Treatment system for spraying tower sewage in automobile painting workshop and treatment method thereof

A technology of treatment system and spray tower, which is applied in the field of treatment system of spray tower sewage in automobile painting workshop, can solve the problems of reduced paint adsorption capacity and increased VOCs treatment cost, so as to save treatment costs, reduce treatment costs, and be economical. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

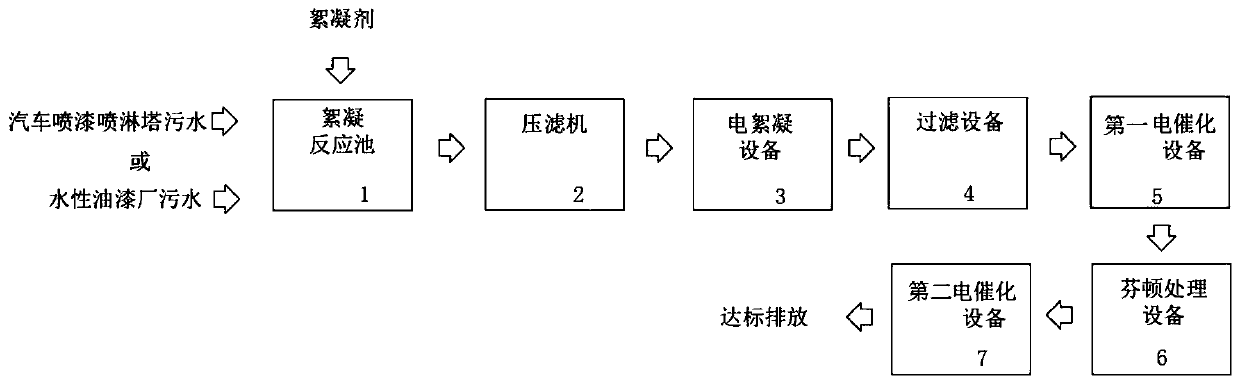

Method used

Image

Examples

Embodiment 1

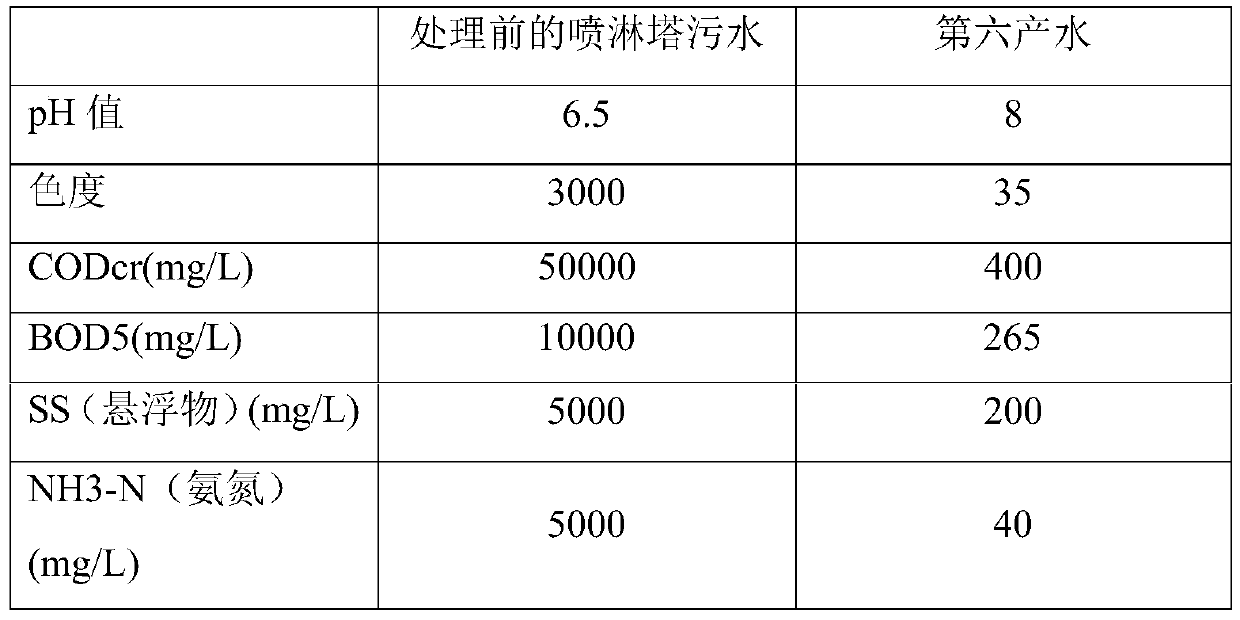

[0067] The COD of the spray tower sewage of a company's automobile painting workshop is 50000mg / L, and the daily production is 5m 3 / d. Adopt the treatment system of the present invention to process sewage, steps and produced water COD value are as follows:

[0068] (1) Input the sewage from the spray tower of the automobile painting workshop into the flocculation reaction tank 1, and the amount of flocculant added is 2000g / t. During the reaction process, continuous stirring was required, and after the reaction was completed, it was left to settle for 30 minutes to obtain the first product water.

[0069] (2) Input the first produced water into the filter press 2, the filtration accuracy of the filter press is 5 μm, and the water inlet flow rate is 0.3m 3 / h, the second product water and solid particles are obtained after pressure filtration.

[0070] (3) Input the second produced water into the electrocoagulation device 3, the anode of the device is an aluminum electrode, ...

Embodiment 2

[0080] For the sewage discharged by the same company, flocculation reaction, electrocoagulation reaction, electro-Fenton treatment and electrocatalytic treatment are carried out in sequence. After adding flocculant and filtering, the COD of the first product water obtained is ≤ 30000mg / L; after electrocoagulation and filtration, the COD of the third product water is ≤ 10000mg / L; the COD of the fourth product water obtained after Fenton treatment is ≤ 7500mg / L; After 1 hour of normal electrocatalysis, the COD of the sixth product water obtained can be degraded by 80-90%, that is, COD≤1125mg / L, which cannot meet the emission standard.

[0081]If emission standards need to be met, the catalytic time must be increased. Due to the high power of catalytic equipment and the increase of catalytic time, it not only affects the treatment capacity of sewage in the system, but also increases the treatment cost. Therefore, it is necessary to carry out the electrocatalytic reaction before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com