Honeycomb briquette containing sulfur-fixing combustion-supporting additive and preparation method thereof

An additive and briquette technology, which is applied in the field of briquette containing sulfur-fixing and combustion-supporting additives and its preparation, can solve the problems of complex formula, high cost and high usage of raw materials, and achieve the effect of improving the efficiency of sulfur fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

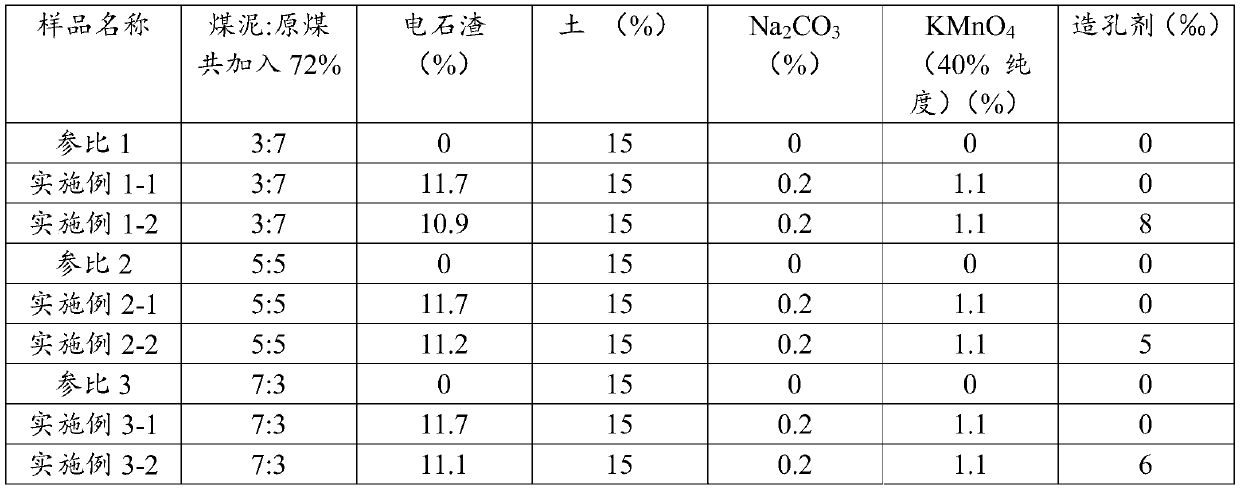

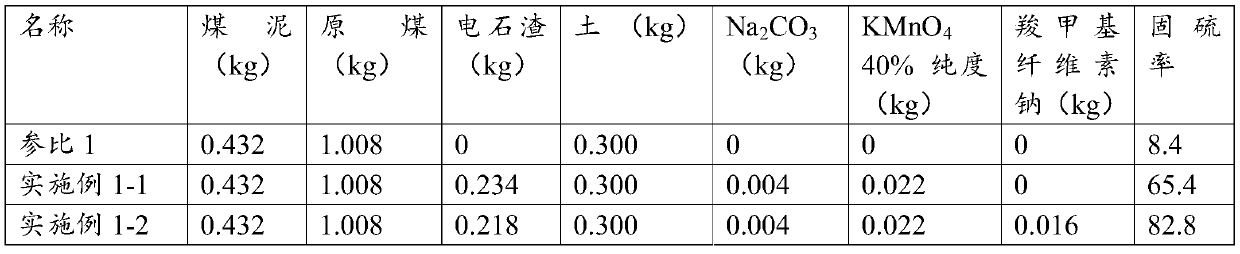

[0027] Embodiment 1 (weight ratio 3:7 of coal slime and raw coal):

[0028]

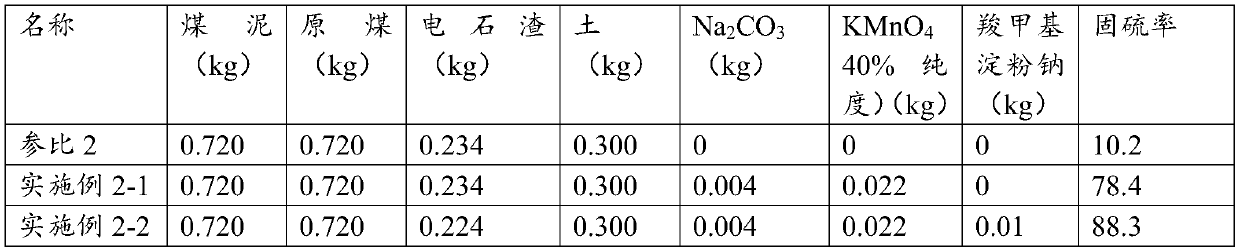

[0029] Case 2 (the weight ratio of coal slime to raw coal is 5:5):

[0030]

[0031] Case 3 (the weight ratio of coal slime to raw coal is 7:3)

[0032]

[0033] From the above examples, it can be seen that after adding the pore-forming agent, the sulfur fixation rate of honeycomb briquettes is increased by 10-18% compared with the sample without adding the pore-forming agent. Show that this method is feasible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com