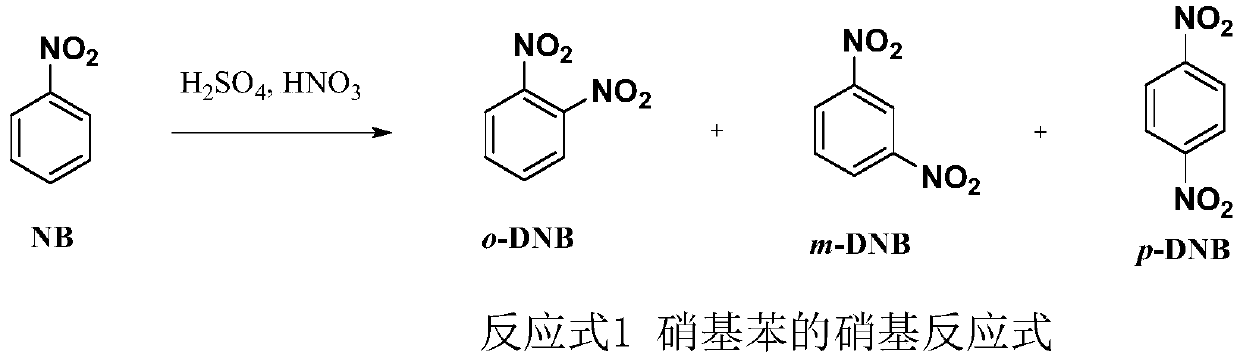

Method for nitrifying nitrobenzene by using micro-channel continuous flow reactor

A technology of p-nitrobenzene and a reactor is applied in the field of nitration of p-nitrobenzene by using a microchannel continuous flow reactor, and can solve the problems of increased dilute sulfuric acid treatment capacity, increased sulfuric acid consumption, low availability and the like, Achieve the effect of reducing pollution, prolonging service life and low corrosion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mixed acid preparation: Mix 92% sulfuric acid and 65% nitric acid to get mixed acid, wherein the molar ratio of nitric acid to sulfuric acid is 1:4.

[0039] Set the temperature of the external heat exchanger to 85°C, that is, the preheating temperature is 85°C, so that the circulation temperature of the system reaches equilibrium.

[0040] The nitrobenzene and the mixed acid are respectively passed into the preheating module through the tetrafluoro advection pump for preheating, and then enter the reaction module of the microchannel continuous flow reactor. Adjust the flow rate of nitrobenzene to 1.7mL / min, adjust the flow rate of mixed acid to 5.1mL / min, make the molar ratio of nitrobenzene to nitric acid 1:1.05, control the residence time of reactants in the reactor to 80s, and let the reaction products flow into the collection tank , in order to make the reaction run continuously for 24 hours, there are 6 collection tanks in this example, each collection tank contin...

Embodiment 2

[0044] Mixed acid preparation: Mix 92% sulfuric acid and 65% nitric acid to get mixed acid, wherein the molar ratio of nitric acid to sulfuric acid is 1:5.

[0045] Set the temperature of the external heat exchanger to 85°C so that the circulating temperature of the system reaches equilibrium.

[0046] The nitrobenzene and the mixed acid are respectively passed into the preheating module through the tetrafluoro advection pump for preheating, and then enter the reaction module of the microchannel continuous flow reactor. Adjust the flow rate of nitrobenzene to 1.8mL / min, adjust the flow rate of mixed acid to 7.7mL / min, make the molar ratio of nitrobenzene to nitric acid 1:1.25, control the residence time of reactants in the reactor to 56s, and let the reaction products flow into the collection tank , In this example, the reactants collected continuously for 4 hours were collected, cooled to 50-60°C, added o-nitrotoluene, stirred evenly, cooled naturally, and left to stand for 1...

Embodiment 3

[0050] Mixed acid preparation: Mix 92% sulfuric acid and 65% nitric acid to get mixed acid, wherein the molar ratio of nitric acid to sulfuric acid is 1:6.

[0051] Set the temperature of the external heat exchanger to 85°C so that the circulating temperature of the system reaches equilibrium.

[0052] The nitrobenzene and the mixed acid are respectively passed into the preheating module through the tetrafluoro advection pump for preheating, and then enter the reaction module of the microchannel continuous flow reactor. Adjust the flow rate of nitrobenzene to 1.9mL / min, adjust the flow rate of mixed acid to 8.0mL / min, make the molar ratio of nitrobenzene to nitric acid 1:1.05, control the residence time of reactants in the reactor to 55s, and let the reaction products flow into the collection tank , continuously collected the reactants for 4 hours, cooled to 50-60°C, added p-difluorobenzene, stirred evenly, cooled naturally, and stood for 1 hour. The lower inorganic phase flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com