Cement self-desulfurization device and method

A self-desulfurization and cement technology, which is applied in the field of cement manufacturing, can solve problems such as difficult operation, low desulfurization efficiency, and high equipment investment, and achieve the effects of improving sulfur fixation efficiency, reducing investment costs, and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

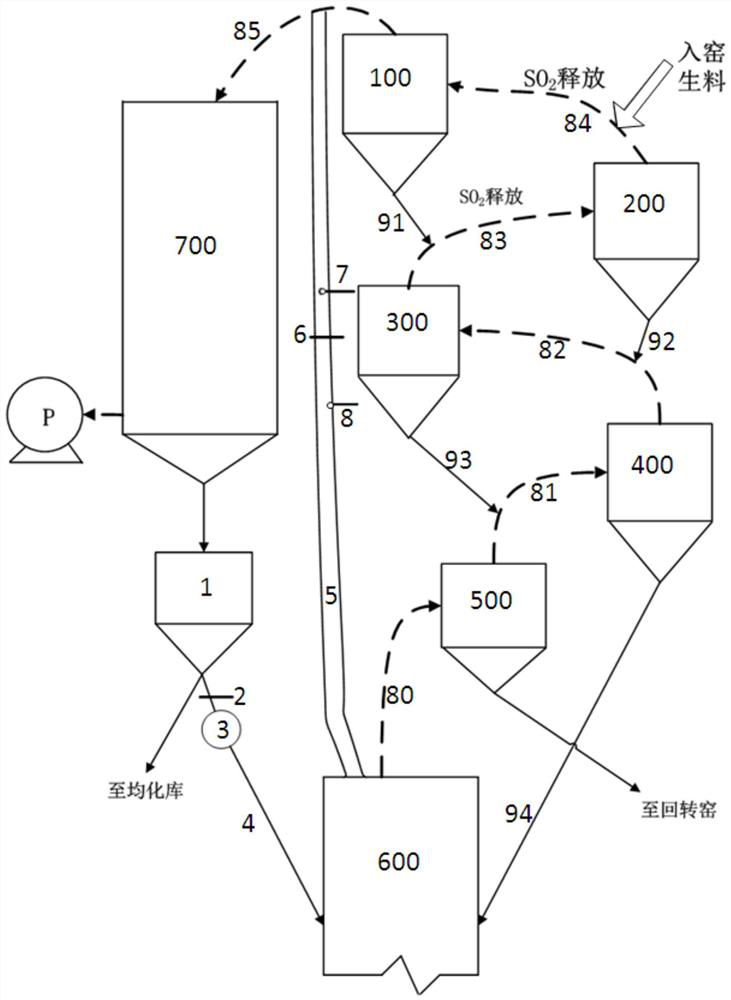

Method used

Image

Examples

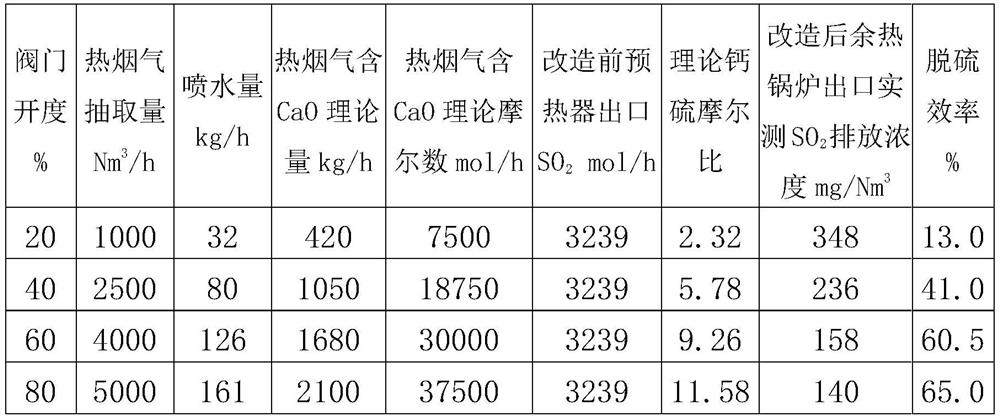

Embodiment 1

[0068] 5000T / D cement production line, preheater export SO 2 Emission concentration is 400mg / nm 3 (2. Rehabilitate the concentration of 10% oxygen, the same as the same); after the raw material grinding sulfur, the chimney exit O 2 10% concentration, SO 2 Emission concentration is 200mg / nm 3 . In order to put SO 2 Control at 100 mg / nm 3 Within, the technical solution described in this patent is used to modify the system. Increasing the thermoforgia extracting pipe leading from the export of a separate furnace, that is, the flue gas extraction pipe and the flue gas valve, the diameter of the flue gas extraction pipe is φ600mm, the extracted hot flue gas is directly connected to the top premium preheater Export pipeline; the internal wall of the export pipe of the most superior preheater is incorporated into V. 2 O 5 The mass fraction is 0.5%; the water sprinkle is added to the thermos of the flue gas extraction pipe, allowing the flue gas moisture volume fraction to 8%; adj...

Embodiment 2

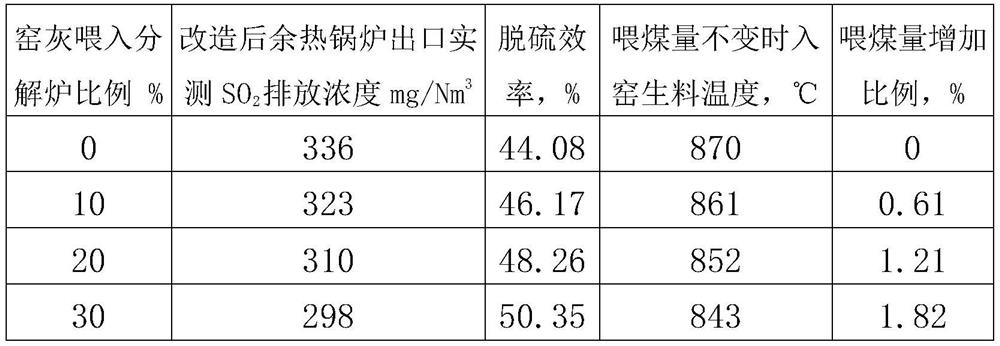

