Crystalline calcium-based microporous framework material and preparation method thereof

A frame material, calcium-based technology, applied in the field of crystalline calcium-based microporous frame material and its preparation, can solve the problems of the humectant being unable to build a microporous structure, unstable water locking performance, weak water storage capacity, etc. It is suitable for large-scale popularization and application, the preparation method is simple and diverse, and the effect of promoting moisturizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Another aspect of the present invention provides a method for preparing a crystalline calcium-based microporous framework material, wherein the preparation method for a calcium-based microporous framework material in a single crystal state comprises the following steps:

[0048] 1) Prepare 1.5mol / L calcium salt solution A1 and stir at room temperature for 10 minutes;

[0049] 2) Prepare 2mol / L solution B1 of 1,3,5-tris(4-carboxy-substituted phenyl)benzene ligand, and stir at room temperature for 10 minutes;

[0050] 3) Mix solution A1 and solution B1, and stir at room temperature for 30 minutes to obtain mixed solution C1;

[0051] 4) Transfer the solution C1 to a stainless steel reaction kettle lined with a polytetrafluoroethylene liner, seal it, and react at T°C for t hours;

[0052] 5) Naturally cool to room temperature after the reaction, filter and wash to obtain a single crystal calcium-based microporous framework material.

[0053] In step (1), the calcium salt...

Embodiment 1

[0067] Embodiment 1 Preparation of crystalline calcium-based microporous framework material

