 31;

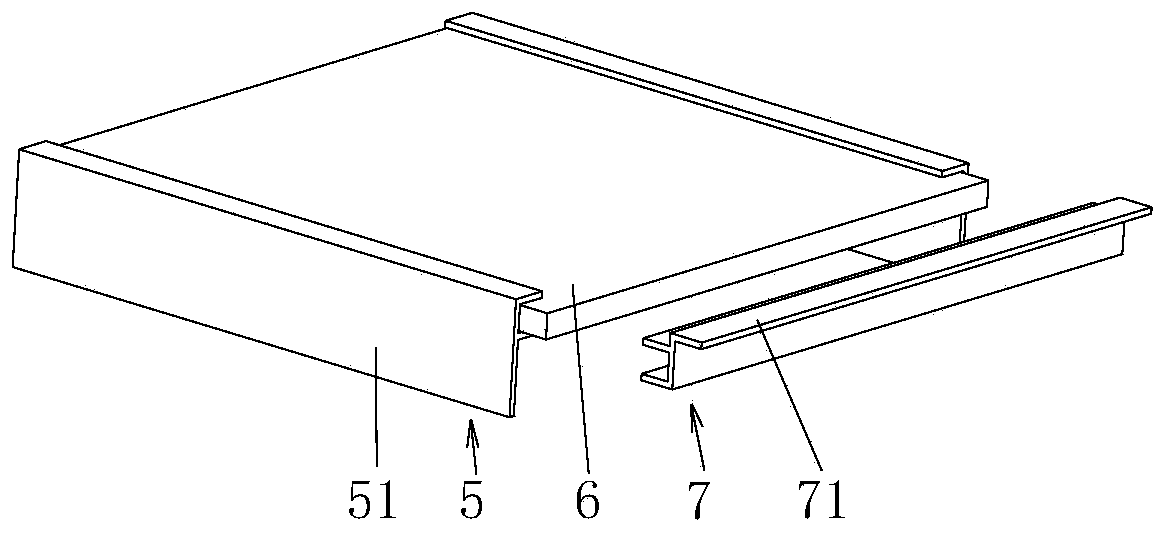

[0032] There are multiple solar cell assemblies, each solar cell assembly is provided with a solar cell 6, symmetrical side frames 5 are respectively installed on both sides of the solar cell 6, the side frame 5 is provided with a side plate 51, and the bottom side of the solar cell 6 A base frame 7 is installed, and the base frame 7 is provided with a bottom plate 71, and multiple solar cell assemblies can be installed between two adjacent longitudinal beams 3. Among multiple solar cell assemblies in the same column, the bottom plate 71 of the upper solar cell assembly can Covering the top of the solar cell module below, in the same row of sol...

Embodiment 2

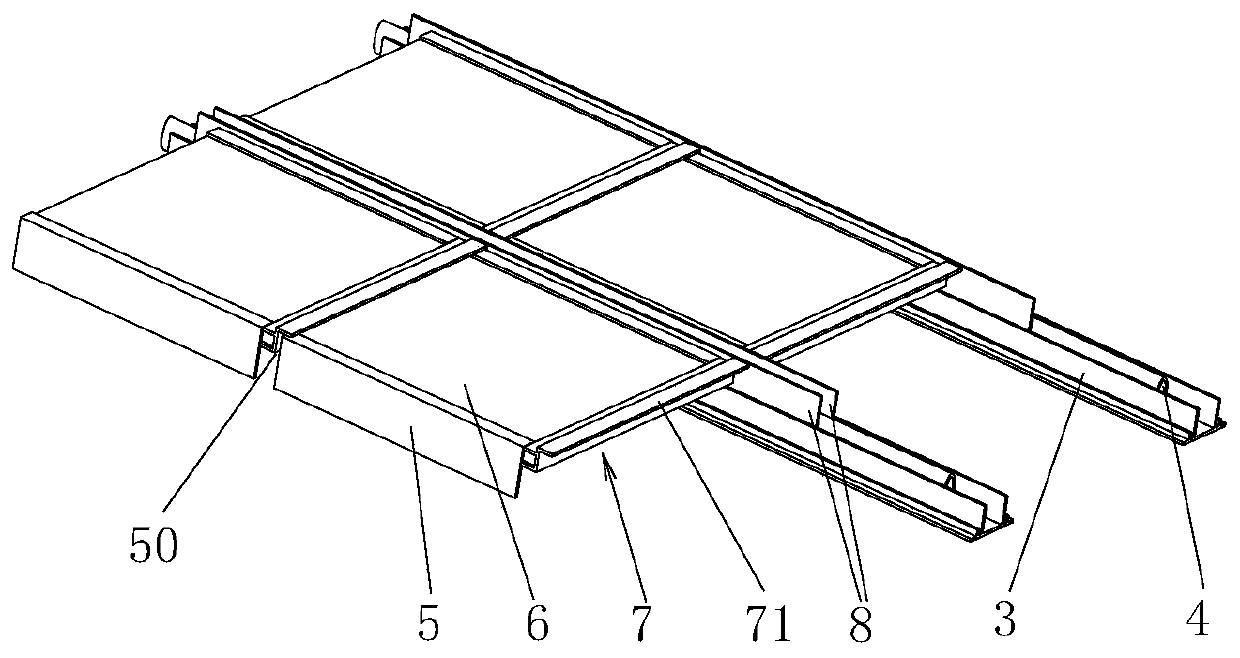

[0036] Example 2, such as figure 2 , 3 and 4 as shown:

[0037] We know that the fixed elastic strip will reduce its elasticity after aging for a long time, thereby affecting the installation firmness of the solar cell module. In order to solve this technical problem, on the basis of embodiment 1, the elastic strip 4 is an elastic tube. The round tube, the elastic tube is filled with liquid and / or gas and can generate pressure, which can further compress the side plate 51 of the solar cell module and the side wall of the longitudinal groove 31 .

[0038] It should be noted that both ends of the elastic tube can be sealed after being pressurized and filled with liquid and / or gas, such as through a bulky head seal, and the elastic tube can be a silicon rubber tube, etc., which is resistant to high temperature and has a long service life.

[0039] In addition, the pressure of the elastic tube can increase the elastic force of the elastic tube, thereby prolonging the service li...

Embodiment 3

[0042] Example 3, such as Figure 5 Shown:

[0043] In order to adjust the pressure conveniently, on the basis of Example 2, the elastic tube is connected with a pressure regulating device. When the solar cell module needs to be disassembled, the pressure can be reduced through the pressure regulating device. Under normal conditions, the pressure regulating device can increase the pressure through the elastic tube. .

[0044] Further, the pressure regulating device includes:

[0045] The first sealing tube 41 communicates with one end of a plurality of elastic tubes through the interface;

[0046] The second sealing tube 45 communicates with the other end of the plurality of elastic tubes through the interface;

[0047] An air bag 44, which communicates with the first sealed tube 41 or the second sealed tube 45 via a pipeline, the air bag 44 is filled with liquid and / or gas, and the air bag 44 is placed on the platform;

[0048] The weight 42 is pressed on the air bag 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com