[0076] 2500T / d cement production line, preheater export SO 2 Emission concentration is 600mg / nm 3 (2. Rehabilitate the concentration of 10% oxygen, the same as the same); after the raw material grinding sulfur, the chimney exit O 2 10% concentration, SO 2 Emission concentration is 350mg / nm 3 . In order to reduce SO 2 The emission level is modified using the technical solution described in this patent. Increasing the flue gas extraction pipe and flue gas valve from the outlet of the split furnace, the diameter of the flue gas extraction pipe is φ500mm, the extracted thermal pan gas directly accesses the most superior preheater export pipe; the superior preheating Inner wall of the export pipe is incorporated into V 2 O 5 The mass fraction is 0.5%; the water sprinkle is added to the flue gas extraction official road, so that the flue gas moisture volume fraction is controlled at 8%; the kiln gray collected by the remaining hot boiler is partially sent into the decomposition fu...

Embodiment 3

[0084] In the same embodiment, the inner wall of the exit pipe of its most superior preheater is not coated into V. 2 O 5 Pouring tab. At this time, the cement production self-desulfurization process and the actual effect of the device are shown in Table 3 at the time of different valve opening.

[0085] Table 3 Cement production self-desulfurization process and actual effect of the device

[0086]

[0087] As can be seen from Table 3, when the least coated V in the outer pretty preheater outlet pipe 2 O 5 Time, more than the first embodiment, the desulfurization efficiency is significantly reduced. When the valve opening degree is 20%, its desulfurization efficiency is only 81% of Example 1 under the same conditions; when the valve opening degree is 60%, the desulfurization efficiency is only 83% of Example 1 under Example 1 under the same conditions. From this, it can be seen that the outer wall coating of the first-level preheater outlet conduit in the patent of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com