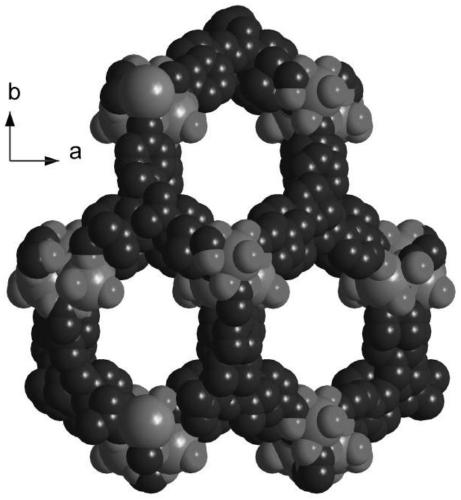

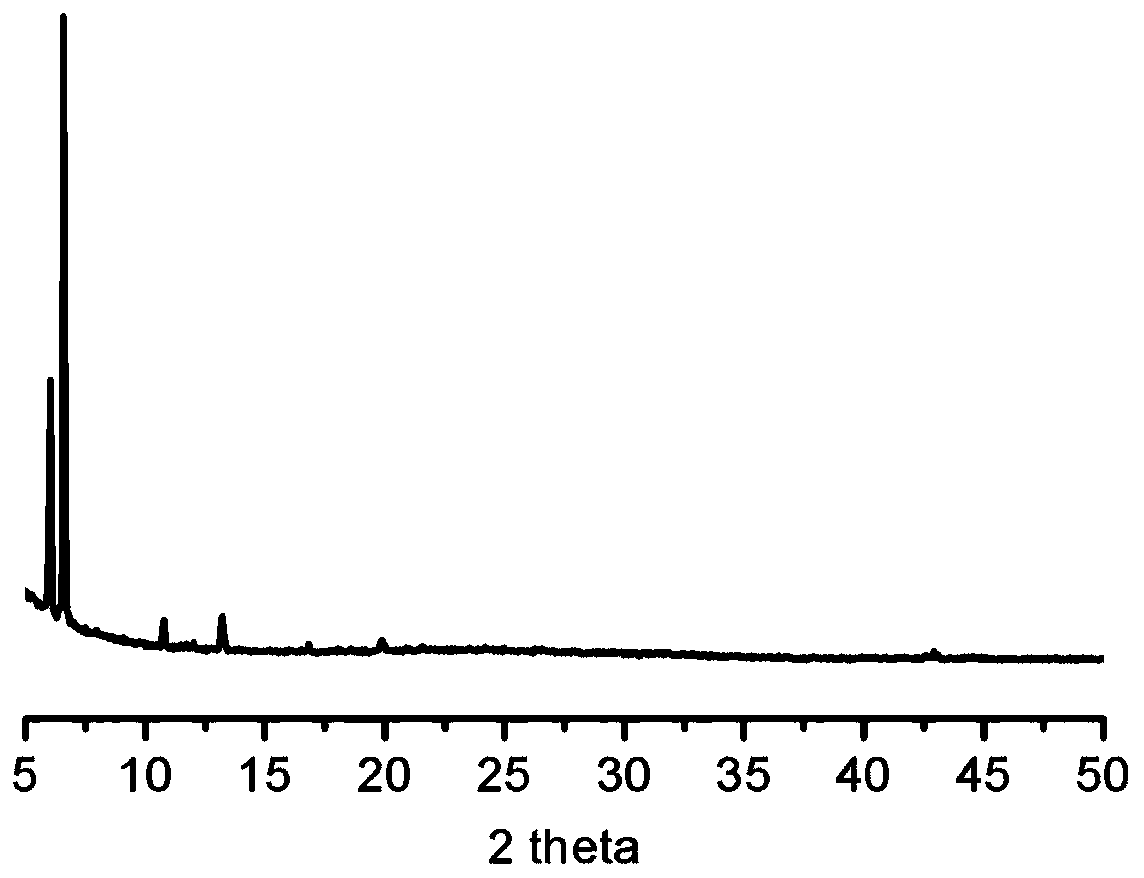

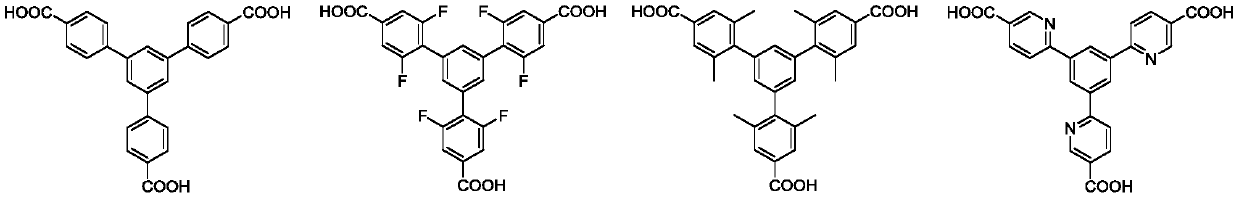

[0068] Dimethylacetamide and water (volume ratio 8:2) solution A with 1.5mol / L calcium chloride, and dimethylacetamide with 2mol / L 1,3,5-tris(4-carboxyphenyl)benzene Amide and water (volume ratio 8:2) solution B, the above two solutions were mixed in a volume ratio of 1:1, stirred for 30 minutes, then the mixed solution was transferred to a stainless steel reaction kettle lined with a polytetrafluoroethylene liner, React at 120°C for 72 hours, cool naturally, filter, wash, and dry to obtain a rod-shaped crystalline calcium-based microporous framework material, the molecular structure of which is shown in Figure 1, according to the formula: The calculated yield is 78% (mass of the calcium substance in the medium)*100. The calcium substance in the product in this embodiment is a crystalline calcium-based microporous framework material, and the calcium substance in the feed is calcium ch...

Embodiment 2

[0069] Embodiment 2 Preparation of crystalline calcium-based microporous framework material

[0070] Configure solution C of 1.5mol / L calcium nitrate in dimethylformamide and water (volume ratio 8:2), configure 2mol / L 1,3,5-tri(4-carboxy-2,6-difluorobenzene base) dimethylformamide of benzene and water (volume ratio 8:2) solution D, the above two solutions were mixed at a volume ratio of 1:1, stirred for 30 minutes, and then the mixed solution was transferred to the liner polytetrafluoroethylene In a stainless steel reactor with an inner tank, react at 90°C for 24 hours, cool naturally, filter, wash, and dry to obtain a rod-shaped crystalline calcium-based microporous framework material. According to the formula (the quality of the calcium substance in the product / the quality of the calcium substance in the feed)*100, the calculated yield is 51%. In this embodiment, the calcium substance in the product is a crystalline calcium-based microporous framework material, and the calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com