Silane-terminated resin for sealant and preparation method thereof

A silane-capped and sealant technology, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of high dynamic viscosity of products, expensive raw materials, and complicated preparation technology of silane-capped resins. It achieves the effects of low dynamic viscosity, simple and environmentally friendly preparation process, and shortened raw material supply chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

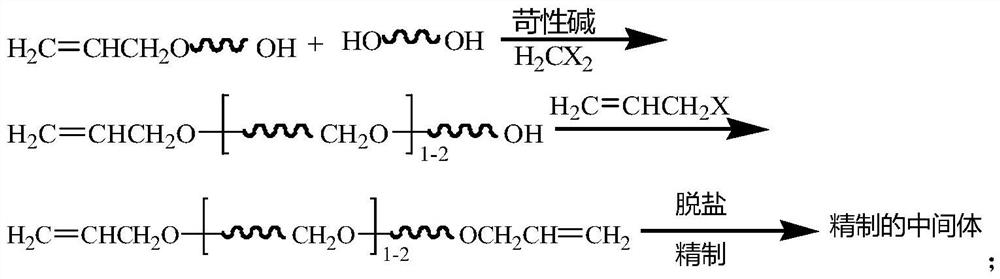

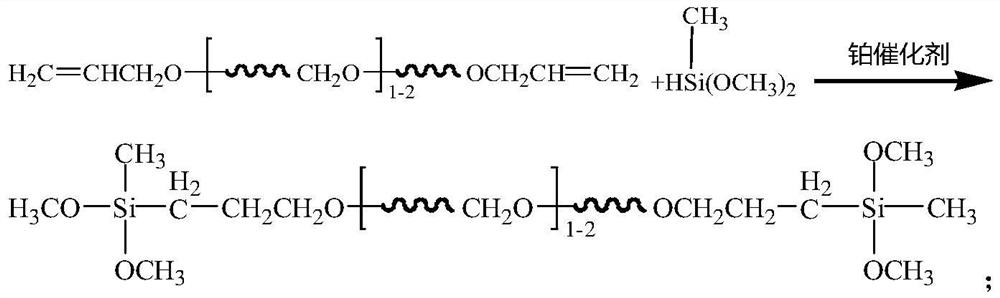

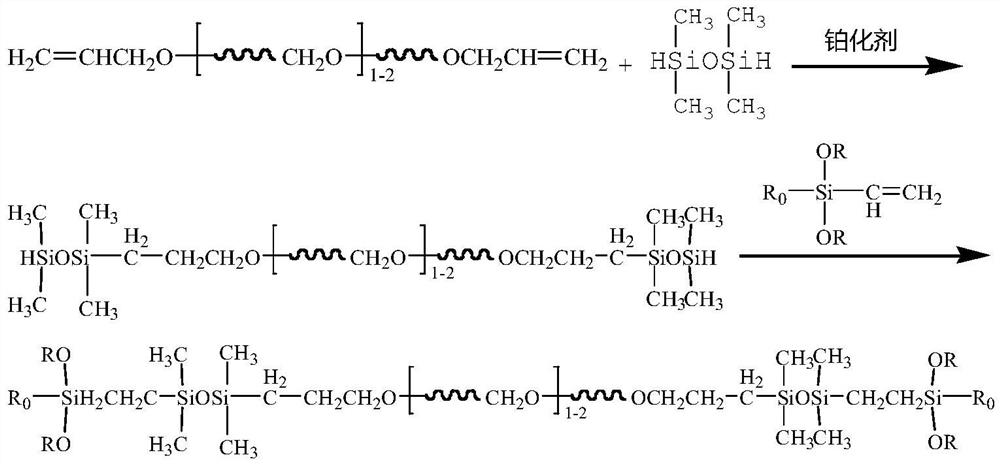

Method used

Image

Examples

Embodiment 1

[0059] A kind of silane-terminated resin for sealant, its preparation method comprises the following steps:

[0060] S1: Add 1 part of hydroxymethyltriethoxysilane and 80ppm double metal cyanide (DMC) catalyst to the 2.5L high-pressure glass reactor in sequence, completely replace the air in the high-pressure glass reactor with nitrogen, and raise the temperature to 150 while stirring. ℃, first add 0.5 parts of propylene oxide to initiate the reaction, when the temperature rise rate in the reactor exceeds 0.1 °C / s and the pressure begins to drop, start to continuously add the remaining 34.5 parts of propylene oxide, and after the addition is completed, keep it at 150 ° C for 2 hour, the pressure was constant at this time, and vacuum degassed for 20 minutes to obtain a monosiloxane-based polyether intermediate;

[0061] S2: Lower the temperature in the high-pressure glass reactor to 80°C, then transfer all the monosiloxane-based polyether intermediates prepared in S1 into the n...

Embodiment 2

[0066] A kind of silane-terminated resin for sealant, its preparation method comprises the following steps:

[0067] S1: Add 1 part of hydroxymethyltriethoxysilane and 80ppm double metal cyanide (DMC) catalyst to a 2.5L high-pressure glass reactor in sequence, completely replace the air in the high-pressure glass reactor with nitrogen, stir and heat up to 150°C , add 0.5 parts of propylene oxide to initiate the reaction. When the temperature rise rate in the reactor exceeds 0.1°C / s and the pressure begins to drop, start to continuously add the remaining 34.5 parts of propylene oxide. At this time, the pressure was constant, and vacuum degassed for 20 minutes to obtain a monosiloxane-based polyether intermediate;

[0068] S2: Lower the temperature in the high-pressure glass reactor to 90°C, transfer all the monosiloxane-based polyether intermediates prepared in S1 into the normal-pressure reactor, and add 200ppm stannous octoate-triethylenediamine Composite catalyst, heat up w...

Embodiment 3

[0074] A kind of silane-terminated resin for sealant, its preparation method comprises the following steps:

[0075] S1: Add 1 part of hydroxymethyltriethoxysilane and 80ppm double metal cyanide (DMC) catalyst to a 2.5L high-pressure glass reactor in sequence, completely replace the air in the high-pressure glass reactor with nitrogen, stir and heat up to 150°C, First add 0.5 parts of propylene oxide to initiate the reaction. When the temperature rise rate in the reactor exceeds 0.1°C / s and the pressure begins to drop, start to add the remaining propylene oxide continuously. Keep the pressure constant, vacuumize and degas for 20 minutes to obtain a monosiloxane-based polyether intermediate;

[0076] S2: Lower the temperature in the high-temperature glass reactor to 90°C, then transfer all the monosiloxane-based polyether intermediates prepared in S1 into the normal-pressure reactor, and add 200ppm stannous octoate-triethylene di Amine composite catalyst (mass ratio of stannou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com